Movement vision measurement method of rocket engine nozzle and high-brightness infrared light-emitting device used in method

A rocket engine and infrared light-emitting technology, which is applied in measuring devices, photogrammetry/video metrology, surveying and navigation, etc., can solve the problem that the camera image plane cannot correctly identify cooperation targets, etc., and achieve simple structure and improved accuracy , The effect of clear collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] The specific embodiment one, a kind of rocket engine nozzle movement visual measurement method described in this specific embodiment, it comprises the following steps:

[0022] Step 1. Arrange multiple infrared light-emitting points on the outer surface of the rocket engine nozzle, and connect the infrared light-emitting points in parallel with multiple channels to form a light-emitting circuit. Each channel is composed of two infrared light-emitting points and an adjustable voltage divider resistor. In a series structure, the number of the channels is 2 or 3, and the infrared light-emitting point is realized by a high-brightness infrared light-emitting device,

[0023] Step 2, setting an infrared filter before the lens of the image acquisition device,

[0024] Step 3, connect the image acquisition signal output end of the image acquisition device with the image acquisition signal input end of the visual measurement system control computer,

[0025] Step 4. Aim the len...

specific Embodiment approach 2

[0029] Specific embodiment two, combine Figure 7 Describe this specific embodiment, the difference between this specific embodiment and the visual measurement method of a rocket engine nozzle movement described in specific embodiment 1 is that the light-emitting circuit described in step 1 also includes a power supply VCC, a switch S1 and a circuit pass. The off indicator LED1, the power supply VCC is used to supply power to the light-emitting circuit, the switch S1 is used to control the on or off of the light-emitting circuit, the circuit on-off indicator LED1 is connected in series with the switch S1, and is used to display the on or off of the light-emitting circuit status.

specific Embodiment approach 3

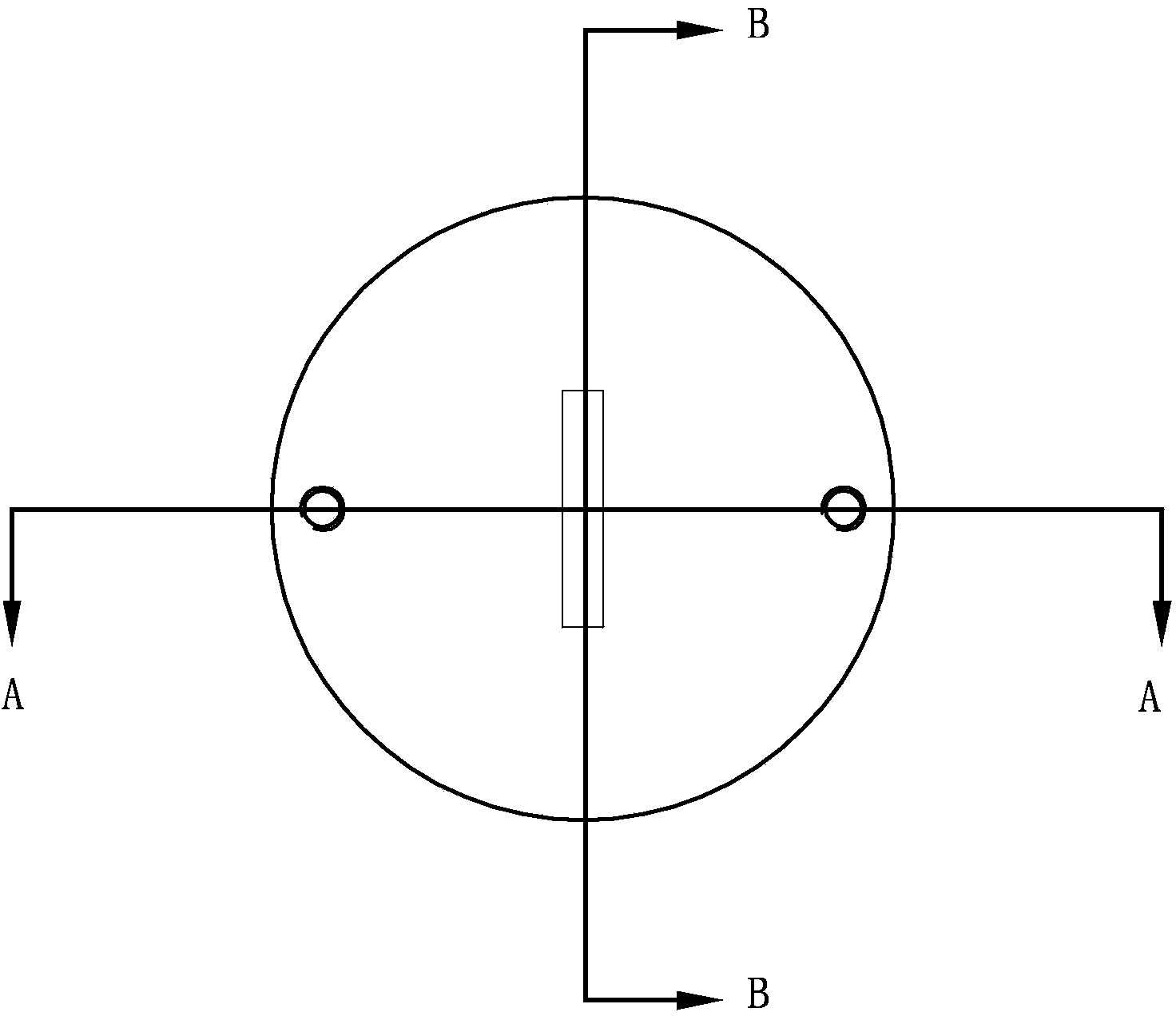

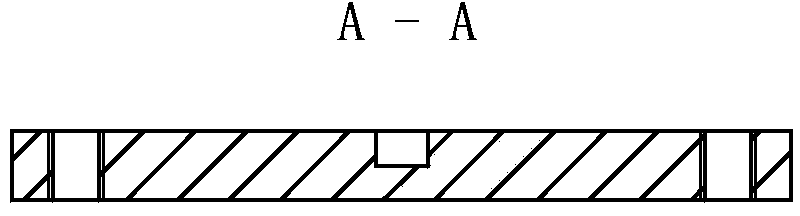

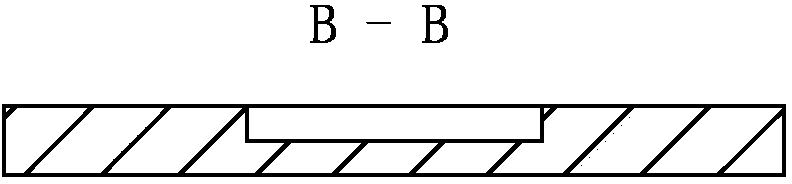

[0030] Specific embodiment three, combine Figure 1 to Figure 6 Illustrate this specific embodiment, the high-brightness infrared light-emitting device used in a kind of rocket engine nozzle motion visual measurement method described in specific embodiment 1 comprises an infrared light-emitting circuit board, an infrared light-emitting diode and a housing, and the infrared light-emitting diode is fixed on On the infrared light-emitting circuit board, the infrared light-emitting diode includes 9 infrared light-emitting cores working in parallel. Both sides of the infrared light-emitting circuit board are processed with symmetrical light holes. The shell includes a shell and a base. The shell is cylindrical structure, the infrared light-emitting circuit board is fixed in the casing, and a through hole is opened in the center of the upper surface of the casing. The positive and negative wires of the infrared light-emitting diode are connected to the external power supply through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com