Method for drying wet D-ribose crystal

A ribose and crystallization technology, applied in chemical instruments and methods, monosaccharides, sugar derivatives, etc., to achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

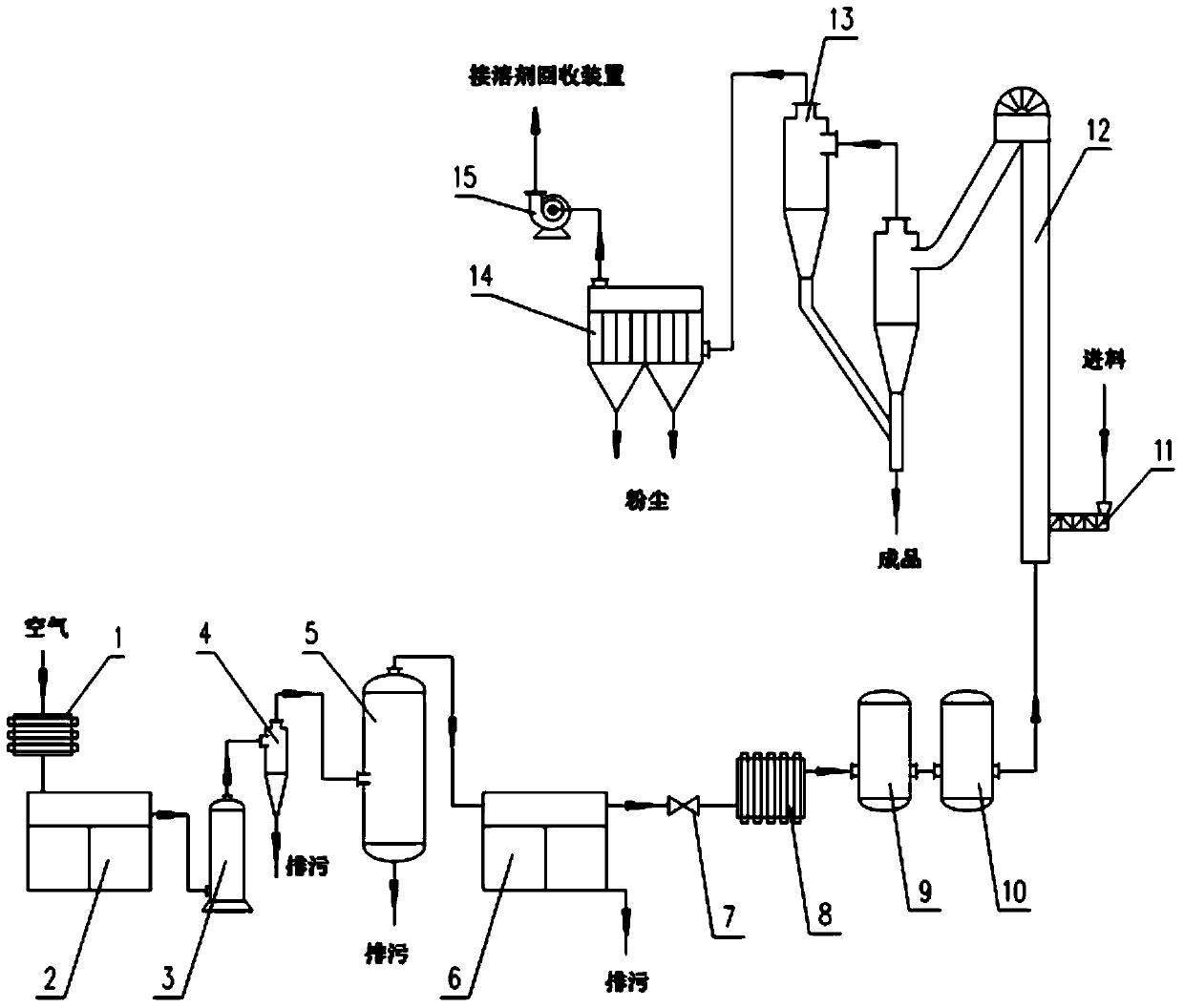

[0034] refer to figure 1 Schematic diagram of drying process and equipment connection for wet D-ribose crystallization, the ambient temperature is 25°C, and the relative air humidity is 40%.

[0035] A method for drying the wet D-ribose crystals obtained from the separation and extraction of the fermentation broth, the steps are:

[0036] (1) Use the primary filter to preliminarily remove impurities from the air to be dried, then use an air compressor to compress the air to 0.7MPa, then use a cooler to reduce the air to 30°C, and use a cyclone separator to remove the condensed oil in the air and water removal;

[0037] (2) Use a cold dryer and control the pressure dew point temperature of the cold dryer to 3°C, further cool down and condense the compressed air obtained in step (1), remove oil and water, and obtain dehumidified air;

[0038] (3) Adjust the air pressure after dehumidification (step 2) to 6.0KPa through the regulating valve, and then heat the depressurized air ...

Embodiment 2

[0044] The basic steps are the same as in Example 1, the ambient temperature is 33°C, and the relative air humidity is 60%.

[0045] Different from embodiment 1 in the step is:

[0046] Use an air compressor to compress the air to 0.6MPa, and then use a cooler to lower the air to 35°C;

[0047] Use a cold dryer and control the pressure dew point temperature of the cold dryer to 2°C;

[0048] Adjust the dehumidified air pressure to 5.0KPa through the regulating valve, then heat the depressurized air to 45°C through the heater, and then filter through the two-stage filter to obtain an almost dry temperature with a relative humidity of only 1.7%. Hot, clean, dry air.

[0049] Centrifuge solid-liquid separation to obtain D-ribose wet crystals 350kg, moisture content 6.5%. Wet crystals of D-ribose are fed into the drying column at a uniform speed from the feeder, and fully contact with dry air (the mixing ratio of air and wet D-ribose crystals is expressed in m 3 : Kg is 6:1), ...

Embodiment 3

[0052] The basic steps are the same as in Example 1, the ambient temperature is 36°C, and the relative air humidity is 70%.

[0053] Different from embodiment 1 in the step is:

[0054] Use an air compressor to compress the air to 0.5MPa, and then use a cooler to lower the air to 40°C;

[0055] Use a cold dryer and control the pressure dew point temperature of the cold dryer to 4°C;

[0056] Adjust the dehumidified air pressure to 5.5KPa through the regulating valve, and then heat the depressurized air to 50°C through the heater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com