A self-locking head structure for screen

A self-locking head and screen technology, applied in optics, instruments, projection devices, etc., can solve the problems of poor self-locking structure stability, high production cost, poor convenience, etc., and achieve strong self-locking stability, low production cost, and structure. unique effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below according to the drawings and embodiments.

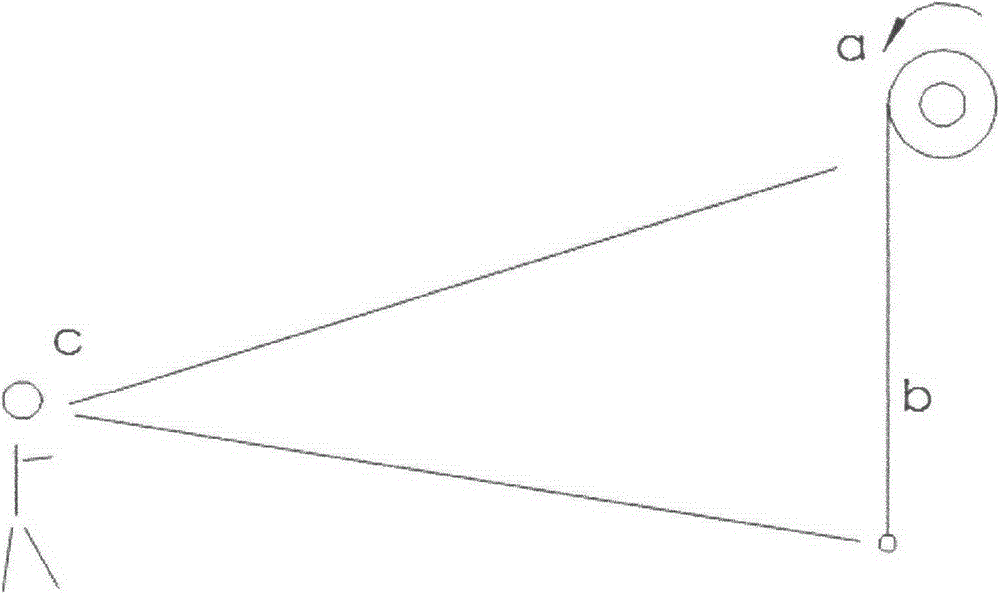

[0029] In order to facilitate the understanding and description of the specific implementation of the present invention, in the pull-down process of the screen, it is generally understood as using such as figure 1 As shown in the more common counterclockwise way of turning a and pulling down the screen b, the demo audience c of the screen is located at figure 1 On the left side of screen b.

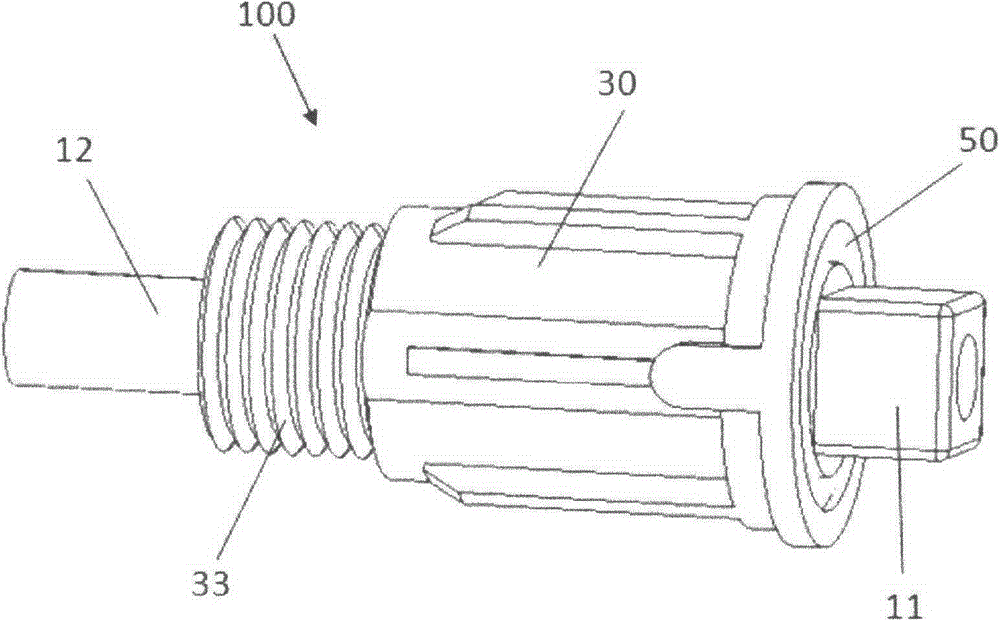

[0030] combine figure 2 As shown, when the demo audience c is facing the screen b, a self-locking head structure 100 for the screen according to the present invention is installed at the left end of the screen reel d.

[0031] Such as image 3 , Figure 5 and Figure 7 , Figure 8 , Figure 9 As shown, a self-locking head structure 100 for a screen according to the embodiment of the present invention includes a rotating shaft 10 having a screen connecting portion 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com