Steam distillation aromatic essential oil device

A technology of steam distillation and aromatic essential oils, which is applied in the direction of essential oils/fragrances, fat production, etc., which can solve the problems of reduced oil yield, insufficient soaking, and inability to achieve uniform mixing of water and aromatic flowers, etc., to improve oil yield Efficiency, shortening the effect of distillation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

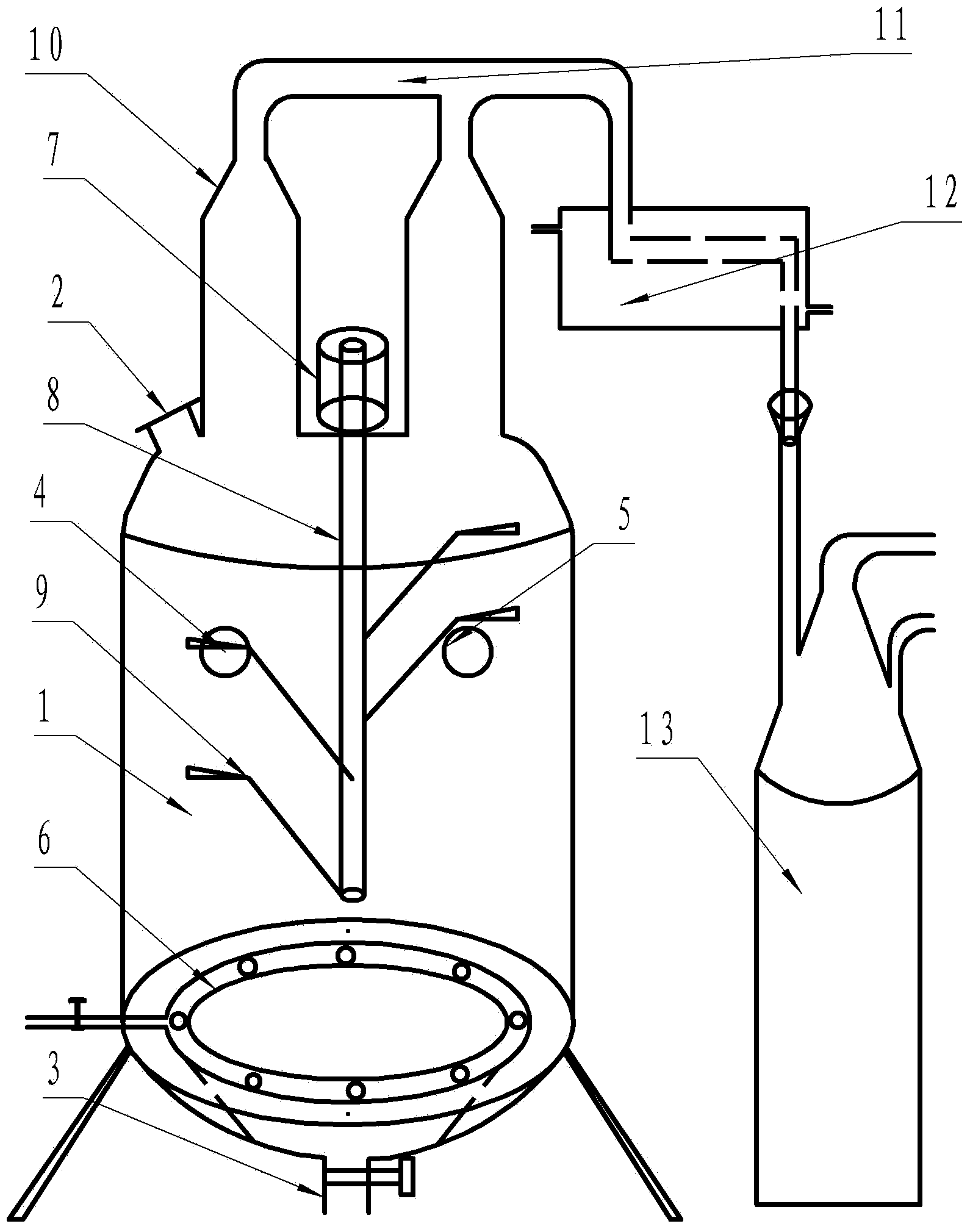

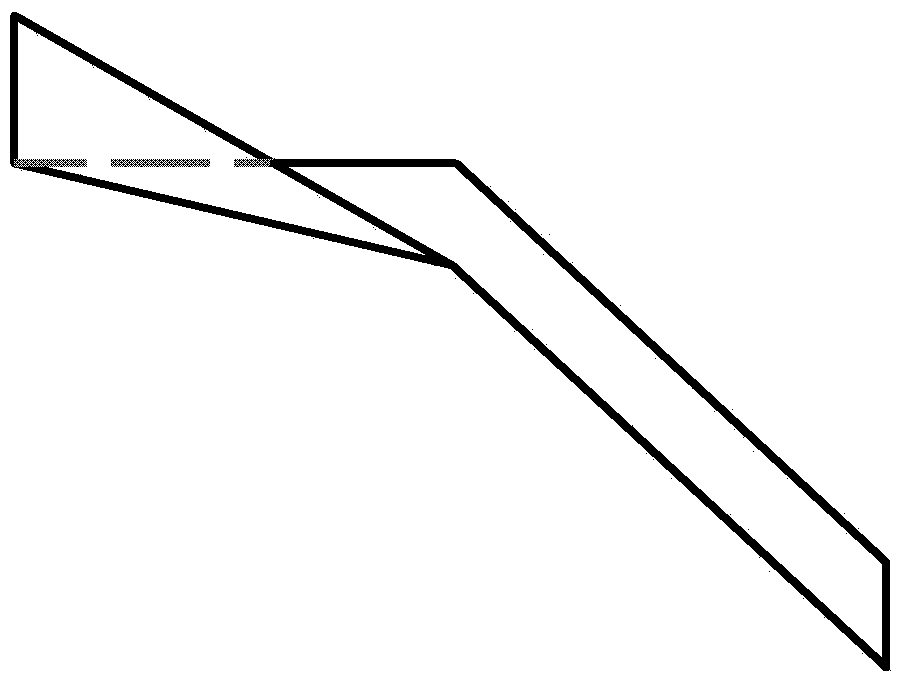

[0017] Embodiment 1, a device for steam distillation of aromatic essential oils, comprising a still 1, a double distillation column 10, a gooseneck 11, a cooler 12 and an oil-water separator 13, the top and the bottom of the still 1 are respectively arranged There is a feed port 2 and a discharge port 3. The bottom of the still body in the distillation still 1 is fixed with a steam coil 6 with a steam outlet connected to the liquid seal of the still body. Half part is provided with pressure gauge 4 and temperature gauge 5, it is characterized in that: the middle position between the re-distillation column 10 that described still 1 tank top is provided with is fixed with the agitating device 7 that has power plant, and described agitating The rotating shaft 8 of the device 7 is liquid-sealed and goes deep into the distillation still 1, and the rotating shaft 8 deep into the still 1 is spirally fixed with strip-shaped stirring blades 9 in turn.

[0018] The length of the rotatin...

Embodiment 2

[0025] Embodiment 2, a steam distillation device for aromatic essential oils, comprising a still 1, a double distillation column 10, a gooseneck 11, a cooler 12 and an oil-water separator 13, the top and the bottom of the still 1 are respectively arranged There is a feed port 2 and a discharge port 3. The bottom of the still body in the distillation still 1 is fixed with a steam coil 6 with a steam outlet that is sealed with the still liquid. The half of the still body of the still 1 is The part is provided with pressure gauge 4 and thermometer 5, and it is characterized in that: the intermediate position between the double distillation column 10 that described distillation kettle 1 tank top is provided with is fixed with the stirring device 7 that has power plant, and described stirring device The rotating shaft 8 of 7 is liquid-sealed and goes deep into the still 1, and the rotating shaft 8 that goes deep into the still 1 is spirally fixed with strip-shaped stirring blades 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com