Fruit juice milk beverage and preparation method thereof

A milk drink and fruit juice technology, which is applied in the field of juice milk drink and its preparation, can solve the problems of milk protein variability, high sugar content, product viscosity, etc., and achieve the effects of good stability, long shelf life and good flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

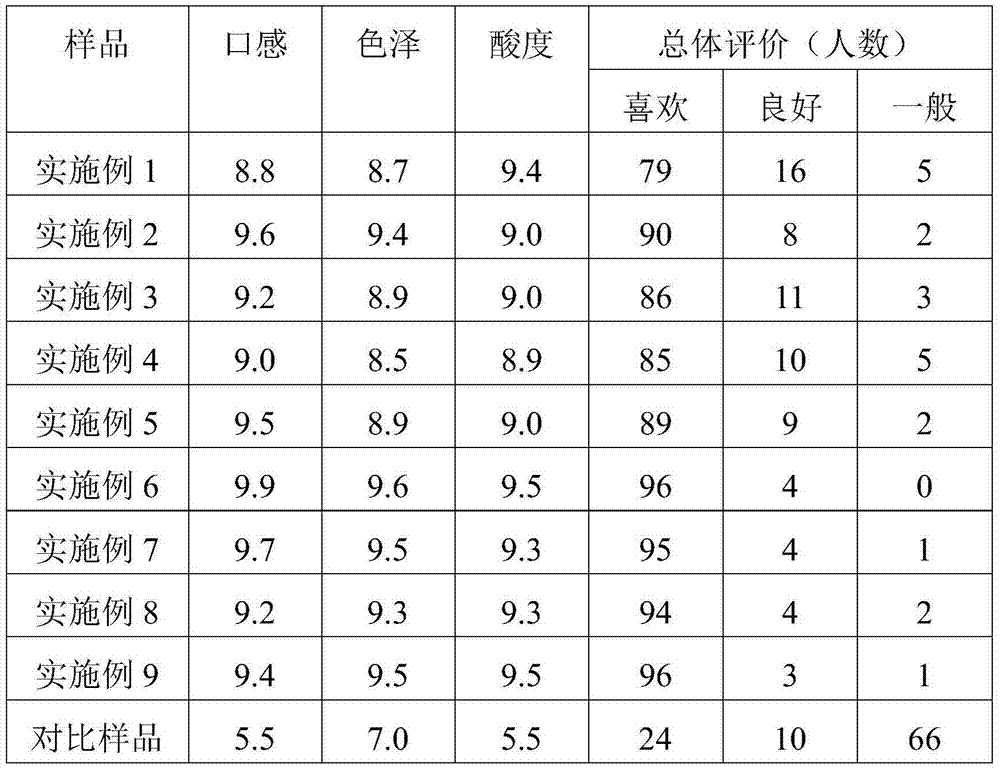

Examples

Embodiment 1

[0056] 1. Raw material formula (see Table 1):

[0057] The raw material formula of table 1 embodiment 1

[0058] raw material

technical indicators

Amount added (wt%)

F≥3.1%, P≥2.9%, SNF≥8.1

35

Prickly Pear Juice

pH3.5~4.5

10

pear juice concentrate

35~55°Brix, pH 3.5~4.5

1

green tea extract

Tea polyphenols≥25%

0.06

Vitamin C

0.015

0.05

Sweetener (Aspartame)

0.02

Carrageenan GENU Hi-pHive

food grade

0.3

food grade

0.13

water

53.575

total

100

[0059] 2. Preparation method:

[0060] (1) Stir and mix sweetener, carrageenan, water, disodium hydrogen phosphate and raw milk at 70-75°C for 20 minutes until evenly mixed, and then grind and refine with a colloid mill at 70-75°C to obtain the material liquid A;...

Embodiment 2

[0066] 1. Raw material formula (see Table 2):

[0067] The raw material formula of table 2 embodiment 2

[0068] raw material

technical indicators

Amount added (wt%)

raw milk

F≥3.1%, P≥2.9%, SNF≥8.1

40

Prickly Pear Juice

pH3.5-4.5

20

apple juice concentrate

40~60°Brix, pH 3.5-4.5

2.5

Tea polyphenols≥25%

0.05

Vitamin C

food grade

0.03

food grade

0.075

Sweeteners (Steviol Glycosides)

food grade

0.025

Carrageenan GENU Hi-pHive

food grade

0.2

food grade

0.1

water

37.12

total

100

[0069] 2. Preparation method:

[0070] (1) Stir and mix sweetener, carrageenan, water, sodium bicarbonate and raw milk at 70-75°C for 15 minutes until the mixture is uniform, then grind and refine it with a colloid mill at 70-75°C to obtain a liquid A;...

Embodiment 3

[0075] 1. Raw material formula (see Table 3):

[0076] The raw material formula of table 3 embodiment 3

[0077] raw material

technical indicators

Amount added (wt%)

raw milk

F≥3.1%, P≥2.9%, SNF≥8.1

50

Prickly Pear Juice

pH3.5~4.5

30

Mango Concentrate

45~65°Brix, pH 3.0~4.0

5

Tea polyphenols≥25%

0.06

Vitamin C

food grade

0.05

Sodium citrate

food grade

0.1

Sweetener (cyclamate)

food grade

0.025

Carrageenan GENU Hi-pHive

food grade

0.3

food grade

0.13

water

14.465

total

100

[0078] 2. Preparation method:

[0079] (1) Stir and mix sweetener, carrageenan, water, sodium citrate and raw milk at 70-75°C for 15 minutes until evenly mixed, then grind and refine it with a colloid mill at 70-75°C to obtain a liquid A; Immediately cool the liquid A (<10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com