Coreless air pressure thermal-insulating pouring furnace

A pouring furnace and air pressure technology, which is applied in the field of coreless air pressure heat preservation pouring furnace, can solve the problems of low thermal efficiency, inability to meet the needs of modern industrial production, uneven heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

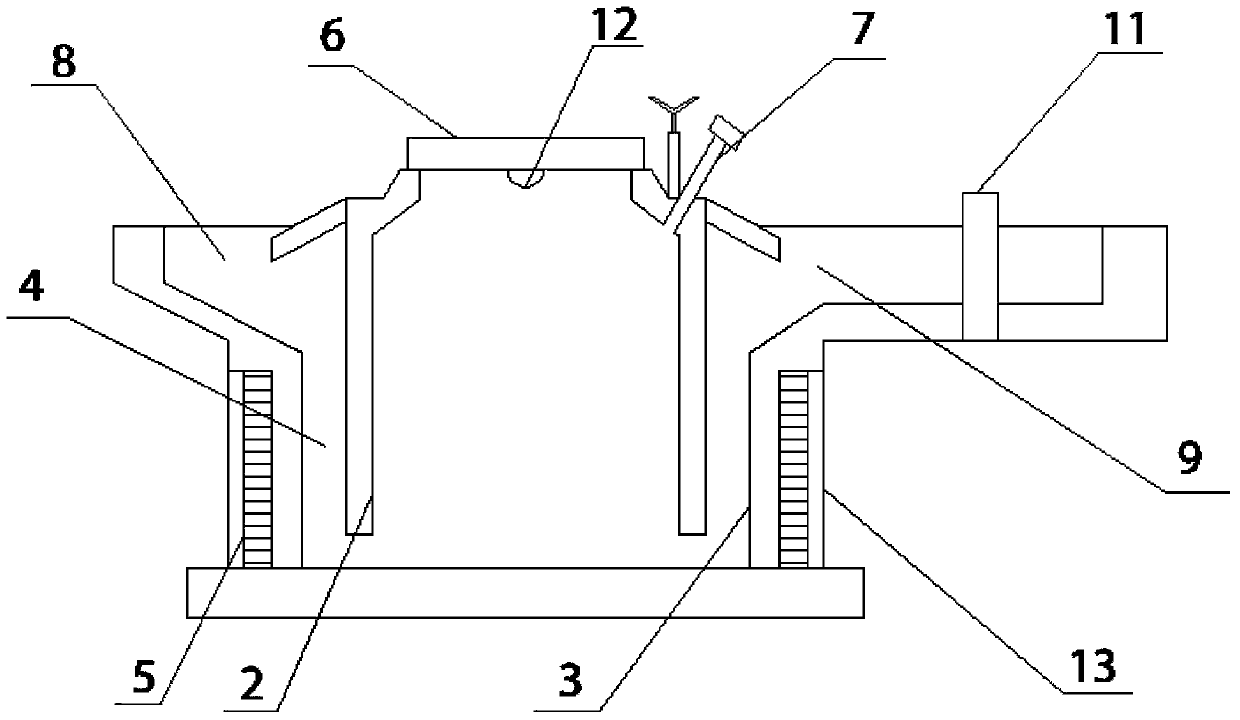

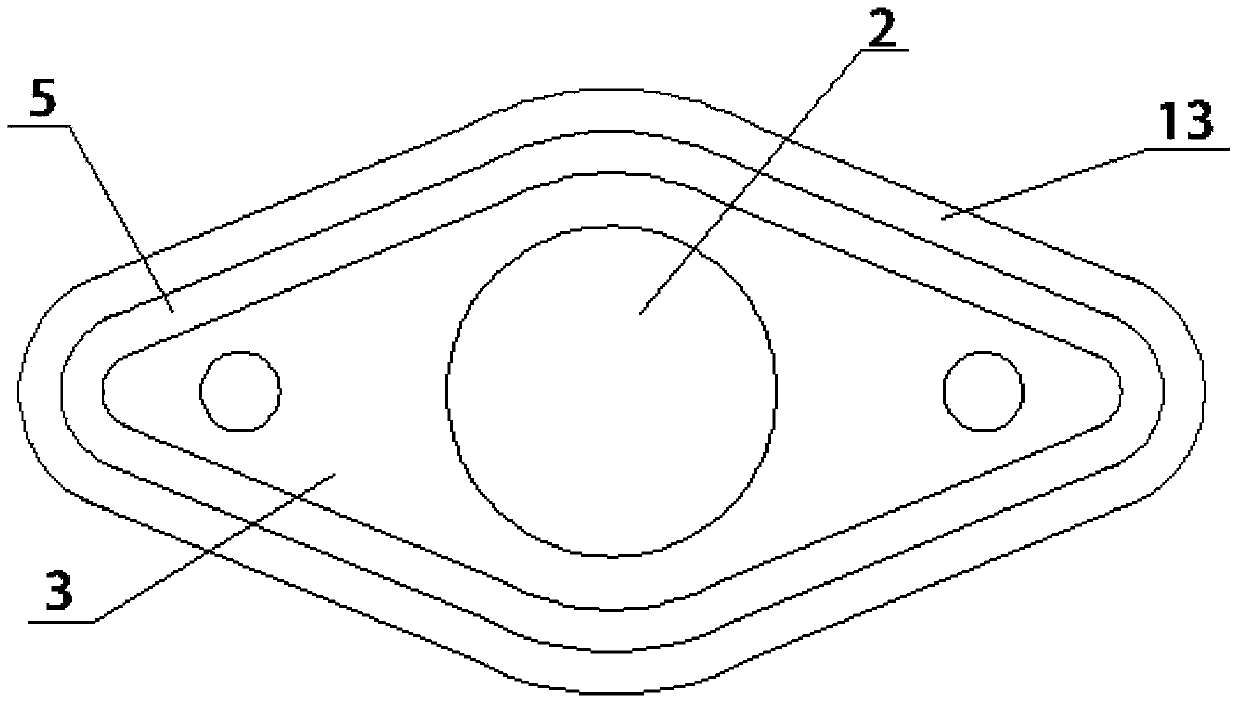

[0015] Such as figure 1 and figure 2 A coreless air pressure heat preservation pouring furnace is shown, its structure includes a crucible 2, a furnace lining 3, a coil 5, a steel shell 13 and a sealed furnace cover 6, the crucible 2 is placed inside the furnace lining 3, and the left and right sides of the furnace lining 3 are respectively the feed flow Groove 8 and discharge launder 9; a siphon tube 4 is formed between the crucible 2 and the furnace lining 3, the coil 5 surrounds the outside of the furnace lining 3, the steel shell 13 is installed on the outside of the coil 5, and a gas inlet 7 is provided on the side of the crucible 2 . When working, the coil 5 generates a magnetic field by passing current to the coil 5, and the metal placed in the magnetic field will continue to heat up under the action of the induced eddy current, and at the same time, the pressurized gas is passed into the crucible 2 through the gas inlet 7 to increase the temperature ( Insulation) mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com