Construction method of installation equipment without sizing block

A construction method and a technology for installing equipment, which are applied in the construction field without shim iron installation equipment, can solve the problems of low leveling accuracy, difficulty, and slow leveling speed, and achieve high leveling accuracy and fast leveling speed , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

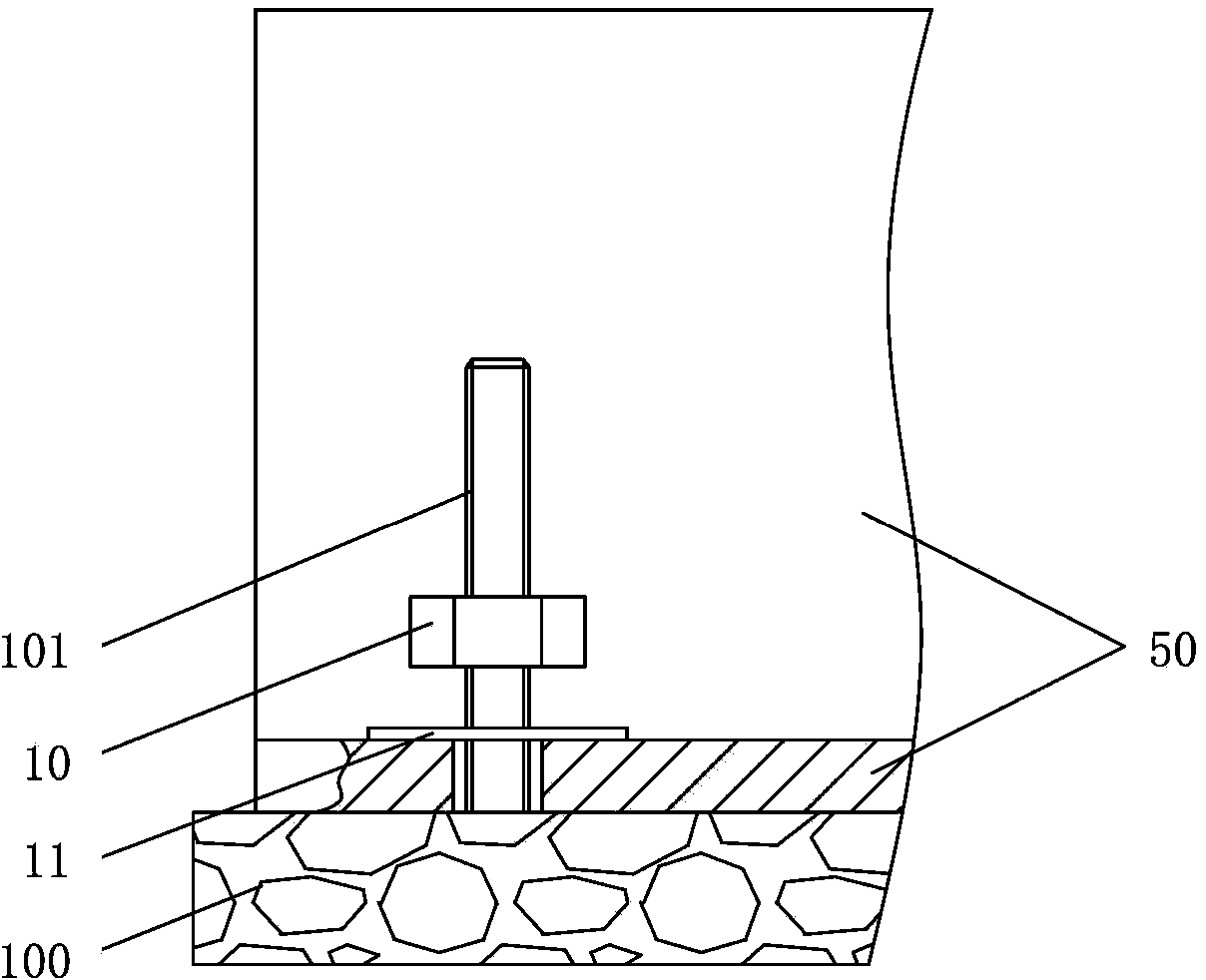

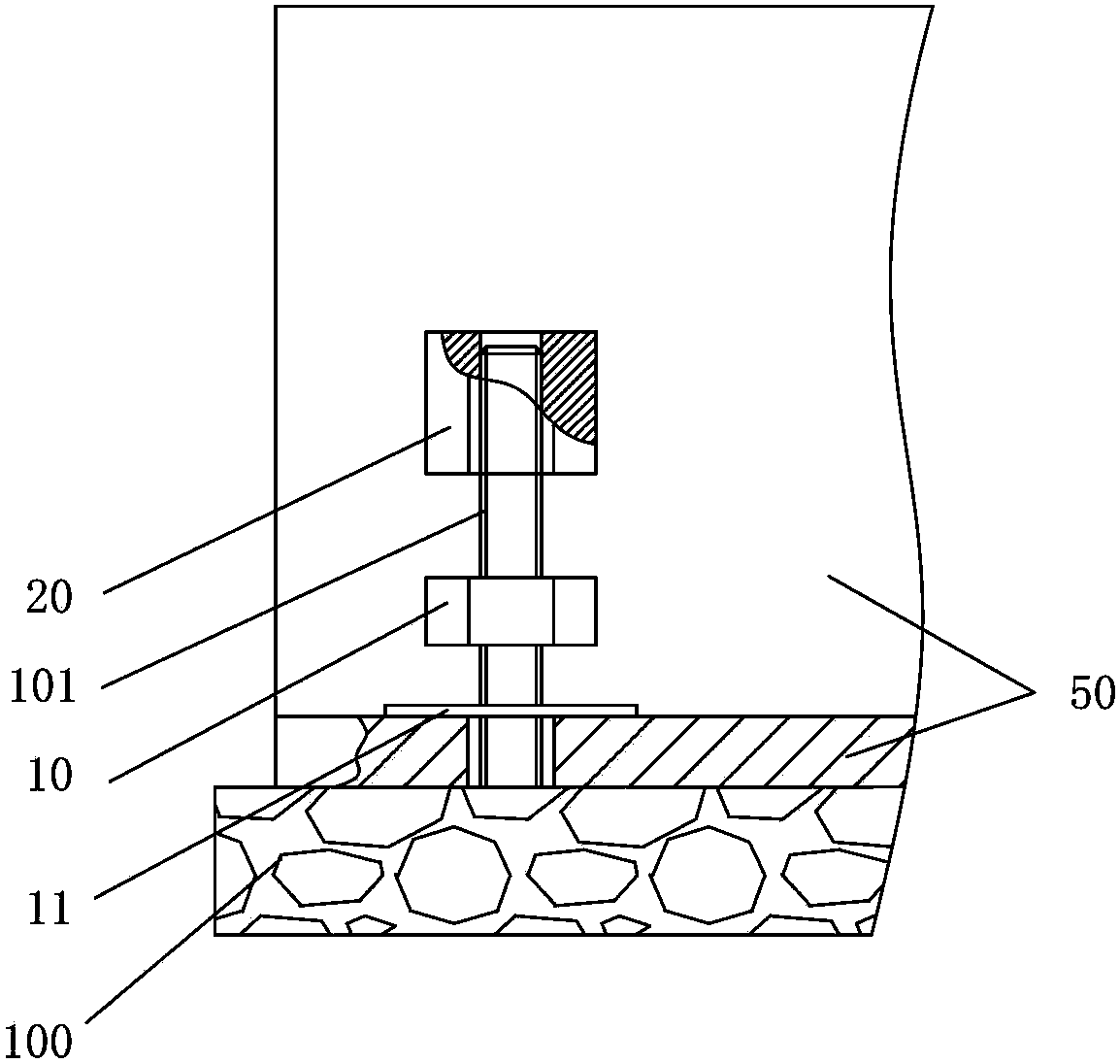

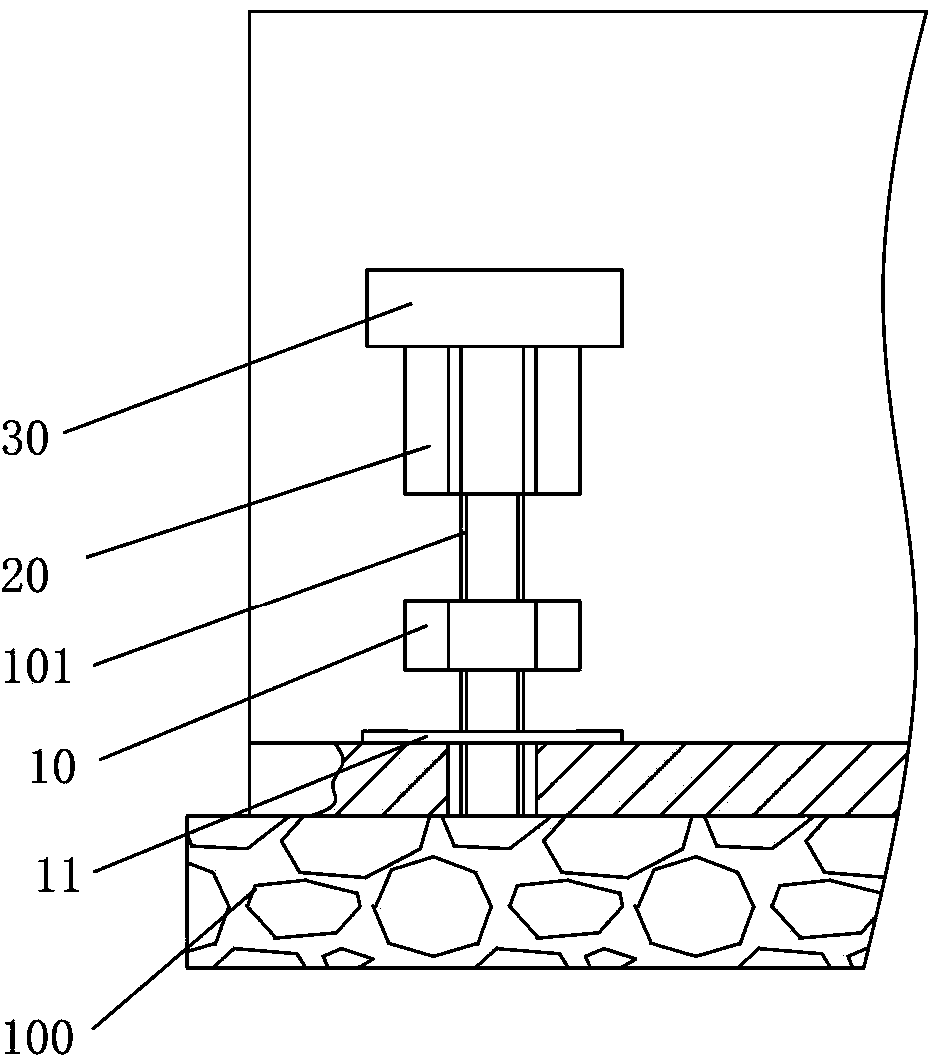

[0015] Figure 1 to Figure 4 is a process diagram showing a construction method of a shimless installation device according to an embodiment of the present invention.

[0016] Such as figure 1 As shown, first, according to the construction blueprint and related specifications, the installation foundation 100 of the pouring equipment needs to be installed while the foundation 100 is being poured. The installation dimensions and relative positions of the anchor bolts 101 should be accurate so as not to affect subsequent construction. When checking and accepting the foundation 100, the size of the anchor bolts, installation requirements, and positioning dimensions should be strictly checked.

[0017] After the foundation 100 is checked and accepted, the base 50 of the equipment is directly installed on the anchor bolts 101 . During the hoisting process of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com