Laser tracking measurement system having spherical revolution bounce error compensation function and compensation method thereof

A technology of laser tracking measurement and spherical surface rotation, which is used in measuring devices, mapping and navigation, and optical devices, etc., can solve the problems of high precision spherical surface rotation, difficult processing and manufacturing, large errors, etc., to reduce the difficulty of processing and manufacturing. Cost, simple structure, and the effect of reducing measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

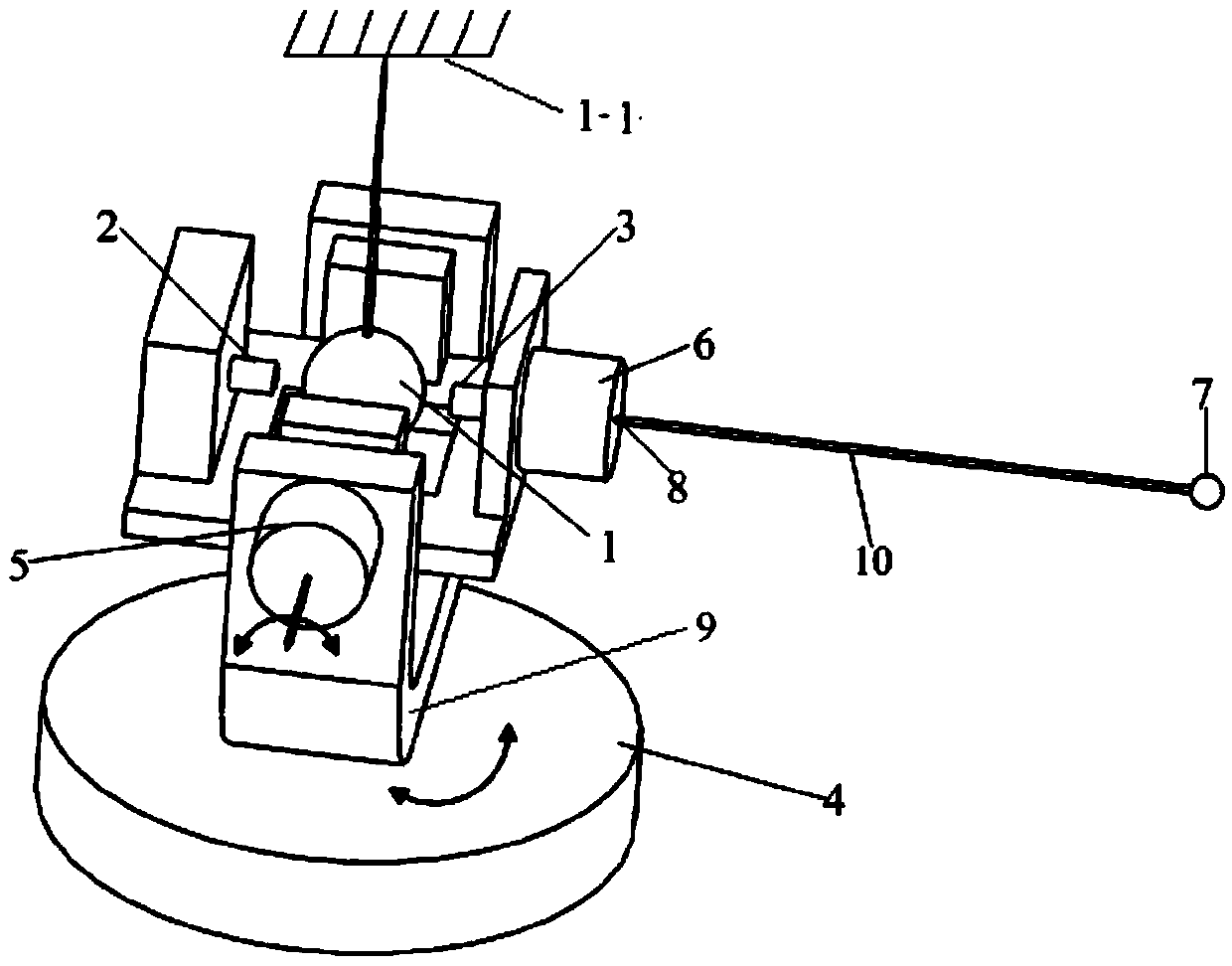

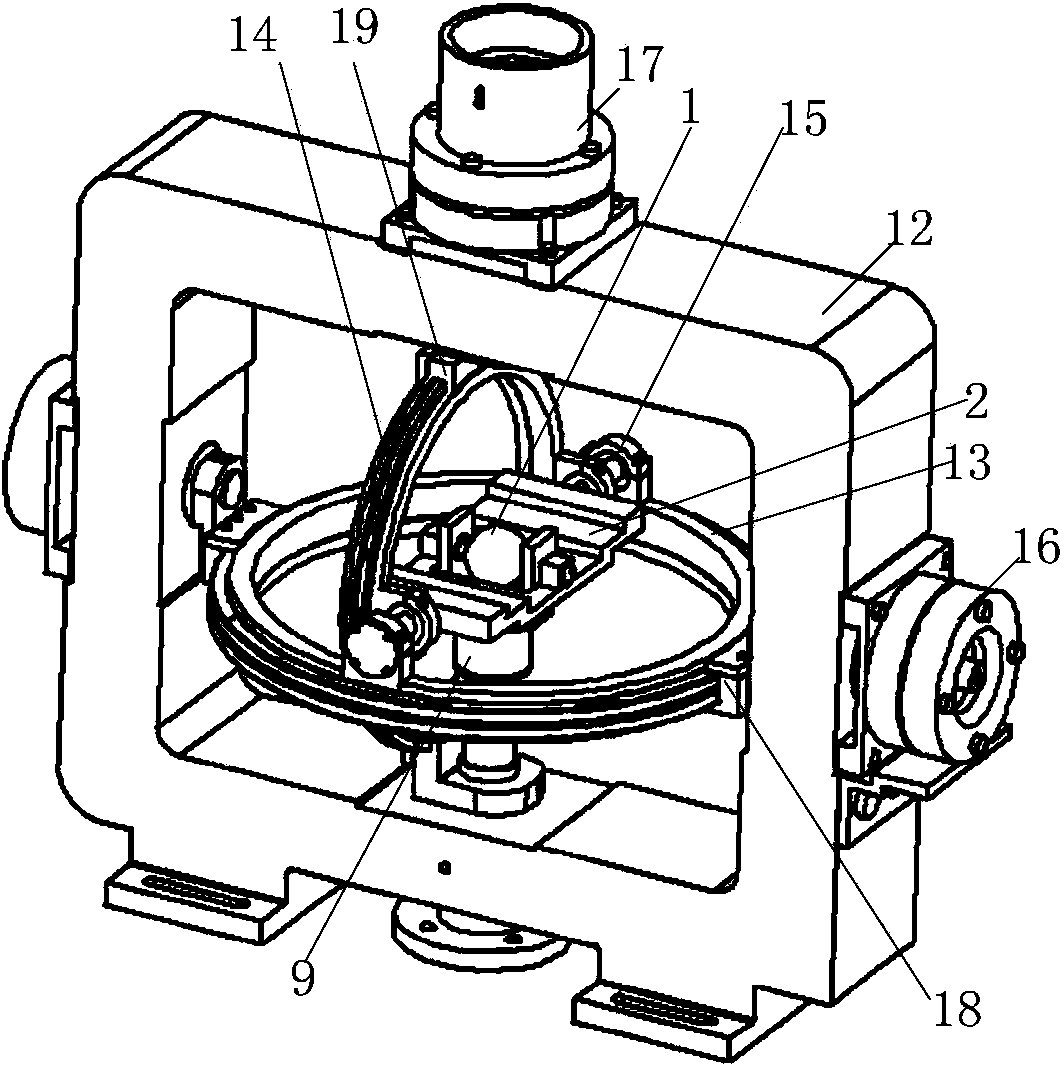

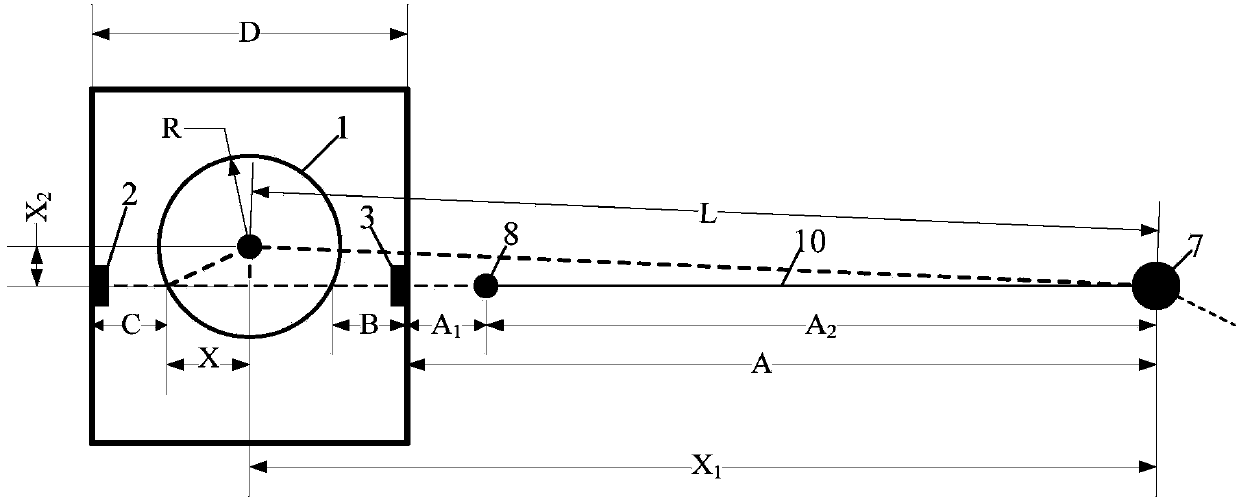

[0033] Such as figure 1 As shown, the present invention provides a series laser tracking measurement system with spherical gyration runout error compensation function, comprising: a horizontal turntable 4 placed on the desktop, a support 9 is installed on the horizontal turntable 4, and a spherical gyration is installed on the support 9 mechanism, the spherical gyration mechanism includes a standard ball 1, a support plate 11 with a central opening, a first displacement sensor 2, a second sensor 3, and a laser head 6, wherein the standard ball 1 is arranged at the center of the support 9, and the support plate 11 The central opening of the standard ball 1 is installed on the bracket 9 after passing through the standard ball 1, and the first displacement sensor 2, the second sensor 3, and the laser head 6 are installed on the support plate 11, wherein the first displa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com