Designing method for cutter used for drilling composite material component and cutter

A technology of composite material components and design methods, which is applied in the directions of drilling tool accessories, drilling/drilling equipment, and components of boring machines/drilling machines, etc., can solve problems such as easy delamination, and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

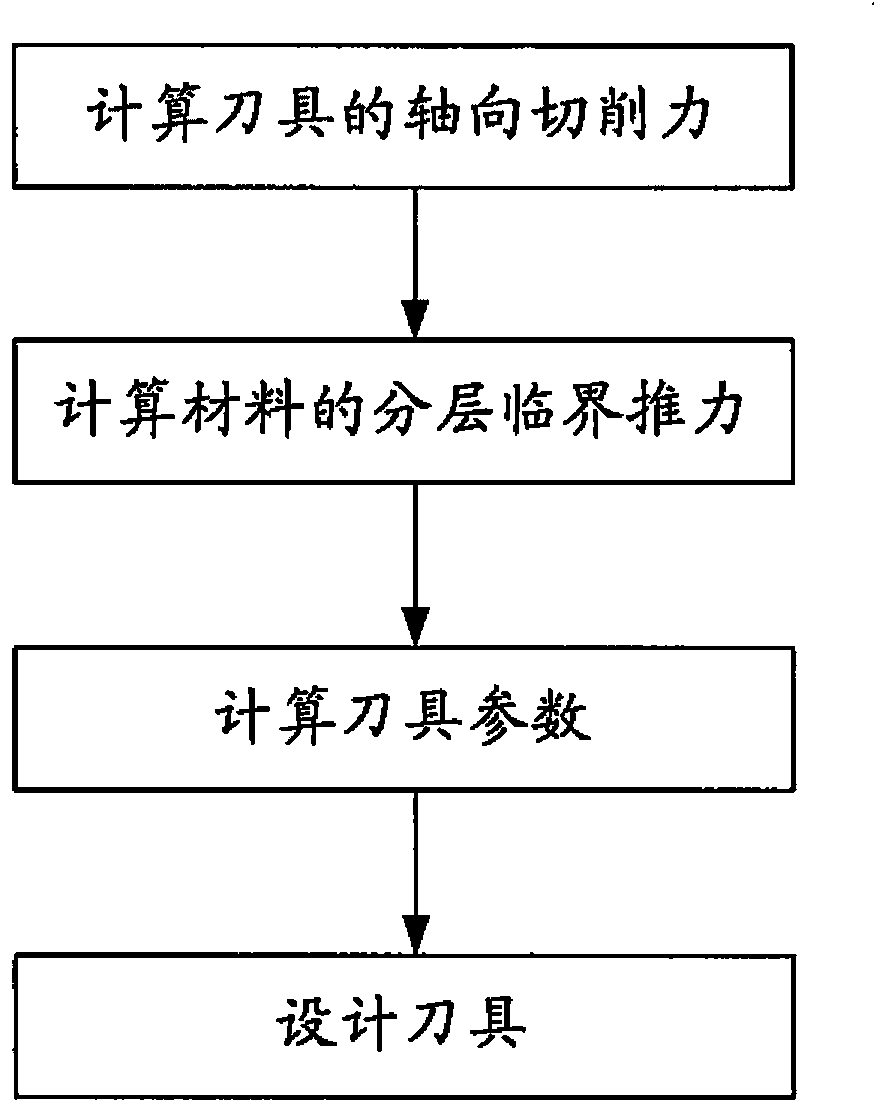

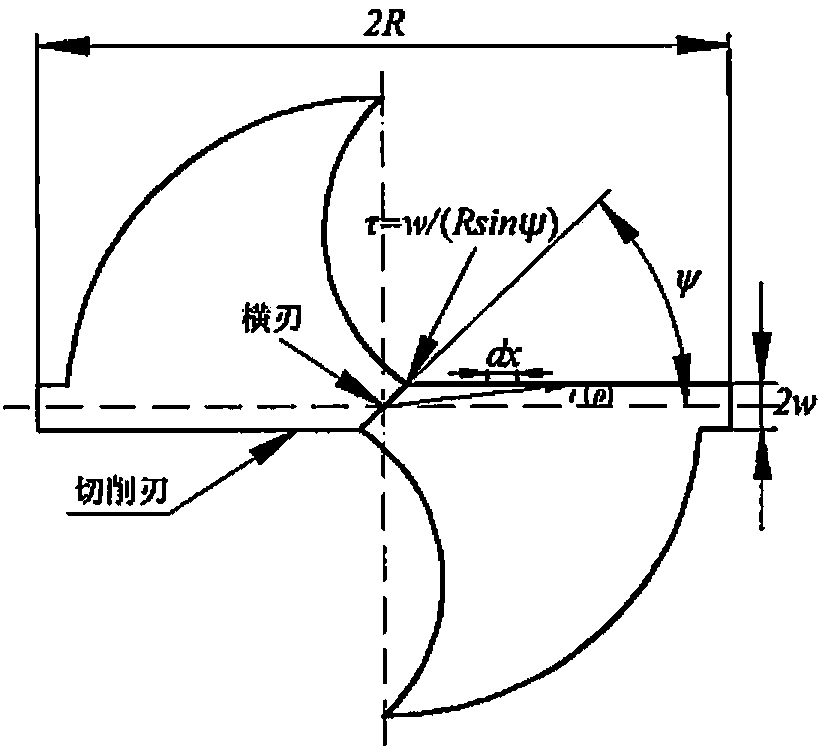

Method used

Image

Examples

Embodiment Construction

[0030]Step drill drilling tools can be considered as a combination of multi-stage drill bits. Here, such tools may include two-level drilling tools, three-level drilling tools, and further-level drilling tools. For two-stage drilling tools, there are upper-stage drills for drilling holes and lower-stage drills for reaming and larger diameters. For three-level drilling tools, it includes the uppermost drill bit for drilling and the smallest diameter, the lowest drill bit for reaming and the largest diameter, and the intermediate drill bit for reaming and the diameter between the first two , wherein the intermediate drill bit can be regarded as a lower-level drill bit for reaming, and can be regarded as a higher-level drill bit for reaming. For more levels of drilling tools, it includes the uppermost level drill bit for drilling and the smallest diameter, the lowest level drill bit for reaming and the largest diameter, and the role for reaming and the diameter is between the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com