Modular unit combined prefabricated wallboard

A prefabricated wall panel and modular technology, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems of non-insulation of walls, affecting the appearance of walls, and damage of wall products, and achieves good thermal insulation and fire prevention effects, Easy to discharge lines, fast and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

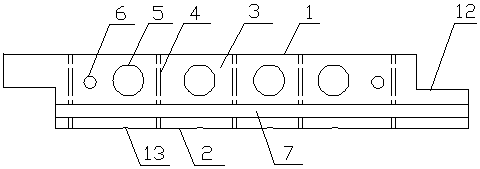

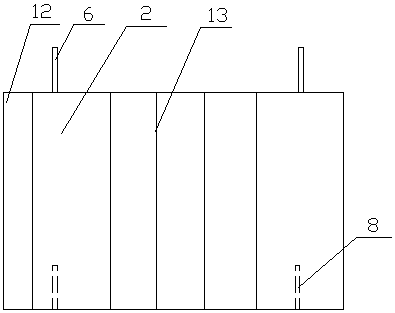

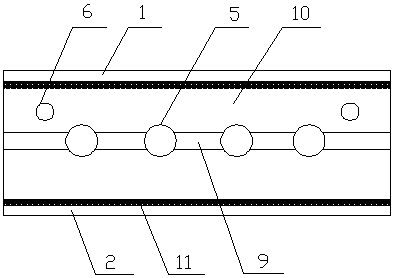

[0021] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

[0022] As shown in the figure, a modular unit combined prefabricated wallboard according to the present invention has a vertical through hole 5 in the base body, which can reduce the weight of the wallboard, and can also be used as a channel for wire pipes. There are vertical direction marks 13, and the marks correspond to the positions of the through holes 5. When electricity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com