Soldering Tooling for Antenna Backing Micro Connectors

A technology of miniature connectors and welding tooling, which is applied in welding equipment, auxiliary devices, metal processing, etc., to achieve the effect of uniform heating and sufficient return of hot air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

[0023] The present invention is different from the conventional method of printing solder paste in surface mounting technology (SMT), and uses a tool for applying solder paste on a connector with a special structure.

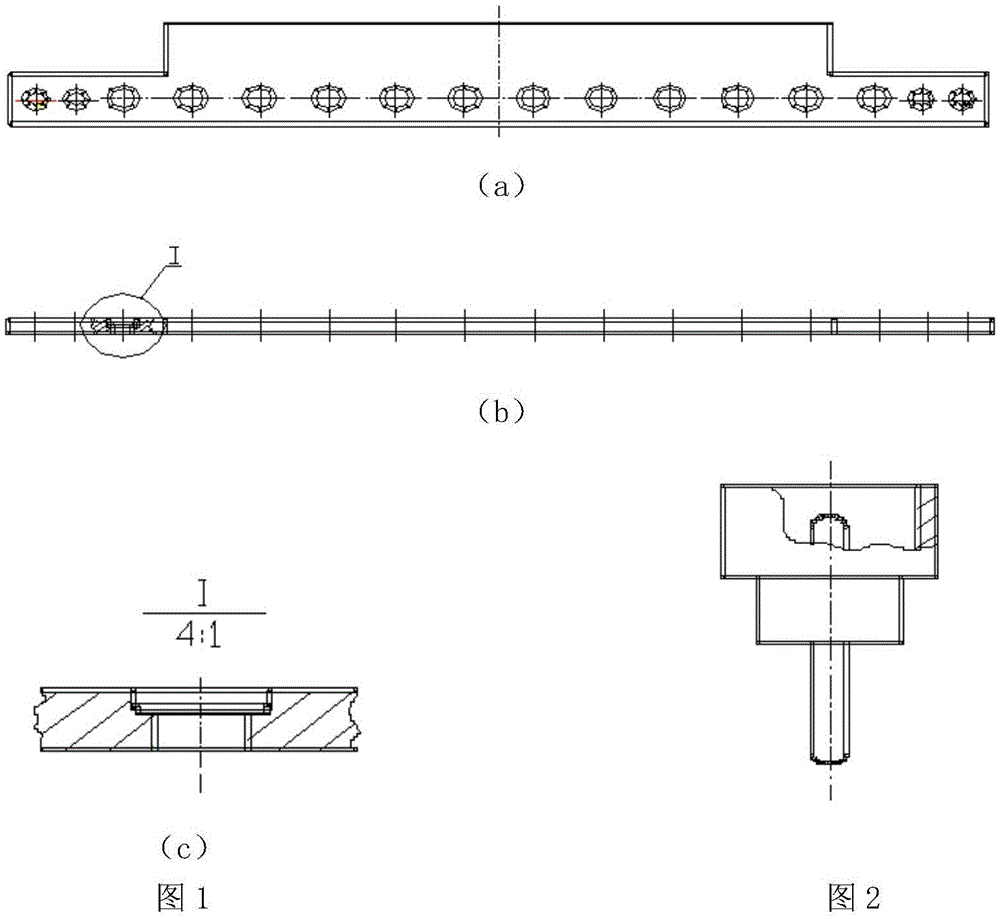

[0024] The invention includes a set of tools for applying solder paste and a pair of frames.

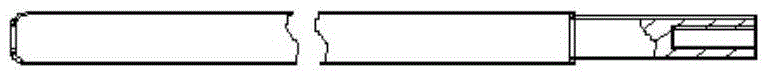

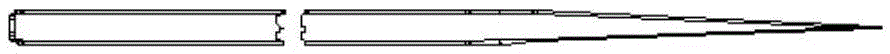

[0025] The solder paste coating tool is composed of copper rod 2 and steel needle 1, the most critical size of copper rod 2, see image 3 Middle right end—the size of the shaft end matched with the inner ring surface of the miniature connector 3, the assembly relationship belongs to the base hole system in the shaft and the hole, and the clearance fit is preferred Process the shaft end size of the copper rod 2 within the tolerance range, and try it with the micro ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com