Wire harness feeding mechanism

A conveying mechanism and wire feeding technology, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of increasing the burden on enterprises, breaking the wire harness, and increasing the production cost of wires, and achieves safe and stable operation and use. High reliability and smooth wire transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention will be further described:

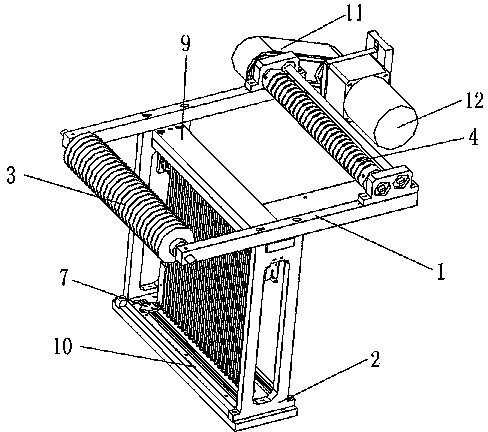

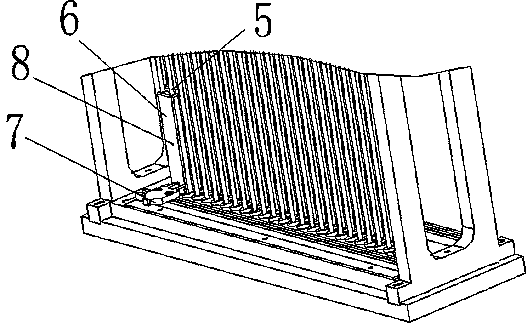

[0016] Such as Figure 1-2 As shown, a wiring harness wire feeding mechanism includes a horizontal frame 1, a vertical protection frame 2, a front wire tensioning shaft 3, a rear wire tensioning shaft 4, several vertical columns 5, a wire passing plate 6, an inductor 7, The motor 12 and the conveying mechanism are respectively connected with a front wire tensioning shaft 3 and a rear wire tensioning shaft 4 at the front and rear of the horizontal frame 1, and a vertical protective frame 2 is connected below the middle of the horizontal frame 1, and the vertical Two rows of vertical columns 5 are arranged between the upper connection plate 9 and the lower connection plate 10 on the protection frame 2, each row of vertical columns 5 includes twenty-six vertical columns, and the two rows of vertical columns 5 are arranged at intervals .

[0017] The wire passing board 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com