Crystal growth device

A long crystal and hemispherical technology, applied in the field of iron and steel metallurgy, can solve the problems of inability to meet the basic requirements of the beneficiation process, low selectivity, and hindered migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the embodiments. However, the following embodiments are only used for illustrative purposes and cannot be used to limit the present invention. The same symbols in the various drawings always represent the same elements.

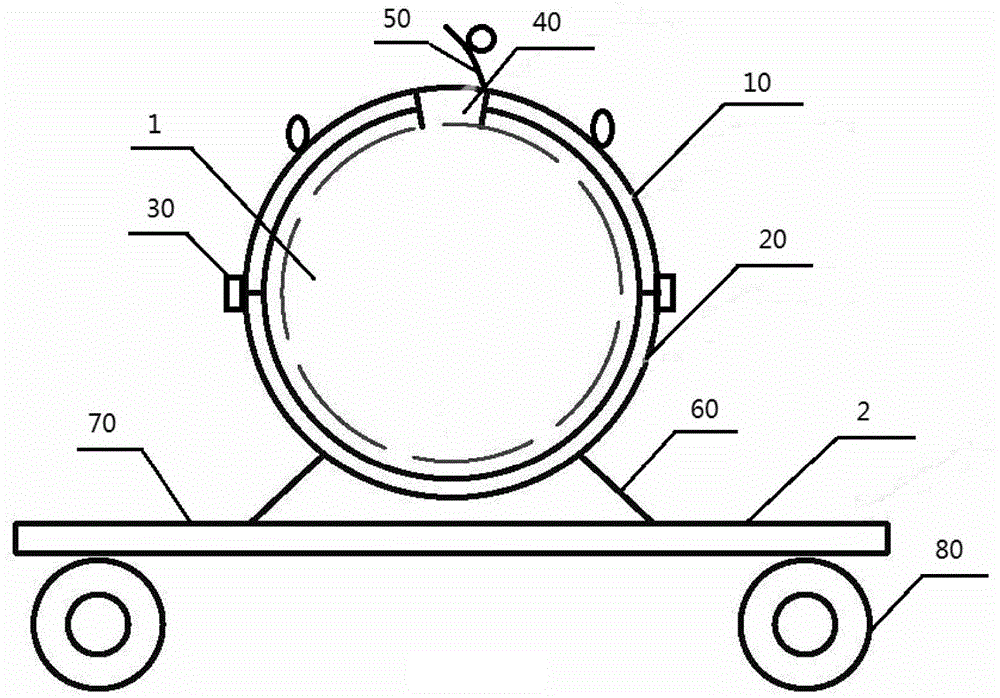

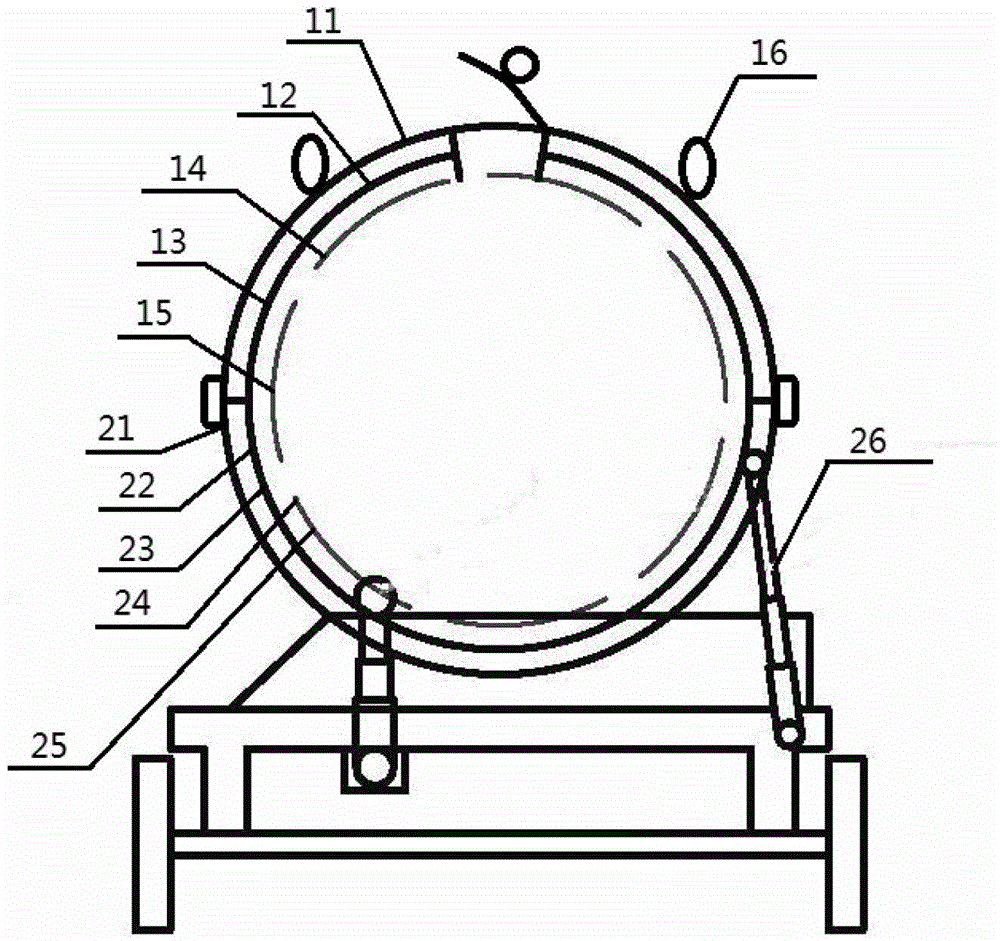

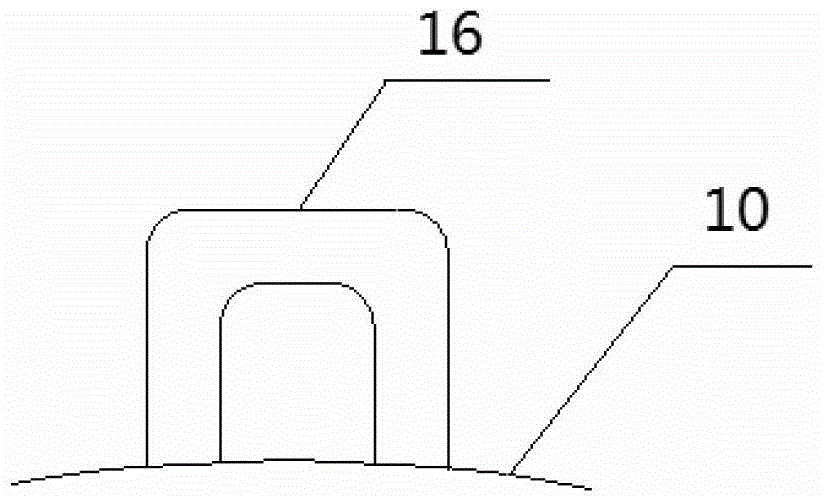

[0033] According to the three transfer principles of heat energy: heat conduction, heat radiation and heat convection, the present invention designs a spherical heat preservation crystal growth device, which comprehensively slows down the cooling speed of the molten slag after it is released from the furnace, and can make the crystal grains in the molten slag grow longer. As large as the particle size meets the requirements of mineral processing, it also lays a theoretical foundation for the subsequent establishment of a mathematical model for the cooling of slag balls and the crystal growth process.

[0034] The present invention will be discussed in detail below by taking the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com