Self-traveling type intelligent continuous dynamic compactor

A dynamic tamping machine and self-propelled technology, which is applied in the field of foundation soil survey, soil protection, construction, etc., can solve the problems of large influence on the surrounding structure, poor off-road performance and stability of the loader, and time-consuming problems, and achieve the tamping depth It has the effect of large impact depth, good off-road performance and stability, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

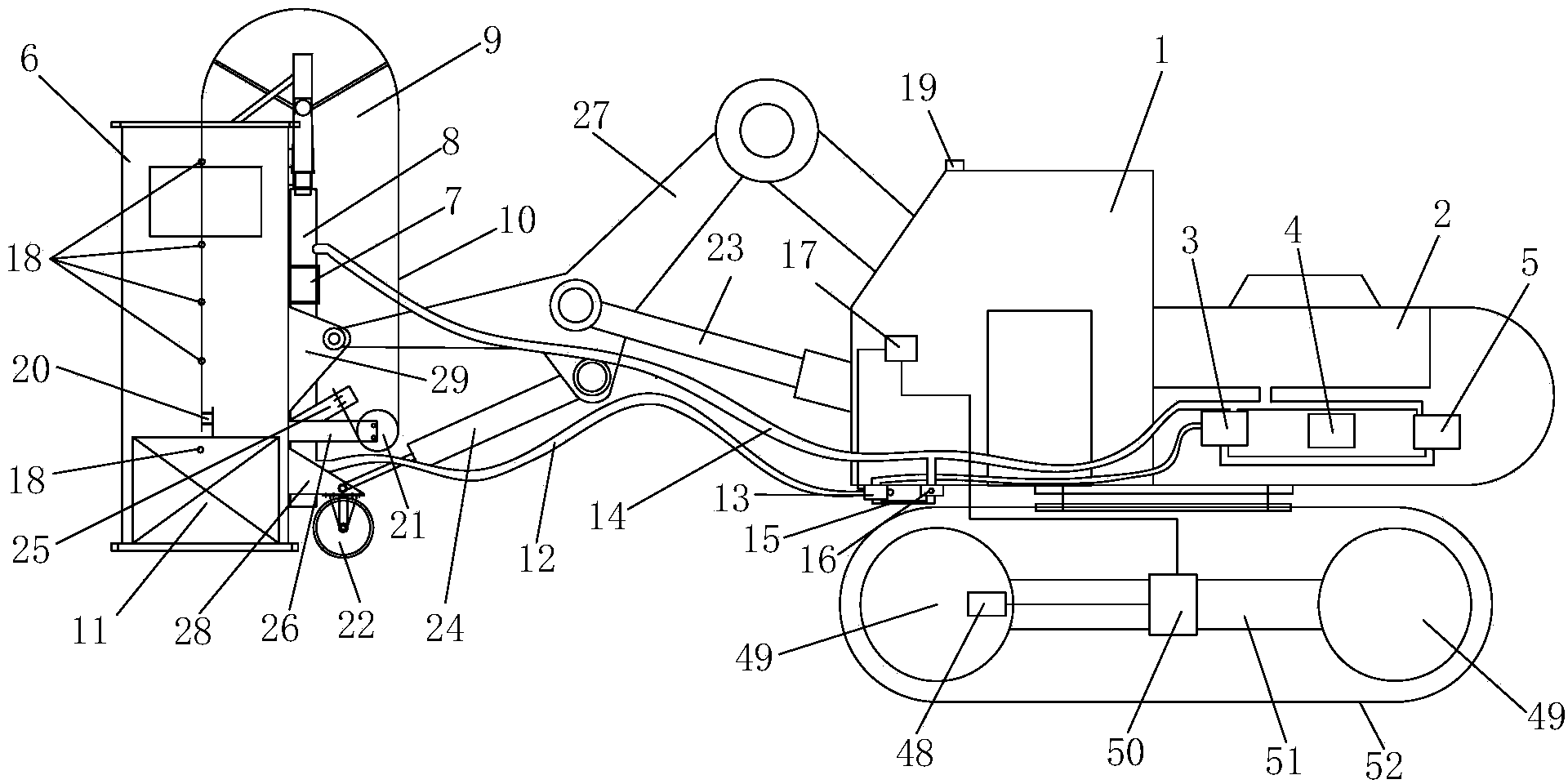

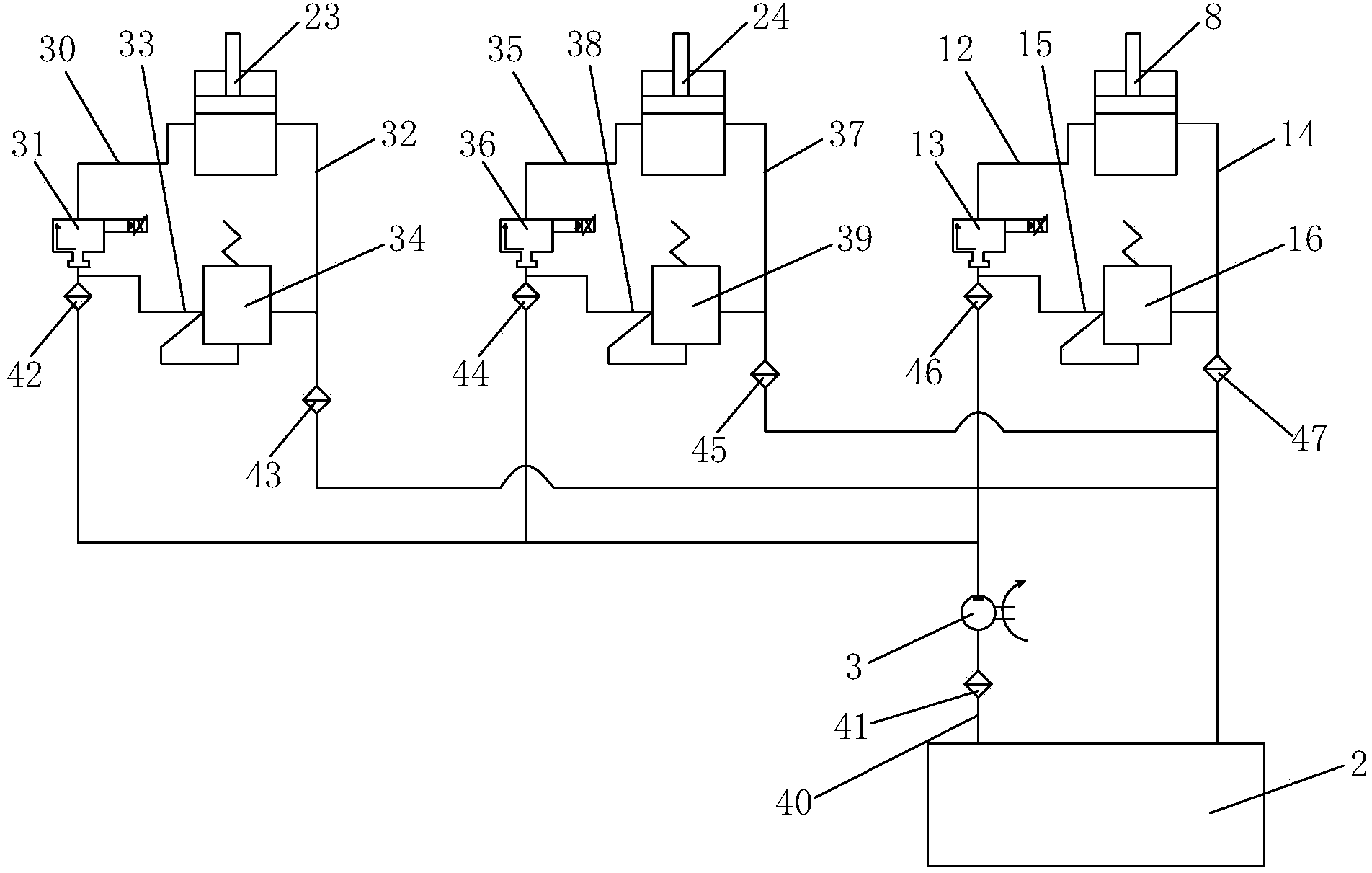

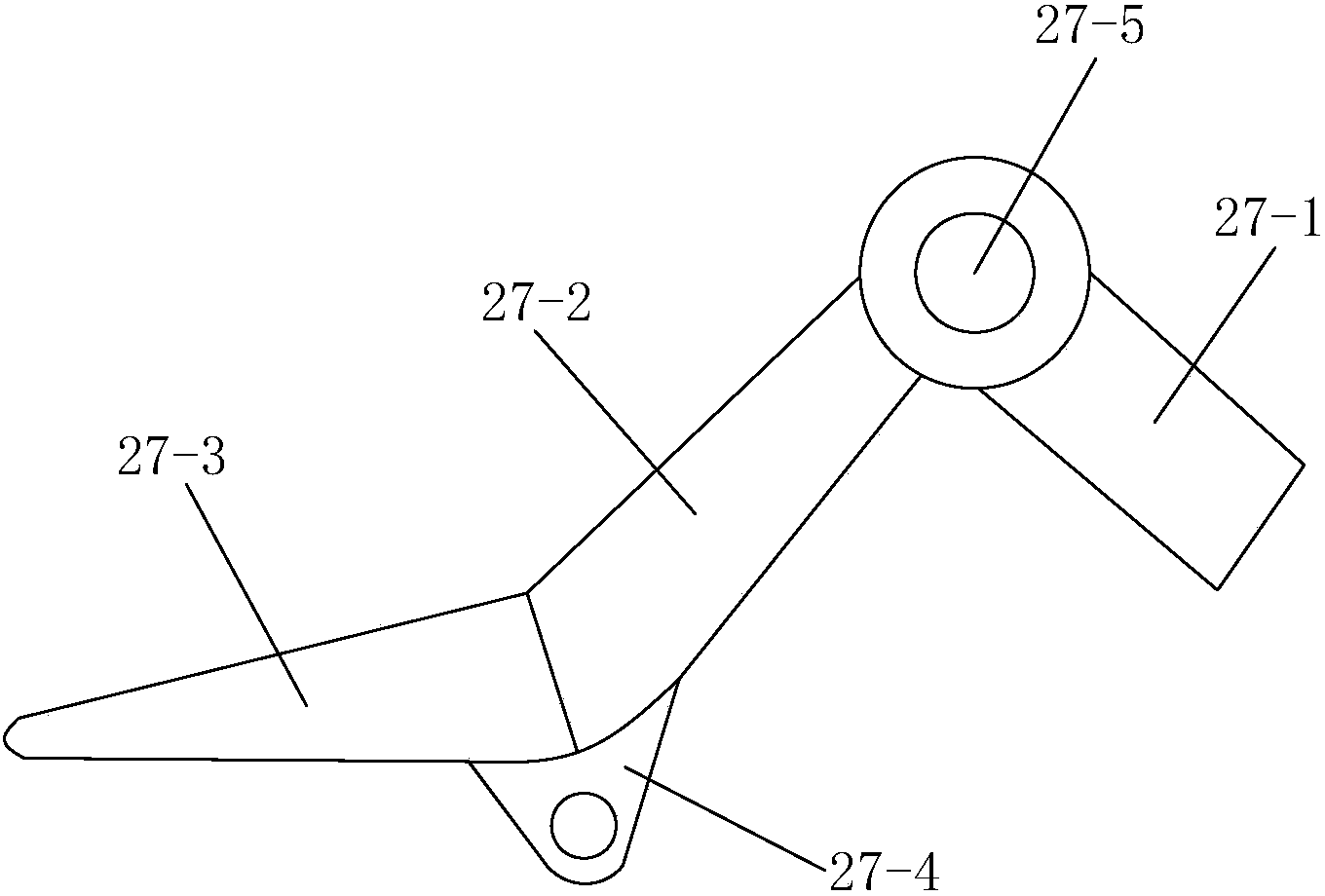

[0062] like figure 1 As shown, the present invention includes a crawler excavator 1, a crawler excavator power system and a crawler excavator self-propelled mechanism, and is connected to the crawler excavator 1 through a connecting arm 27, a first oil cylinder 23 and a second oil cylinder 24 The tamping mechanism of the crawler excavator; the crawler excavator power system includes a fuel tank 2, an oil pump 3 and a radiator 4 connected to the fuel tank 2, and an engine 5 connected to the oil pump 3; the crawler excavator self-propelled mechanism includes a walking frame 51 , the walking wheel 49 that is connected on the walking frame 51 and the walking track 52 that is connected on the walking wheel 49, and the self-propelled control system that is used to control the self-propelling of the walking wheel 49 and the walking track 52; the compacting mechanism includes Frame 6, the oil cylinder fixing flange 7 that is connected on the frame 6 and the 3rd oil cylinder 8 that is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com