Electrolytic bath for aluminium electrolysis and electrolysis technology using same

An electrolytic cell and electrolytic aluminum technology, applied in the field of electrolytic process and electrolytic aluminum electrolytic cell, can solve the problems of low oxidation resistance of oxide film, large power consumption of electrolytic aluminum process, and high overvoltage of alloy anode, and achieve overvoltage Low, high oxidation resistance, low power consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

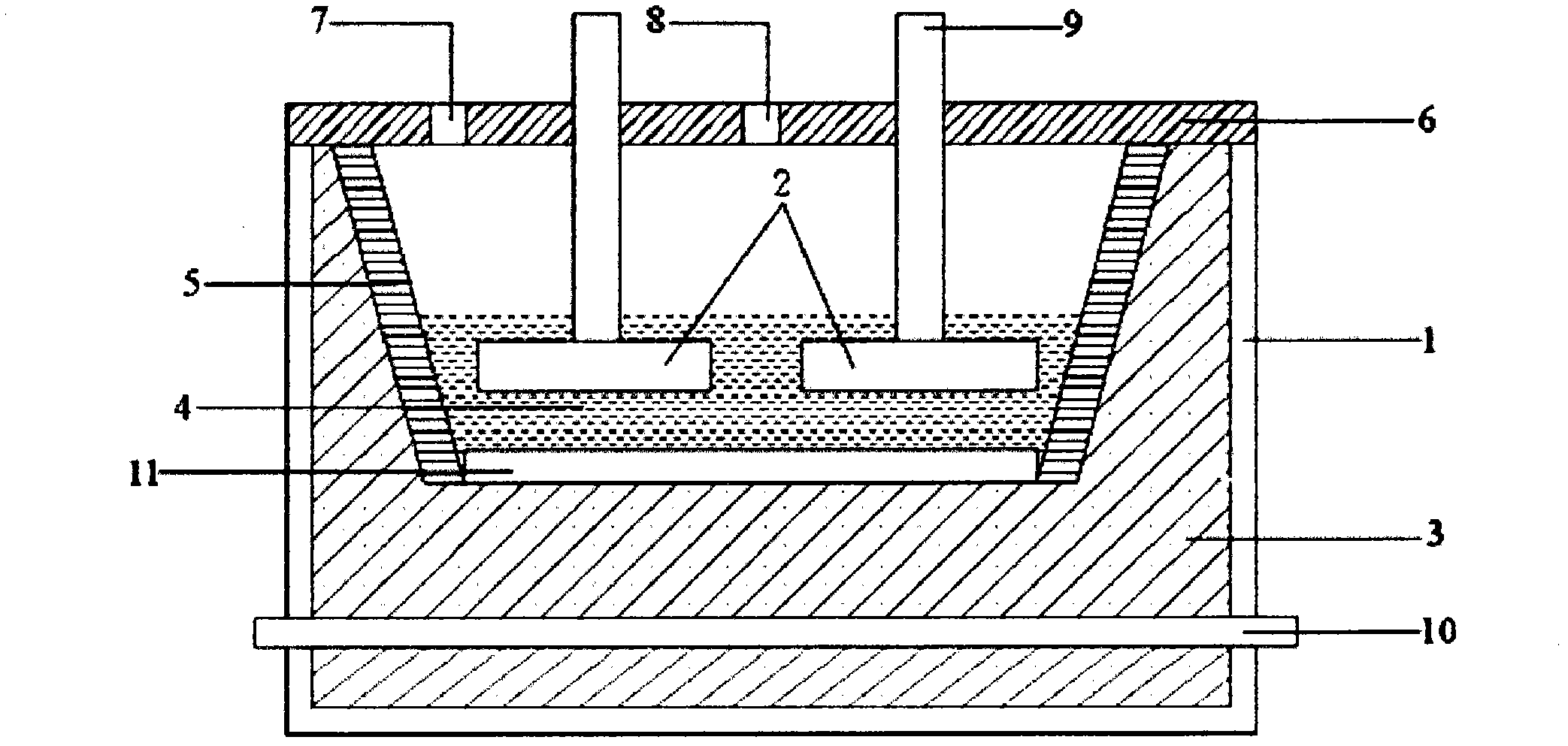

Image

Examples

Embodiment 1

[0049] Fe, Cu, Ni and Sn metal blocks are mixed according to the ratio of 23wt% Fe, 60wt% Cu, 14wt% Ni and 3wt% Sn, heated to a molten state at high temperature and then cast to obtain the anode 1 . The density of anode 1 is 8.3g / cm 3 , the specific resistance is 68μΩ·cm, and the melting point is 1360°C.

[0050] The composition of the electrolyte in the present embodiment is: NaF, 32%; AlF 3 , 57%; LiF, 3%; KF, 4%; Al 2 o 3, 4%, where NaF and aluminum fluoride AlF 3 The molar ratio is 1.12. The initial crystallization temperature of the electrolyte in this example was determined to be 640°C. The conductivity of the electrolyte ≈1.7Ω -1 cm -1 , density ≈2.03g / cm 3 , the saturation concentration of alumina is 5%.

[0051] The technique of using the electrolytic cell electrolytic aluminum of the present invention is:

[0052] (1) Using the anode 1 and the carbon body cathode, the above-mentioned amount of NaF, AlF 3 , LiF, KF, Al 2 o 3 First melt in the melting furn...

Embodiment 2

[0056] Fe, Cu, Ni and Sn metal blocks are mixed according to the ratio of 40wt% Fe, 36wt% Cu, 19wt% Ni and 5wt% Sn, heated to a molten state at high temperature and cast to obtain the anode 2 . The density of the anode is 8.1g / cm 3 , the specific resistance is 76.8μΩ·cm, and the melting point is 1386°C.

[0057] The composition of the electrolyte in the present embodiment is: NaF, 38%; AlF 3 , 50%; LiF, 2%; KF, 5%; Al 2 o 3 , 5%, where NaF and aluminum fluoride AlF 3 The molar ratio is 1.52.

[0058] The performance of the electrolyte described in this embodiment was measured, and the result is that the primary crystal temperature of the electrolyte in this embodiment is 670°C. Electrolyte conductivity ≈1.8Ω -1 cm -1 , Density ≈2.05g / cm 3 , the saturation concentration of alumina is 6%.

[0059] The technique of using the electrolytic cell electrolytic aluminum of the present invention is:

[0060] (1) Using the anode 2 and the carbon body cathode, the above-mentione...

Embodiment 3

[0064] Fe, Cu, Ni and Sn metal blocks are mixed according to the ratio of 25wt% Fe, 46.8wt% Cu, 28wt% Ni and 0.2wt% Sn, heated to a molten state at high temperature and cast to obtain the anode 3 . The density of the anode is 8.2g / cm 3 , the specific resistance is 72μΩ·cm, and the melting point is 1350°C.

[0065] The composition of the electrolyte in the present embodiment is: NaF, 32%; AlF 3 , 57%; LiF, 3%; KF, 4%; Al 2 o 3 , 4%, where NaF and aluminum fluoride AlF 3 The molar ratio is 1.12.

[0066] The performance of the electrolyte described in this example was measured, and the result is that the primary crystal temperature of the electrolyte in this example is 640°C. The conductivity of the electrolyte ≈1.6Ω -1 cm -1 , density ≈2.03g / cm 3 , the saturation concentration of alumina is 5%.

[0067] The technique of using the electrolytic cell electrolytic aluminum of the present invention is:

[0068] (1) adopt the anode 3 and the carbon body cathode, the above-m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com