Ecological and energy-saving solar greenhouse of composite mud wall-canopy structure

A technology of canopy structure and solar greenhouse, which is applied in the field of ecological energy-saving solar greenhouse, can solve the problems of low land utilization rate, good light transmission, and inability to produce all year round, etc., so as to improve the utilization rate of sunlight and increase the angle of sunlight incidence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following examples illustrate the invention in detail. Various raw materials and various equipments used in the present invention are conventional market products, and can be purchased directly from the market.

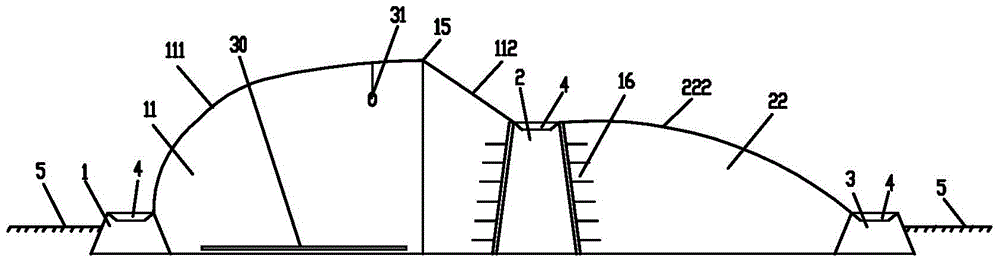

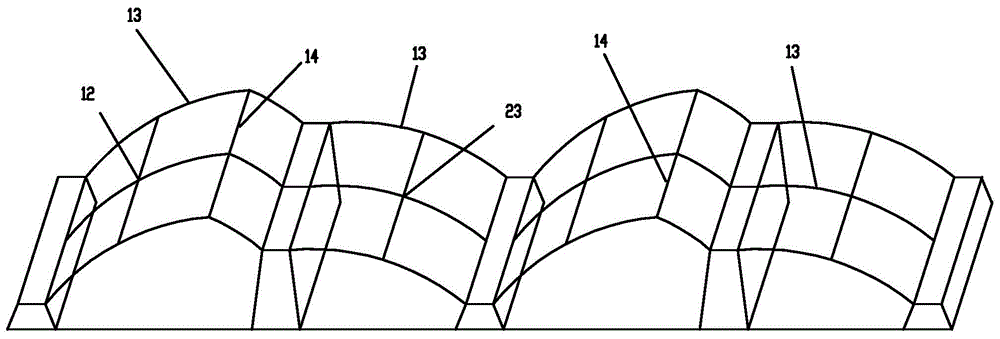

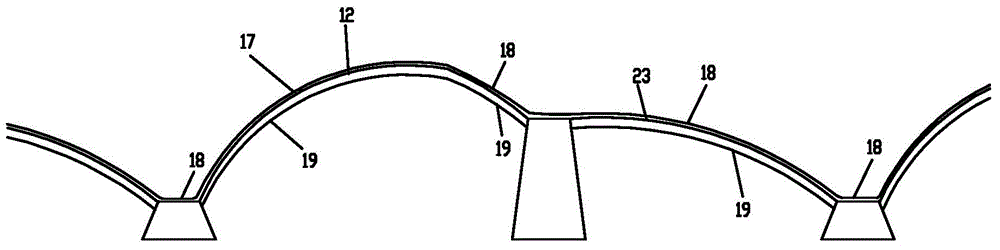

[0046]Referring to the accompanying drawings, the structure of a specific embodiment of the present invention includes a plurality of groups of greenhouse units connected to each other; The wall 2 and the back wall 3 are arranged sequentially from south to north, the awning 11 is set between the front wall 1 and the middle wall 2, and the shade shed 22 is set between the middle wall 2 and the back wall 3; The east gable and west gable in the north-south direction; the front wall 1 and the rear wall 3 are the front and rear shared walls of the two adjacent greenhouse units, that is, the rear wall 3 of the greenhouse unit on the south side is the front wall 1 of the greenhouse unit on the north side; The front wall 1 and the rear wall 3 are semi-underground....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com