Lossless spiral conveying device

A technology of spiral transmission and spiral blades, which is applied in the field of conveying systems, can solve the problems of crop grain skin rupture, economic value decline, and damage to crop grains, etc., to achieve the effect of increasing completeness, ensuring cleanliness, and increasing conveying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

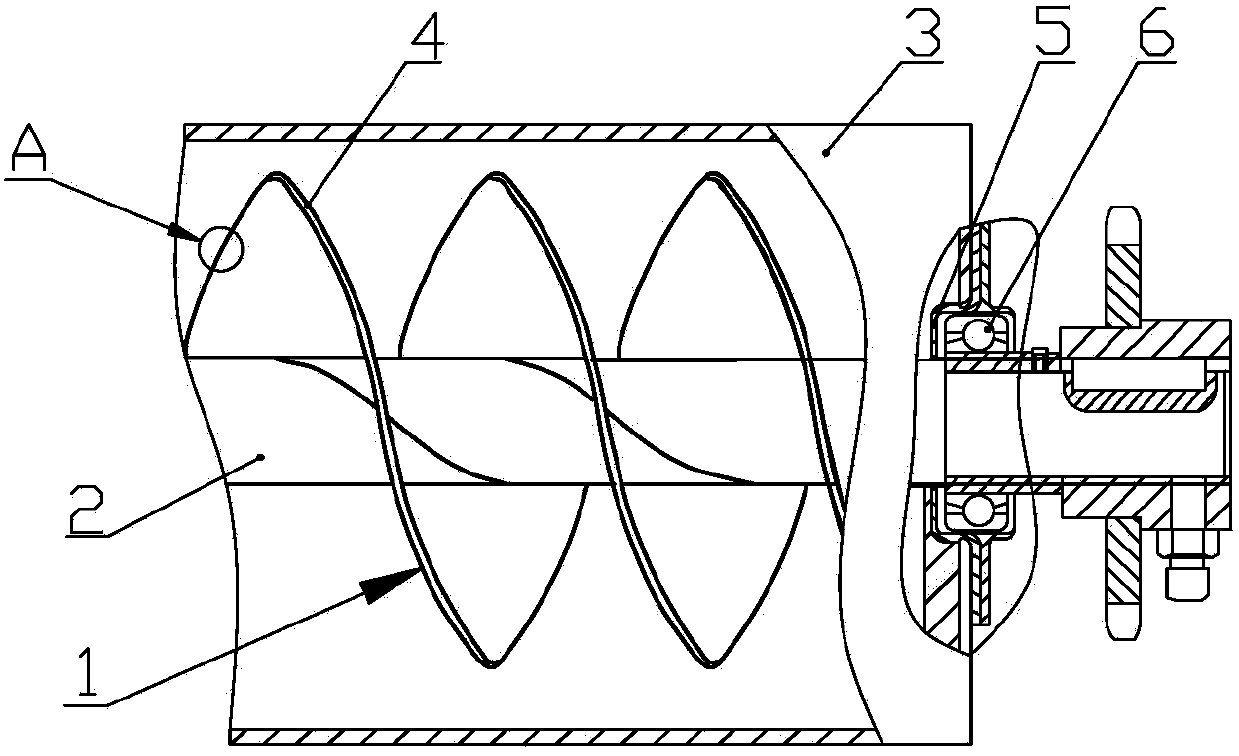

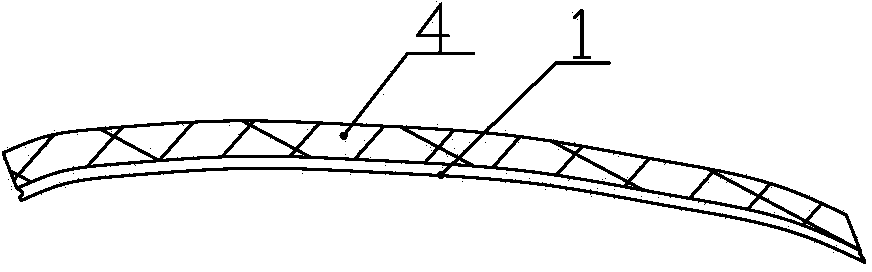

[0018] Such as figure 1 with figure 2 As shown, a non-destructive screw conveying device includes two or three conveying screw blades 1, a rotating shaft 2, a conveying tubular cavity 3, a flexible rubber layer 4, an annular protective cover 5 and a bearing 6.

[0019] The rotating shaft 2 axially passes through the conveying tubular cavity 3 , and the two ends of the rotating shaft 2 are installed in bearing seats on the machine frame through bearings 6 . The conveying screw blade 1 is helically arranged on the outer wall of the rotating shaft 2 inside the conveying tubular cavity 3 . The flexible rubber layer 4 is detachably fixed at the edge of the conveying helical blade 1 and extends along the helical direction of the blade.

[0020] After the flexible rubber layer 4 is set on the outer edge of the spiral blade 1 for conveying, the flexible rubber layer 4 is in direct contact with the crop grains during the conveying process, so it will not damage the crops, destroy it...

Embodiment approach 2

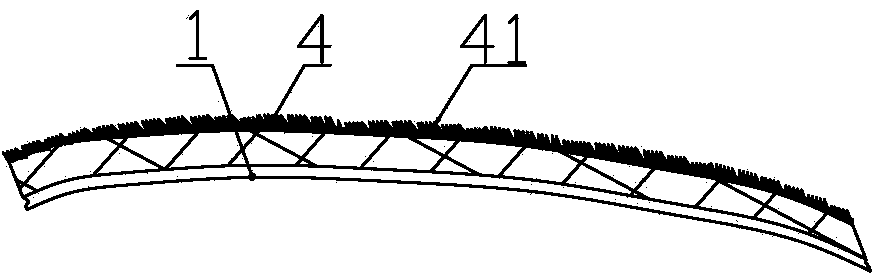

[0023] Such as figure 1 with image 3 As shown, the difference from the above-mentioned embodiment is that: on the basis of the above-mentioned embodiment, a brush-shaped sleeve 41 is fixedly arranged at the edge of the flexible rubber layer 4 , and the brush-shaped sleeve 41 is along the The entire edge of the flexible rubber layer 4 extends, and the peripheral edge of the brush-shaped sleeve 41 is in contact with the inner edge of the delivery tubular cavity 3 . The brush part of the brush-shaped sleeve 41 is made of wear-resistant material. This can not only prolong the use time of the non-destructive screw conveying device, but also the peripheral edge of the brush-shaped sleeve 41 contacts the inner edge of the conveying tubular cavity 3, which can realize complete conveying without damage and residue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com