Red bayberry extract for tobacco, its preparation method and its use as tobacco additive

A bayberry drying technology, applied in tobacco, tobacco treatment, application, etc., can solve the problems of less research on deep processing and poor fruit quality, and achieve stable cigarette quality, increase softness, increase smoke concentration and aroma Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The research of the preparation of red bayberry extract for embodiment 1 tobacco

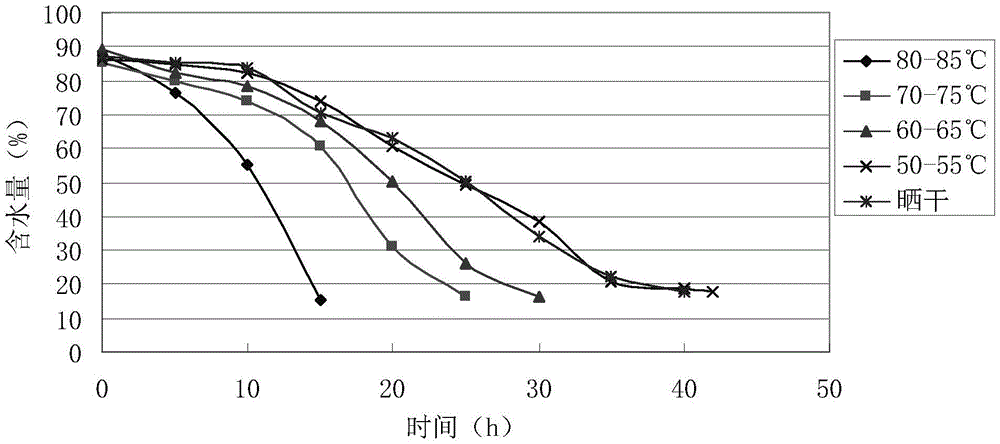

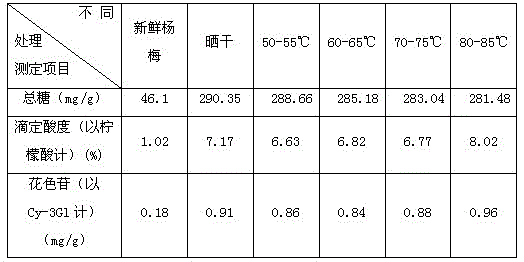

[0027] 1. Effects of different baking temperatures on the main nutritional components of bayberry

[0028] The experiment adopts natural drying, 50-55°C, 60-65°C, 70-75°C or 80-85°C baking. During the baking process, the bayberry is turned intermittently to ensure that the bayberry is heated evenly. Sampling is taken to measure its moisture content, and the drying is stopped when the moisture content reaches 10-20%, and the total sugar, titrated acidity and anthocyanins are measured. The determination method is as follows:

[0029] Determination of total sugar content: phenol sulfuric acid method.

[0030] Determination of total acid content: using acid-base titration method.

[0031] Determination of anthocyanin content: Utilizing the structural characteristics of anthocyanins has a maximum absorption peak at 520nm when the pH is 1.0, and when the pH is 4.5, anthocyanins transform int...

Embodiment 2

[0059] The experiment adopts natural drying or drying at 80-85°C. During the sun-drying or baking process, the bayberry is turned intermittently to ensure that the bayberry is heated evenly. Samples are taken at regular intervals to measure its moisture content. The time for 20% moisture content is stopped, and the open ventilation alcoholization is carried out at a temperature of 20-25°C and a humidity of 50-60%, and the time is 1-3 months.

[0060] After the alcoholization, the dried red bayberry is pitted and weighed to take a certain weight. After grinding and pulverizing, use the water extraction method with a solid-liquid ratio of 1:10-20. The extraction time is 1-2h, and the extraction times are 2 times. Combine the extracts, and extract the extracts Concentrate in vacuum on a rotary evaporator, the concentration temperature is 45-55 ° C, concentrate until viscous, collect the extract, and store in a sealed low temperature.

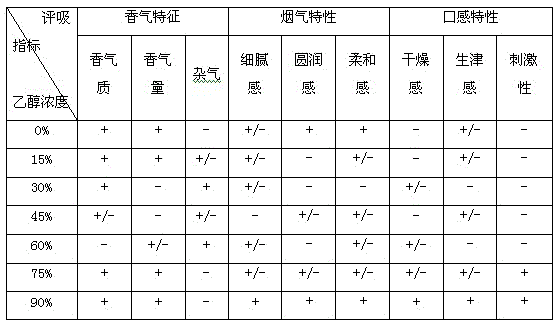

[0061] Take 0.5g of red bayberry extract, di...

Embodiment 3

[0063] Adopt the method among the embodiment 2, adopt 90% ethanol to extract and obtain red bayberry extract, red bayberry extract is diluted and sprayed on shredded tobacco, makes cigarette, and the result of smoking is that fragrance is made fuller, and miscellaneous gas reduces, and smoke has been improved characteristics, making the smoke more mellow and soft, and the aftertaste more pure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com