High temperature organic solvent exhaust-gas treatment apparatus

A waste gas treatment device and organic waste gas technology, applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems of organic waste gas emission polluting the environment, low purity of recovered solvents, and high moisture content of solvents, and achieve quality stability Good, simple and safe operation process, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

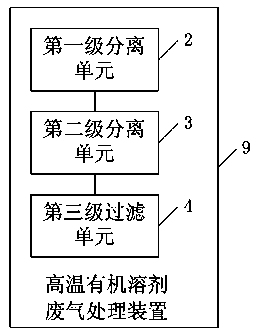

[0046] see figure 1 , the present invention provides a first embodiment of a high-temperature organic solvent waste gas treatment device 9, including:

[0047] A first-stage separation unit 2 for carrying out first-stage separation of organic waste gas;

[0048]Connected with the first-stage separation unit 2, and used to carry out the second-stage separation of the organic waste gas after the first-stage separation; the second-stage separation unit 3;

[0049] Connected to the second-stage separation unit 3, a third-stage filter unit 4 for performing third-stage filtration treatment on the organic waste gas after the second-stage separation.

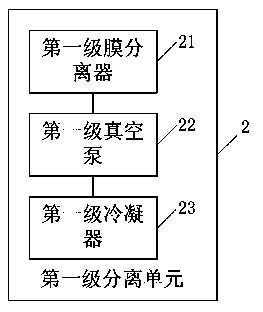

[0050] see figure 2 , the first-stage separation unit 2 includes:

[0051] The first-stage membrane separator 21 used to perform the first-stage separation treatment of the organic waste gas, and the first-stage membrane separator 21 selects a polymer membrane or an inorganic membrane.

[0052] It should be noted that the polymer m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com