Method for machining vacuum frozen carrots

A processing method and technology of vacuum freezing, applied in the direction of preservation of fruits/vegetables by freezing/refrigeration, preservation of fruits/vegetables with sugar, etc., can solve the problems of damage to the health of consumers, a narrow range of choices, and a small variety of dried carrot products, etc. Achieve the effect of avoiding discoloration, simple production process and rapid dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: a kind of processing method of vacuum freezing carrot, comprises the following steps:

[0017] Select high-quality fresh carrots with smooth skin, orange-yellow and bright color, thick and thin body, uniform size, no forks, no cracks, clean and dry for later use;

[0018] Cut the dried carrots into 2cm-thick slices, soak them in 4% glucose water for 10 minutes, spread the soaked carrot slices evenly in the freeze-drying tray, and then put them into the quick-freezing track for quick-freezing. The core temperature reaches -20°C and maintains for 0.4h;

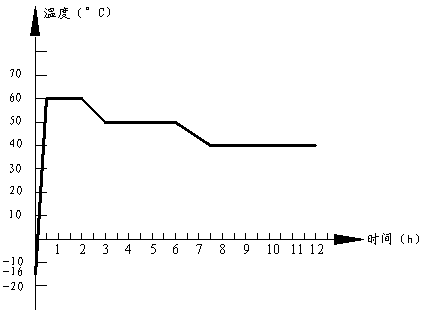

[0019] Push the quick-frozen carrot slices into the freeze-drying bin, put the temperature sensor in place, close the hatch, keep a vacuum of 80-100Pa, raise the temperature to 55°C at a uniform speed within 0.4h, and keep it for 1.3h; keep the temperature within 0.9h Reduce the temperature to 47°C at a constant speed and keep it for 2.0h; drop the temperature to 36°C at a constant speed for 1.4h and keep i...

Embodiment 2

[0020] Embodiment 2: a kind of processing method of vacuum freezing carrot, comprises the following steps:

[0021] Select high-quality fresh carrots with smooth skin, orange-yellow and bright color, thick and thin body, uniform size, no forks, no cracks, clean and dry naturally for later use;

[0022] Cut the dried carrots into 3cm-thick slices, soak them in 6% glucose water for 9 minutes and spread them evenly in the freeze-drying tray, then put them into the quick-freezing track for quick-freezing. When the central temperature of the carrot slices reaches -16℃, keep 0.6h;

[0023] Push the quick-frozen carrot slices into the freeze-drying bin, put the temperature sensor in place, close the hatch, keep the air at 80-100Pa, raise the temperature to 60°C at a constant speed within 0.5h, and keep it for 1.5h; keep the temperature at a constant speed for 1h Drop to 50°C and keep for 3h; 1.5h to drop the temperature to 40°C at a constant speed and keep for 4.5h to prepare carrot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com