Durability test system and high-efficiency consistency test method for electrical appliance sockets

A test system and durability technology, applied in the direction of instruments, measuring electronics, measuring devices, etc., can solve problems such as arcing, cumbersome operation, and endangering personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

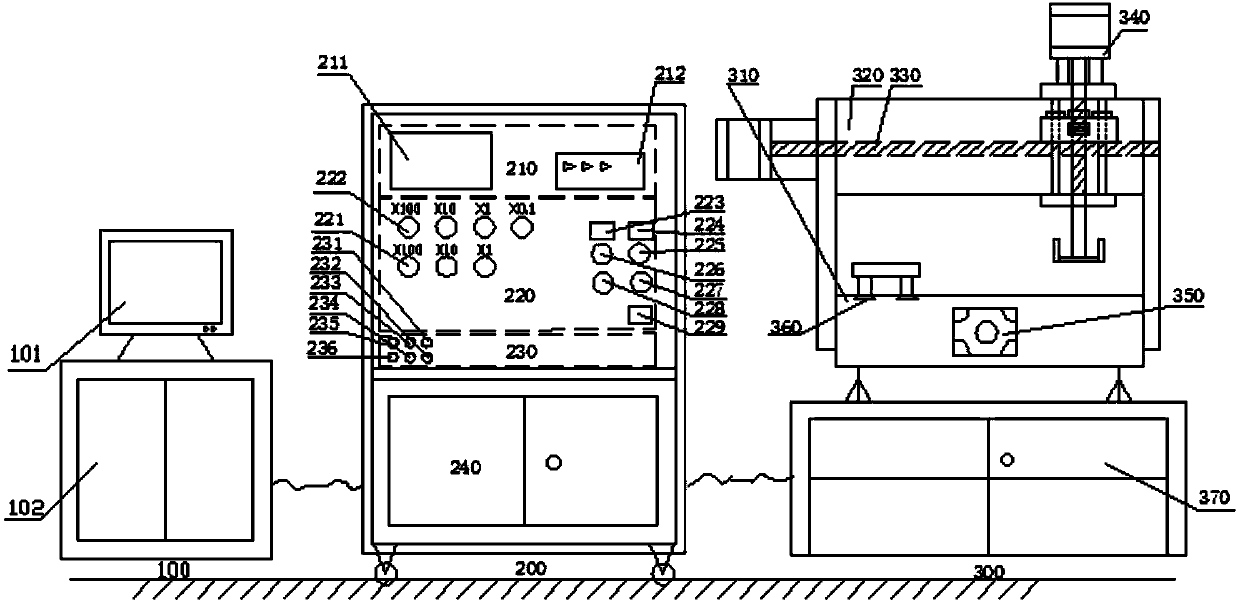

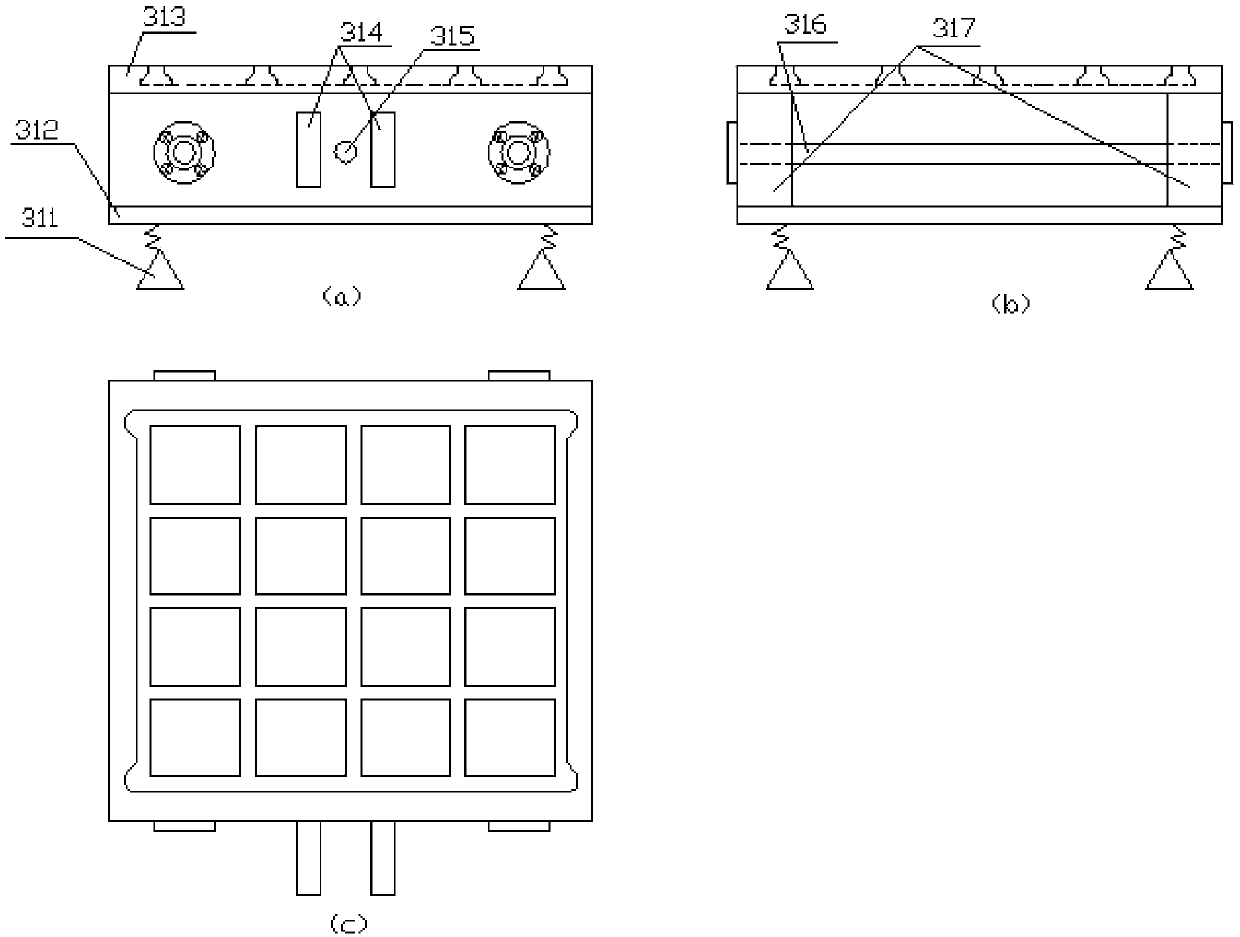

[0061] like figure 1As shown, the durability test system of household and similar electrical sockets of the present invention is composed of a host computer control device 100, a lower computer control device 200 and an execution operation device 300; the execution operation device 300 is connected with the lower computer control device 200, and the lower computer control device The device 200 is connected with the upper computer control device 100 .

[0062] The upper computer control device 100 includes an industrial computer 101 and a lower cabinet 102; the industrial computer 101 is placed on the top of the lower cabinet 102 and connected to the PLC of the lower computer control device 200 through the RS485 interface. 101 power supply.

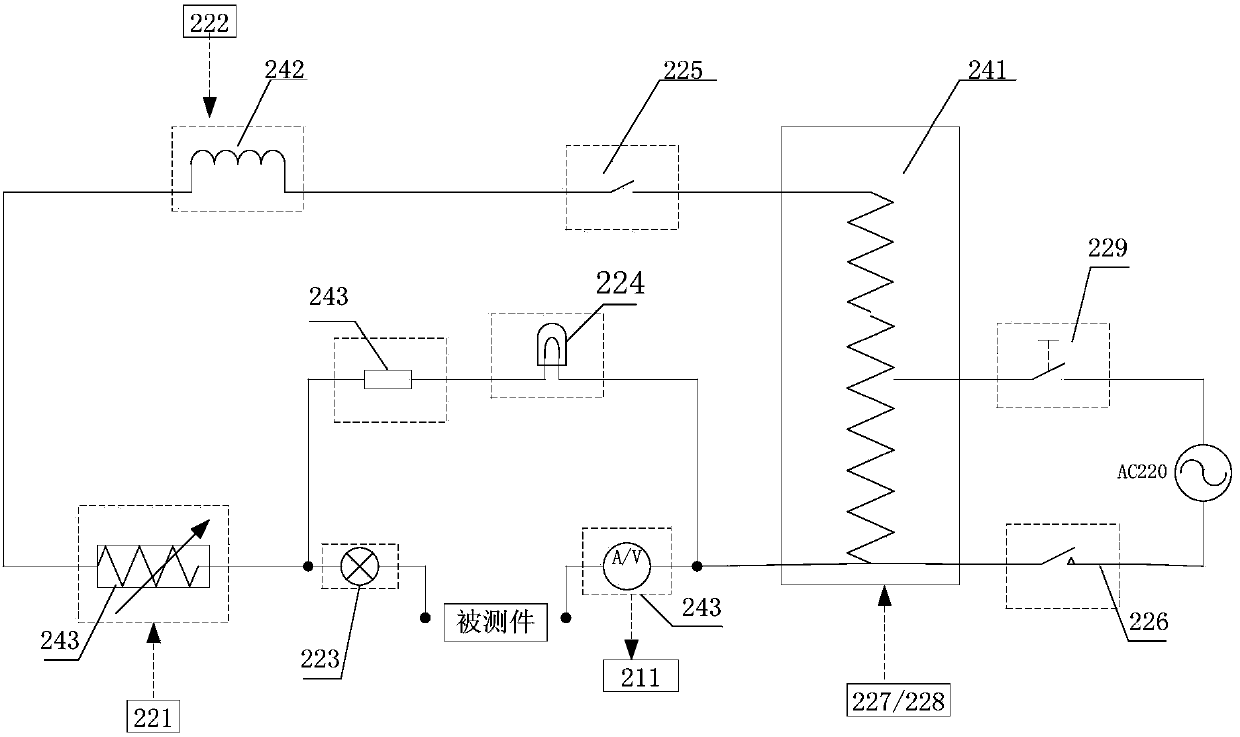

[0063] The lower computer control device 200 includes a display unit 210, a control unit 220, a three-axis jogging unit 230, and a lower computer control cabinet 240; the display unit 210 is located on the upper part of the lower computer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com