Subframe-free glass face material for curtain walls

A glass surface, sub-frame-free technology, applied in building components, windows/doors, buildings, etc., can solve the problems affecting the safety and life of glass curtain walls, easy failure of structural sealants, and cumbersome assembly procedures, saving logistics and manpower. Cost, improvement of gluing process requirements and use environment requirements, the effect of easy on-site operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

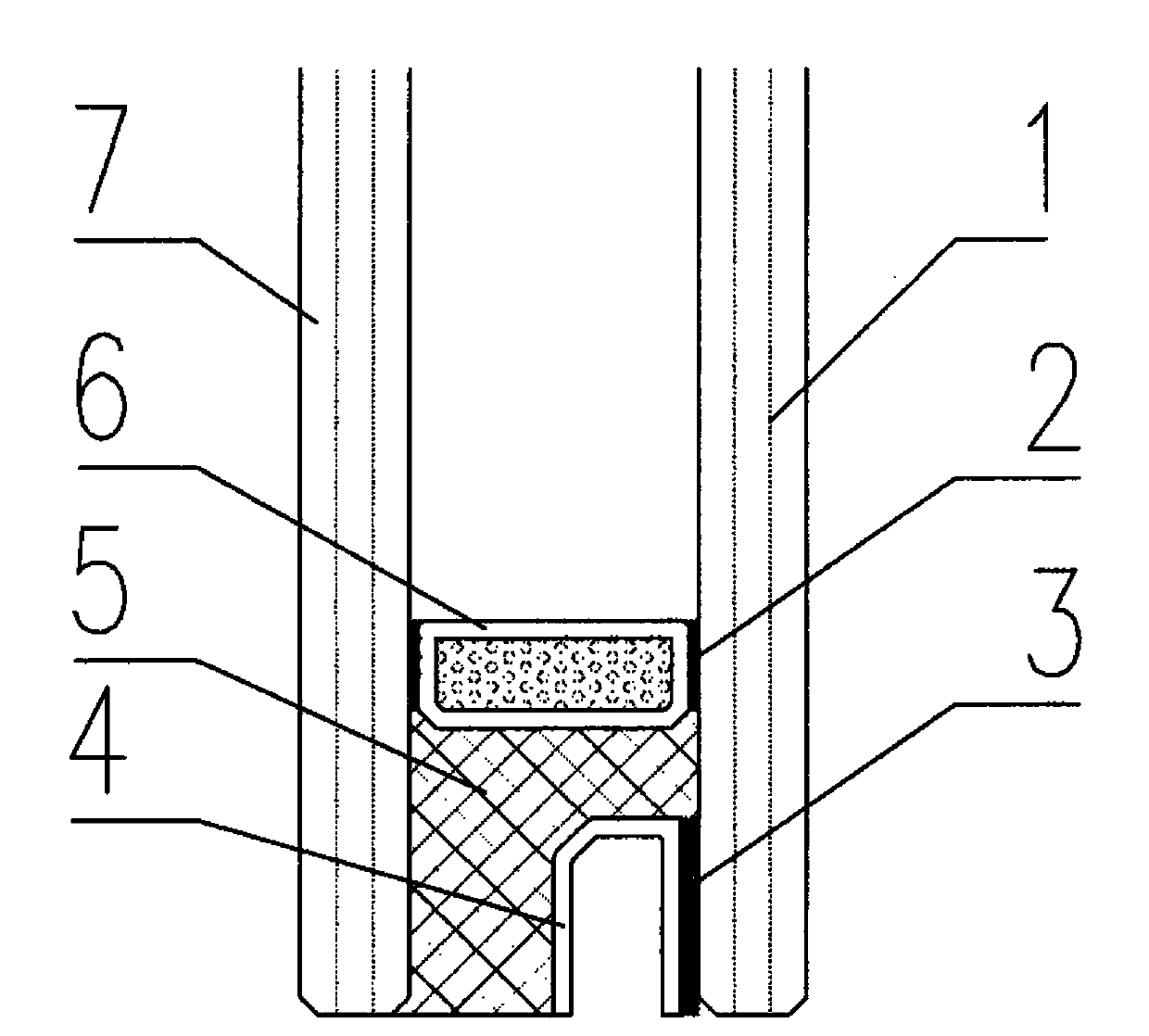

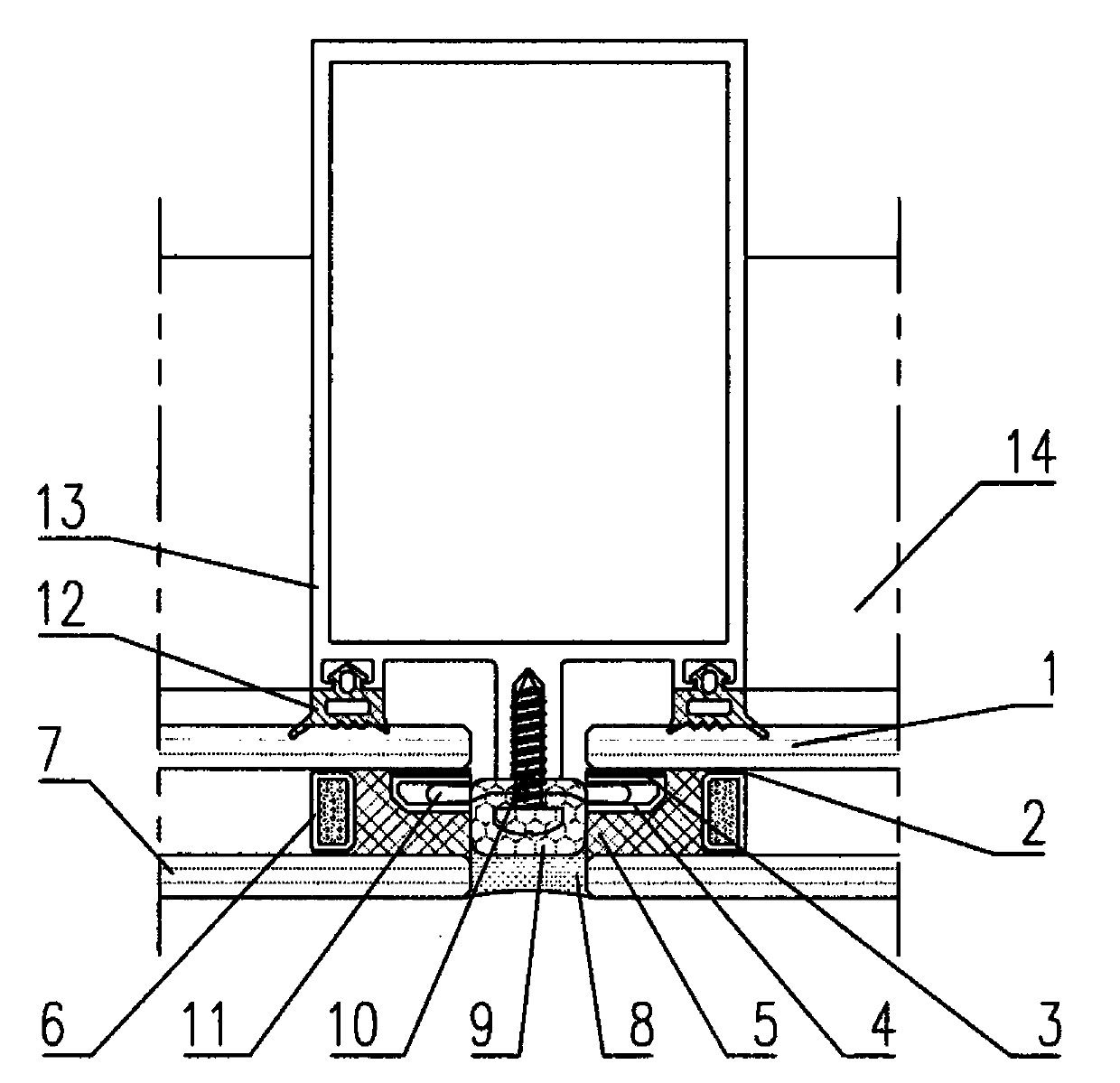

[0013] according to Figure 1~2 The specific structure of the present invention will be described in detail. The sub-frame-free glass surface material for the curtain wall includes an inner glass 1, an outer glass 7, a spacer 6 fixed between the inner and outer glass 1 and 7, a structural sealant 5, and an adapter 4 And by screws 10, two adjacent glass surface materials are fixed on the main frame of the curtain wall, and the pressing plate and other parts inserted in the opening groove of the adapter piece 4 are inserted. Wherein the main frame of the curtain wall is composed of commonly used curtain wall mullions 13 and curtain wall transverse frames 14 . The inner glass 1, the outer glass 7, the spacer 6 with a built-in desiccant and the air-insulating sealant 2 are combined according to the conventional hollow glass processing technology. The adapter piece 4 adopts a profile structure with an "n" shape in cross section. The adapter piece 4 needs to be glued to the contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com