Double spring support pull type automatic filling valve float valve

An automatic grouting, double-spring technology, applied in wellbore/well components, earthwork drilling, flushing wellbore, etc., can solve the problems of incapable of automatic grouting torsion spring, easily damaged float valve, failure, etc. Blowout, time saving, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

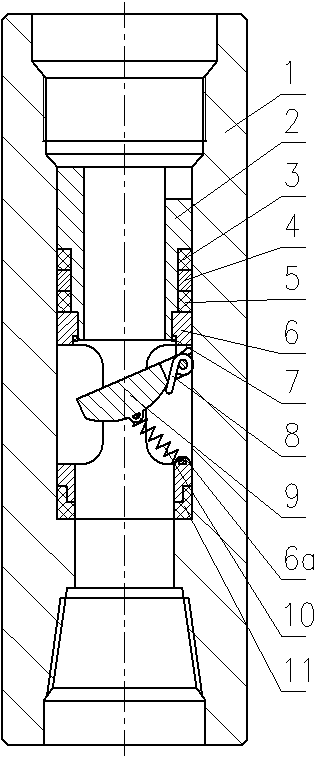

[0011] Such as figure 1 As shown, a double-spring support type automatic grouting valve float valve is composed of a float valve joint 1, a float valve and a valve support device. The float valve consists of an upper valve body 2, an upper sealing ring 3, a sealing gasket ring 4, a middle The sealing ring 5, the valve body seat 6, the valve sealing ring 7, the valve 9 and the lower sealing ring 11 are composed of the valve supporting device, which is composed of the valve supporting spring hook 6a, the support torsion spring 8 and the supporting spring 10, and the floating valve Placed in the float valve joint 1, the upper valve body 2 is connected with the valve body seat 6 with threads, the upper sealing ring 3, the gasket ring 4, and the middle sealing ring 5 are set on the upper valve body 2, and the valve sealing ring 7 is inlaid Installed in the groove of the valve body seat 6 at the closing position of the valve 9, the lower sealing ring 11 is set on the lower end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com