Blast furnace coal injection combustion improver as well as application and device thereof

A technology of blast furnace coal injection and combustion accelerant, which is applied in the field of iron and steel metallurgy, can solve the problems of large amount of catalyst addition, corrosion and shortage of blast furnace equipment and gas pipelines, etc., to improve the quality and output of molten iron, increase the production capacity of the blast furnace, and achieve huge economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

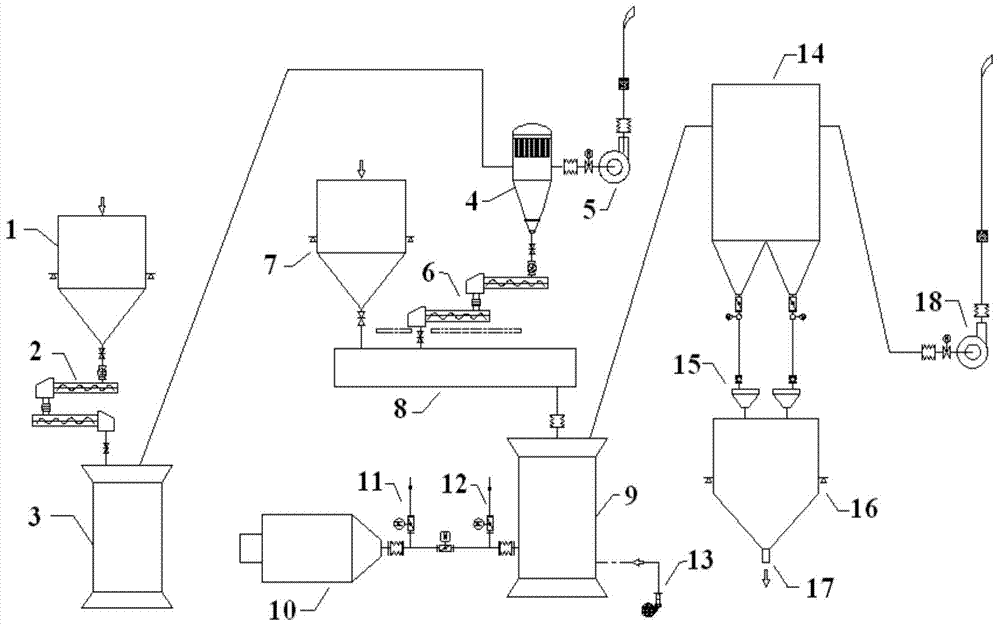

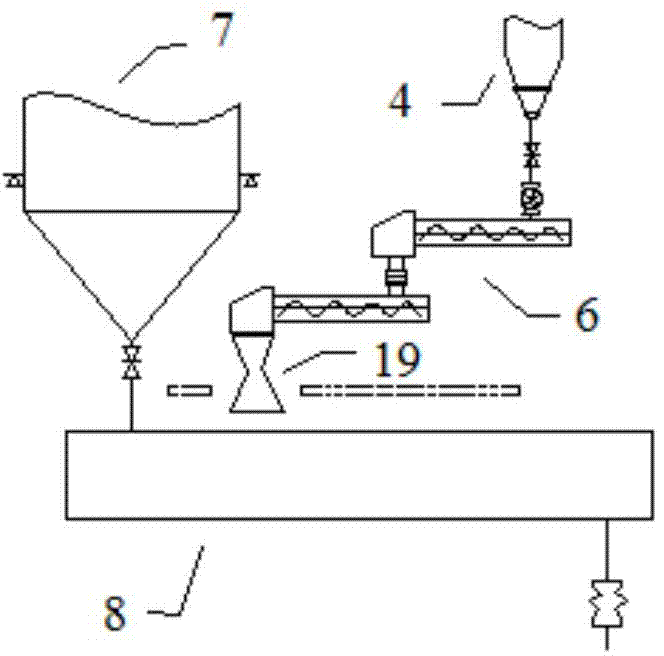

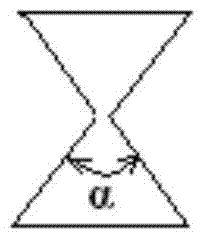

[0059] A blast furnace coal injection device, such as Figure 1-3 Shown: combustion aid raw material bin 1, screw feeder 2, ultrafine mill 3, combustion aid storage tank 4, combustion aid storage tank 4 is equipped with a second exhaust fan 5, screw metering pump 6, raw coal bunker 7, airtight Weighing coal feeder 8, coal mill 9, powder collector 14, sawdust separator 15 and coal powder bin 16, a Laval pipe 19 is set at the outlet end of the screw metering pump, and a sealed fan 13 is set on the coal mill 9, and The first exhaust fan 18 is set on the powder collector 14, the heating furnace 10 is set on the coal mill 9, the coal grinding machine 9 is connected with the heating furnace 10 through a pipeline, and the release valve 11 and the cold air valve 12 are arranged in sequence on the pipeline; The diffraction angle α of the Val tube is 62°; the distance between the center line of the Laval tube 19 and the edge of the raw coal bunker 7 is 22 cm, and the Laval tube 19 is ar...

Embodiment 2

[0062] The blast furnace coal injection device is the same as that in Example 1, except that the diffraction angle α of the Laval tube is 52°; the distance between the center line of the Laval tube 19 and the edge of the raw coal bunker 7 is 31 cm.

Embodiment 3

[0064] The blast furnace coal injection device is the same as that of Example 1, except that the diffraction angle α of the Laval tube is 46°; the distance between the center line of the Laval tube 19 and the edge of the raw coal bunker 7 is 46 cm.

[0065] Method Example 1

[0066] Using a steel plant 500m 3 Coal-injection combustion-supporting test was carried out in blast furnace, and the energy-saving effect of combustion-supporting agent on blast furnace coal-injection combustion-supporting was investigated with 15 days as a test period. The type of coal injected is anthracite. The equipment is the blast furnace coal injection device of equipment embodiment 1.

[0067] In the first phase of the test, about 10% of blast furnace dust, about 10% of mine ash, about 20% of dolomite, about 20% of converter dust, and about 40% of limestone were used as the combustion improver in the first phase of the test. The comprehensive composition is: CaO about 10%, MgO about 10%, CaCO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| combustion efficiency | aaaaa | aaaaa |

| combustion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com