Architectural ceramic thin plate curtain wall dry hanging structure and construction method thereof

A technology of architectural ceramics and implementation methods, which is applied in the direction of building components, building structures, buildings, etc., can solve the problems of not conforming to the modern concept of green buildings, poor seismic performance, and generation of dusty construction waste, etc., to achieve small deformation coefficient and bending resistance The effect of good strength, good thermal insulation and fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

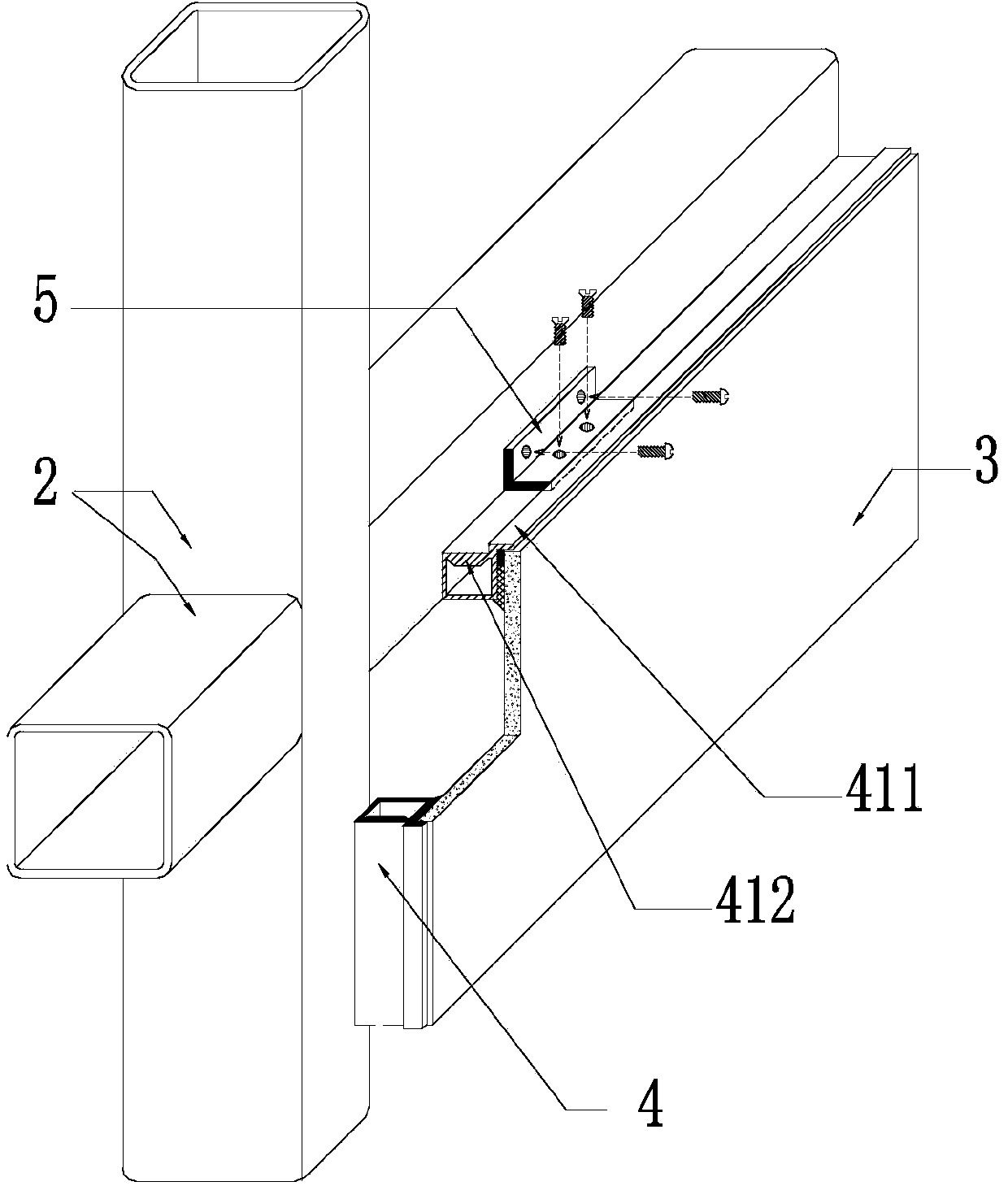

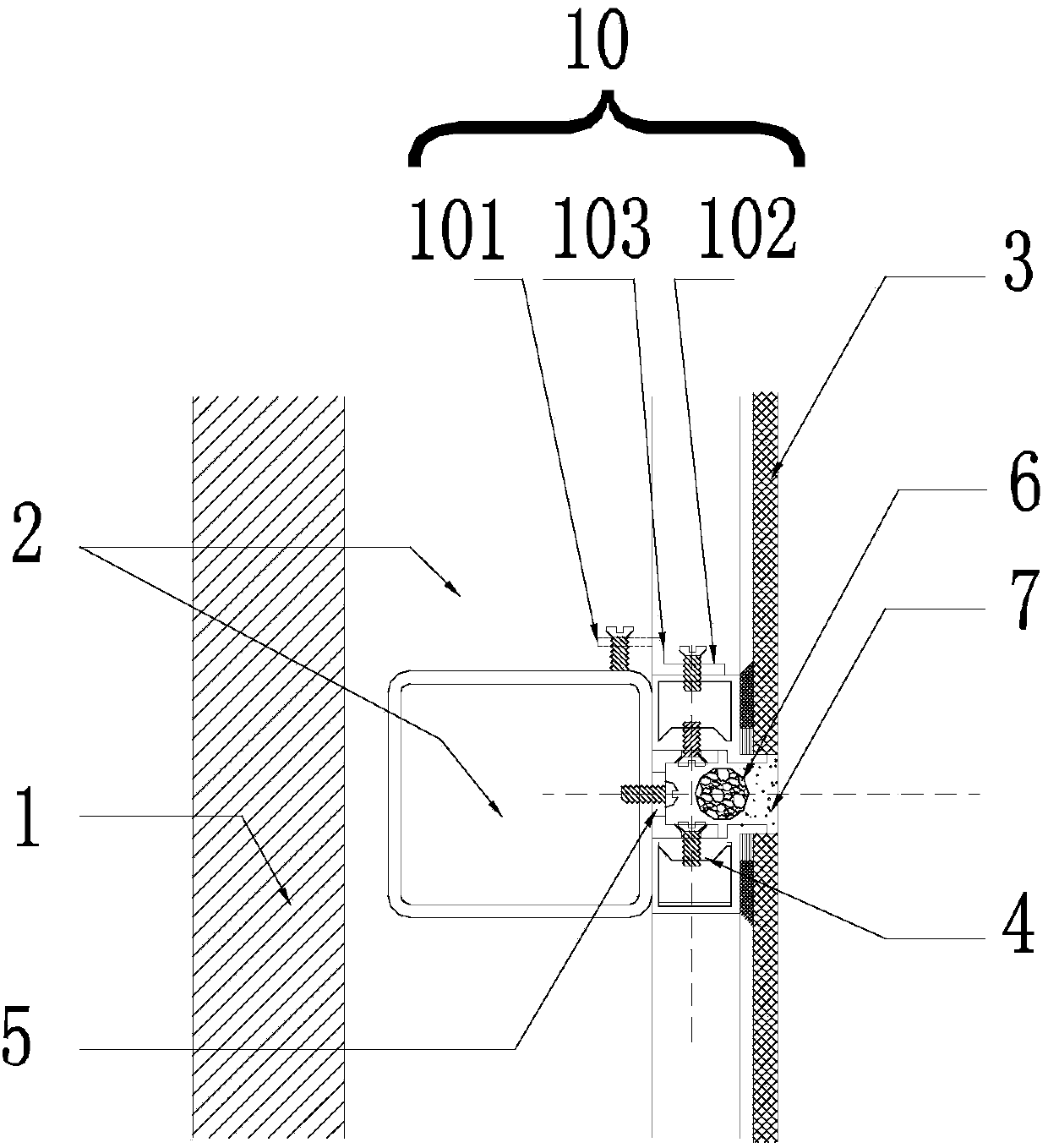

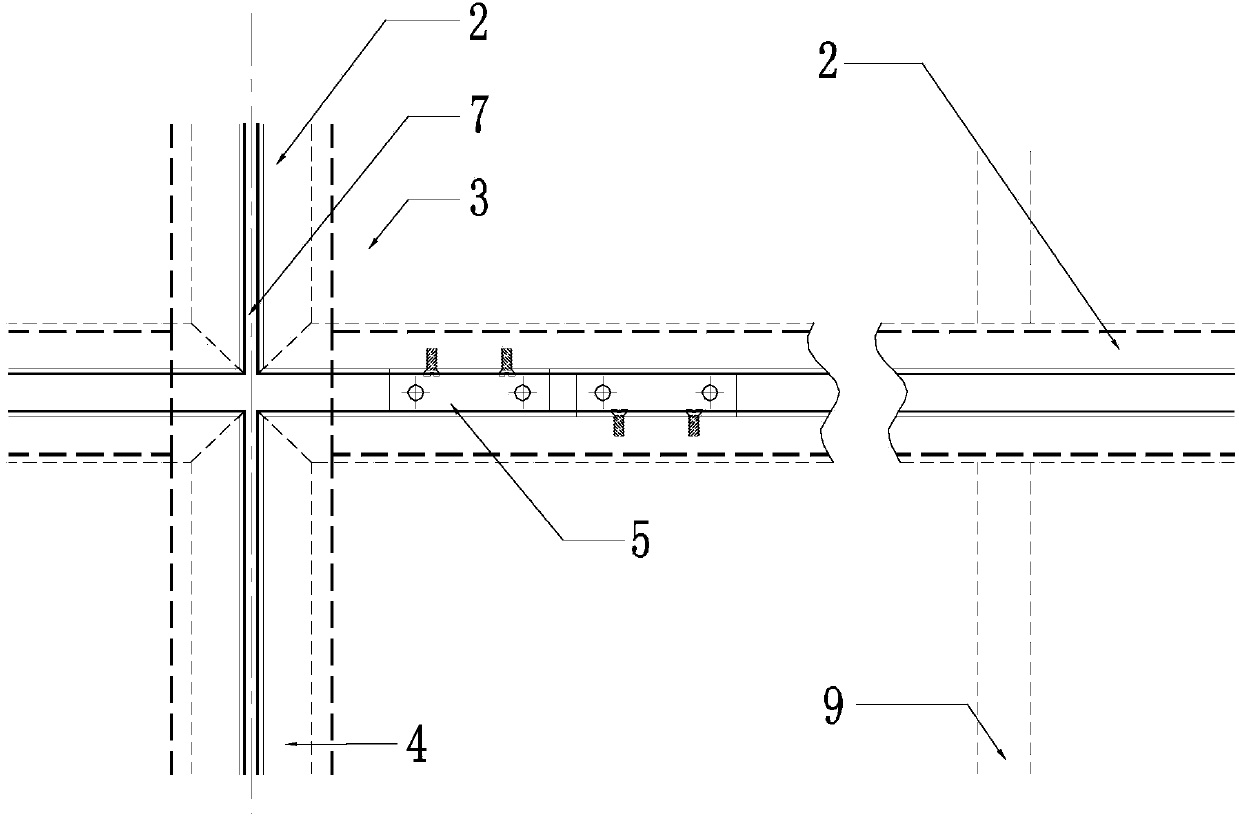

[0045] Such as Figure 1 to Figure 5 As shown, the dry-hanging structure of building ceramic sheet curtain wall includes wall 1, keel 2, building ceramic sheet 3, connecting component 4, corner code 5, thermal insulation filling material 6, caulking glue 7 and epoxy glue composite glass fiber mesh 8 ;

[0046] The keel 2 is vertically and horizontally intersected and installed on the wall 1 to form a square frame structure. The size of the square frame formed by the keel 2 is matched with the building ceramic sheet 3, and one square frame Installing a thin building ceramic plate 3;

[0047] Such as figure 1As shown, the connection assembly 4 is fixed on the back of the building ceramic sheet 3 along the edge of the building ceramic sheet 3, and the connection assembly 4 is fixed on the keel 2 by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Section diameter | aaaaa | aaaaa |

| Torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com