A shaft sealing device for a high speed turbine-generator used in orc

A high-speed generator and main shaft sealing technology, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of main shaft leakage and air leakage, and achieve the effects of reducing wind loss, ensuring thermal safety, sealing performance, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

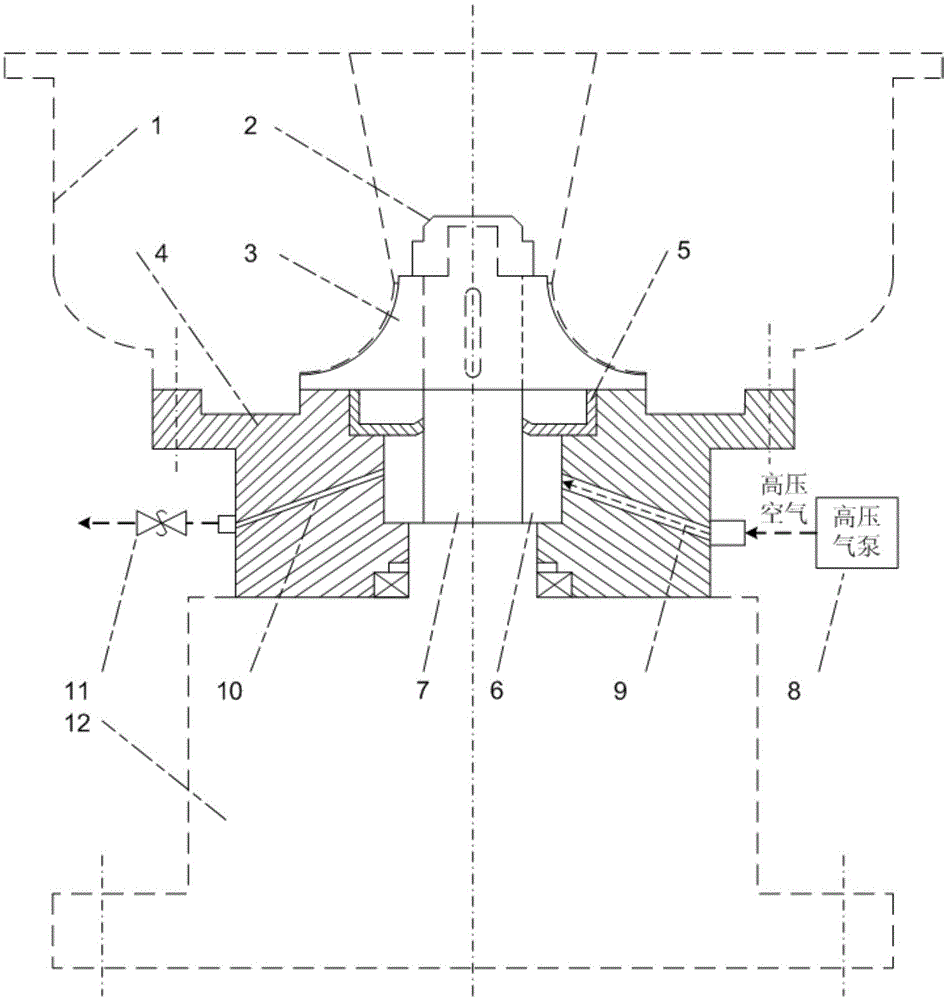

[0017] ORC is one of the key technologies to recover the waste heat energy of the internal combustion engine and improve the efficiency of the internal combustion engine. Among them, the expander is the thermal power conversion component in the ORC system and one of the core components of the low-power ORC. High-speed turboexpander is the best choice because of its excellent performance at low flow rate and large expansion ratio. The present invention will be further described below in conjunction with a specific embodiment of a high-speed turbine-generator applied to an ORC system for recovering waste heat energy of an internal combustion engine.

[0018] As shown in the accompanying drawings, the present invention provides a high-speed turbine-generator shaft sealing device applied to ORC, which aims to solve the problem of large wind loss of the generator caused by the shaft blow-by of the high-speed turbine-generator. The problem of serious heating and low efficiency incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com