Electrical heating tube

A technology of electric heating tube and heating power, applied in the direction of heating element shape, etc., can solve the problems of damage to heating objects, poor curvature of electric heating tube, uneven heating distribution, etc., to improve the performance of adapting to the environment, improve the field of use, The effect of constant heating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

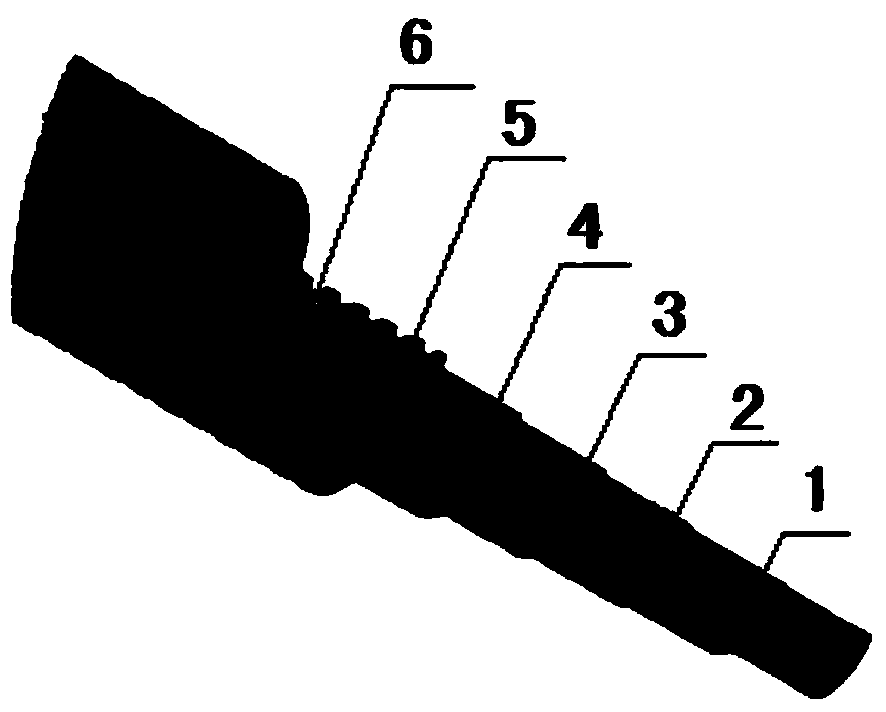

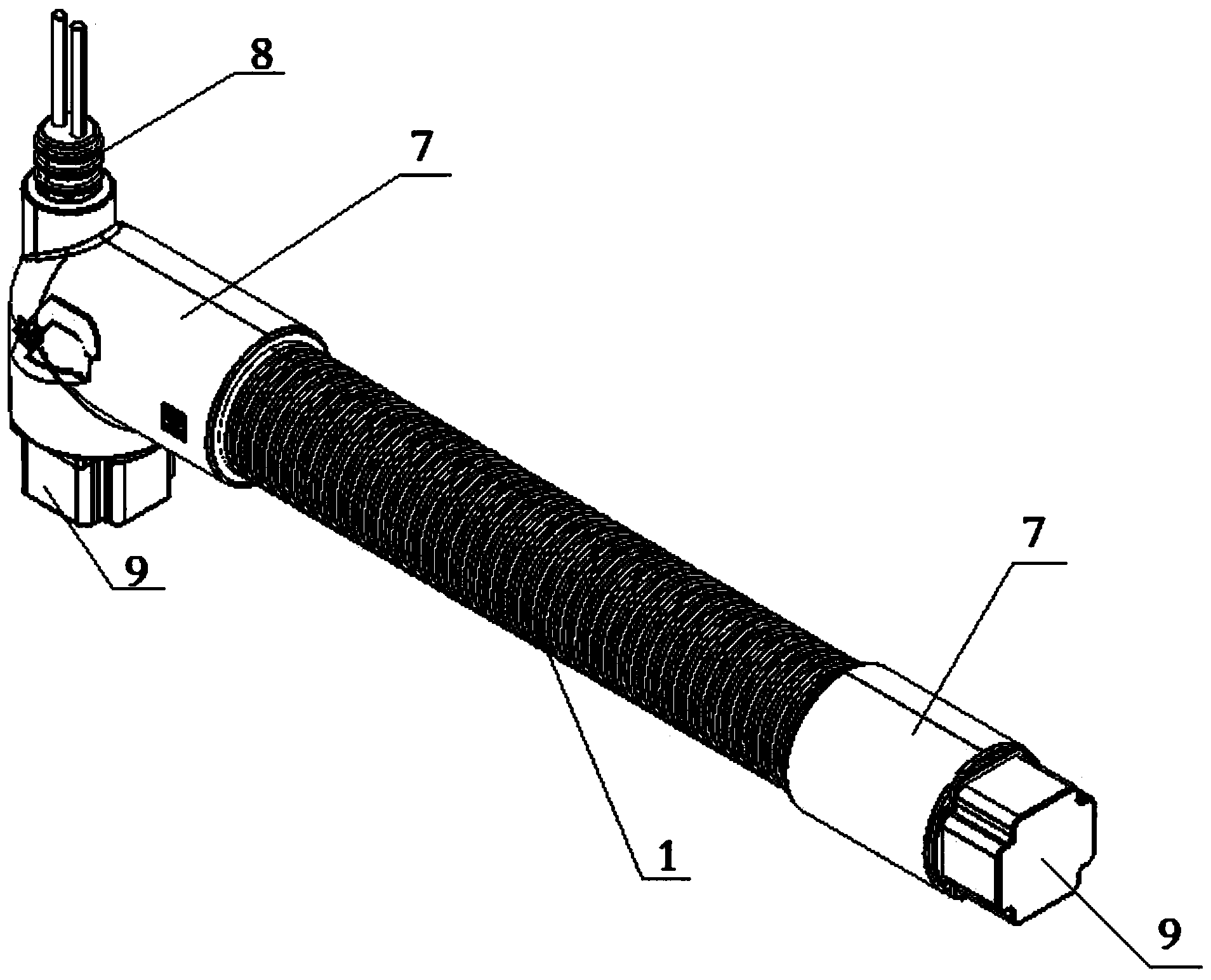

[0031] This embodiment describes an electric heating tube, its structure is as follows figure 1 , figure 2 As shown, the electric heating tube includes a pipe body 1 and a joint part 9 for transporting liquid. The joint part 9 is fixed on both ends of the pipe body 1 through the injection molding part 7, and a layer of mesh is coated on the pipe body 1 and the joint part 9. Shaped tubular heating carrier 4, the heating carrier is a mesh heating layer made of carbon fiber heating wires and fire-resistant and flame-retardant fiber wires mixed and woven. The injection molding part 7 at one end of the electric heating tube is provided with a power line lead-out interface 8, and the tubular heating carrier 4 adopts a crimping contact process on the circuit connection to realize an effective connection between the carbon fiber heating wire and the input wire.

[0032] The crimping contact between the power cord and the heating wire in this embodiment: According to the physical cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com