Steam distillation aromatic essential oil equipment

A technology for steam distillation and aromatic essential oils, which is applied in the directions of essential oils/spices, fat generation, etc., can solve the problems of affecting the aroma quality of aromatic essential oils, reducing the oil yield of aromatic flowers, aggravating the non-uniformity of distillation, etc. Paste, improve oil yield, shorten the effect of distillation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

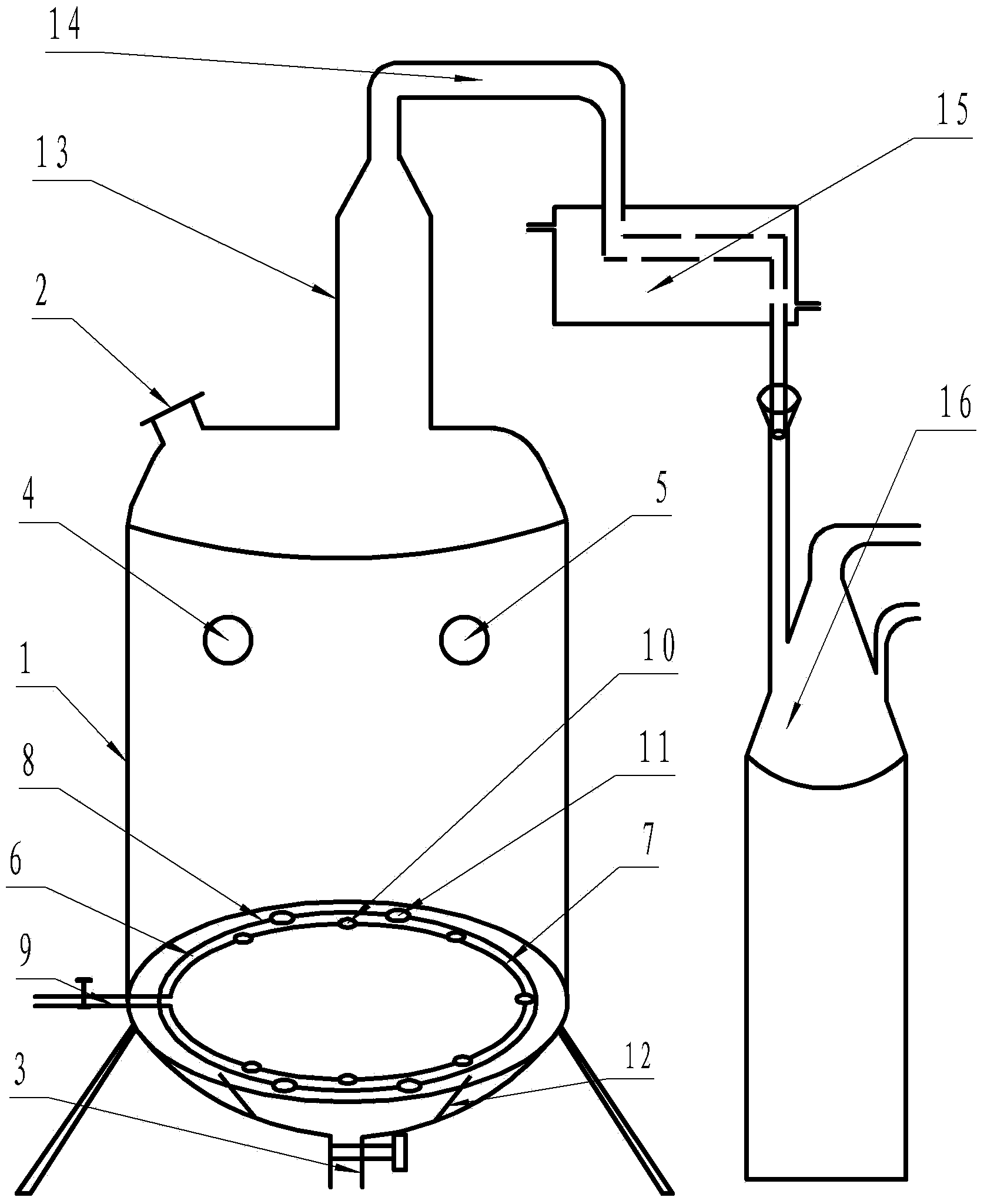

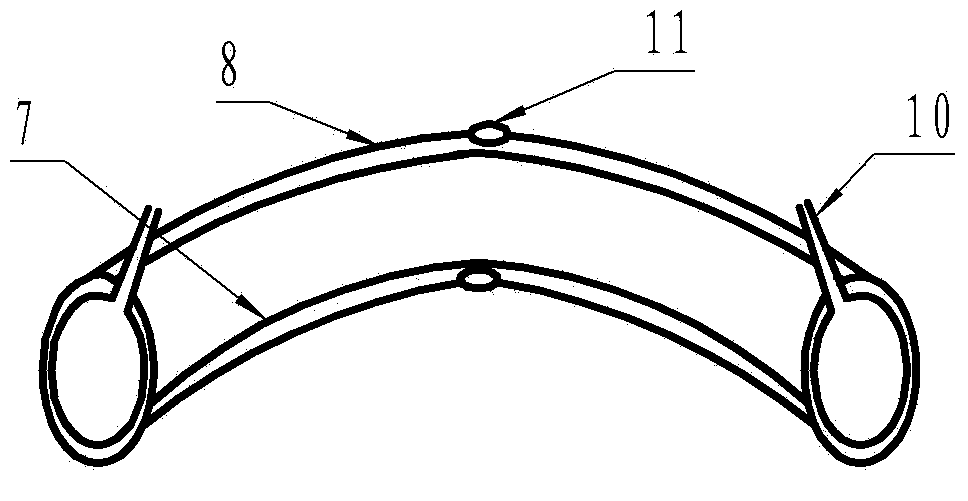

[0016] Embodiment 1, a kind of steam distillation aromatic essential oil equipment, comprises distillation still 1, double distillation column 13, gooseneck 14, cooler 15 and oil-water separator 16, the still top and still bottom of described still 1 are respectively arranged There is a feed port 2 and a discharge port 3, and the upper part of the kettle body is provided with a pressure gauge 4 and a temperature gauge 5, and it is characterized in that: the bottom of the still body of the still 1 is horizontally fixed with a double-layer hollow steam coil 6. The inner pipe 7 of the double-layer hollow steam coil 6 is liquid-sealed and connected to the steam outlet pipe 10 connected thereto, and the steam outlet pipe 10 is liquid-sealed and passes through the outer pipe 8 of the steam coil 6 to form a ring distribution, the inner wall of the inner tube 7 on one side of the double-layer hollow steam coil 6 is liquid-tightly connected to the outer tube 8 passing through the steam ...

Embodiment 2

[0021] Embodiment 2, a kind of steam distillation aromatic essential oil equipment, comprises distillation still 1, double distillation column 13, gooseneck 14, cooler 15 and oil-water separator 16, the still top and still bottom of described still 1 are respectively set There is a feed port 2 and a discharge port 3, and the upper part of the kettle body is provided with a pressure gauge 4 and a temperature gauge 5, and it is characterized in that: the bottom of the still body of the still 1 is horizontally fixed with a double-layer hollow steam coil 6. The inner pipe 7 of the double-layer hollow steam coil 6 is liquid-tightly connected to the steam outlet pipe 10 communicating with it, and the steam outlet pipe 10 is liquid-tightly passed through the outer pipe of the double-layer hollow steam coil 6 8 is distributed in a ring shape, and the inner wall of the inner tube 7 on one side of the double-layer hollow steam coil 6 is liquid-tightly connected to the outer tube 8 commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com