A kind of building external wall thermal insulation coating

A technology for thermal insulation and building exterior walls, applied in the direction of coating, etc., can solve the problems that molecules are not easy to move at will, poor thermal insulation effect, low mechanical strength, etc., and achieve good elastic deformation performance, easy construction, and high compressive strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 Fly ash zeolite preparation

[0024] Take the fly ash from Taiyuan No. 1 Thermal Power Plant and pass it through a 200-mesh sieve, weigh 45g, add 450ml of 3mol / L NaOH solution to mix into a slurry, stir at 100°C (300r / min) for 2 hours, centrifuge and take the supernatant for later use; Add 7g NaAlO to it 2 , after stirring (2500r / min) for 30min, the prepared silica-alumina gel was transferred to a homogeneous reactor, and after closed reaction at 120°C for 3h, it was centrifuged, and the solid phase was repeatedly washed with deionized water until the pH value of the filtrate was about was 8.5, and the washed product was dried at 100°C for 24 hours to obtain fly ash zeolite.

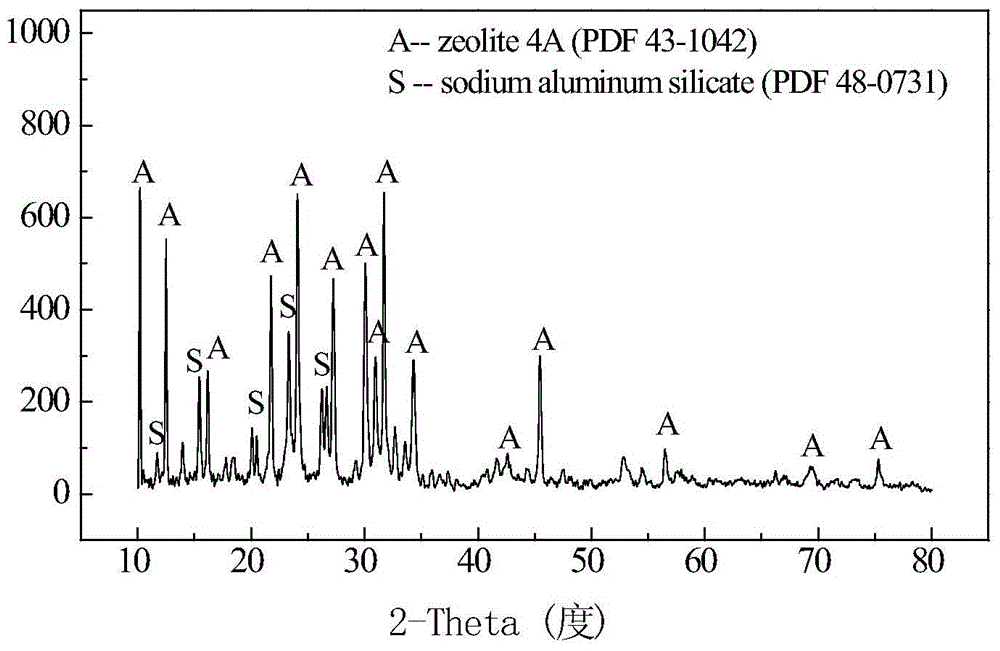

[0025] The Fly ash zeolite samples were analyzed by the Frontier FT-IR infrared analyzer of Perkin Elmer Company in the United States. The results are as follows: figure 1 shown. 1002cm -1 The absorption peak that appears nearby is the asymmetric stretching vibration band of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com