Factory high-yield cultivation method for king oyster mushrooms and needle mushrooms

A cultivation method and technology of Flammulina velutipes, applied in botany equipment and methods, horticulture, application, etc., to achieve the effects of good air permeability, high output efficiency, and full utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

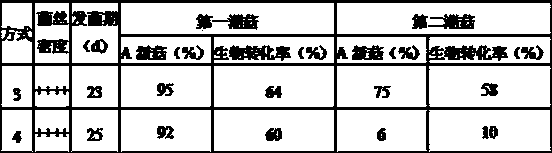

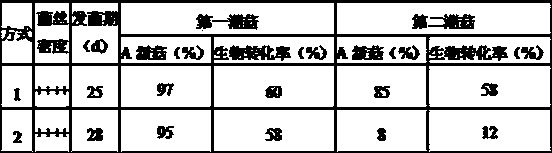

Examples

Embodiment Construction

[0023] Method 1: In this example, the cultivation material of Pleurotus eryngii has the following components and mass ratio: miscellaneous sawdust 25%, corn cob 20%, bagasse 20%, wheat bran 25%, corn flour 5%, soybean meal 5%. All are the quality of dry substance, and the sum of proportioning is 100%, add the expanded perlite of above these materials total mass 12%.

[0024] Pleurotus eryngii factory high-yield cultivation method:

[0025] ① Mixing material: Prepare various raw and auxiliary materials according to the cultivation material formula, first mix the basic ingredients (all raw and auxiliary materials except expanded perlite) evenly, control the water content at 63%-65%, and then mix the expanded perlite Adjust the water content to 82%-85%, and finally mix the basic ingredients with expanded perlite (about 20 minutes);

[0026] ② Bagging: Use a polypropylene plastic bag with a specification of 17cm×35cm×0.005cm, put on a collar after loading the material, and insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com