Metal-medium multilayered structure color-adjustable sun photo-thermal absorbing coating

A multi-layer structure, metal coating technology, applied in solar thermal devices, solar thermal power generation, metal layered products, etc., can solve problems such as limitations, and achieve low cost, easy control of the preparation process, and low infrared thermal emissivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

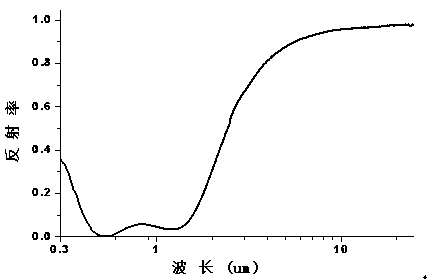

[0025] A purple solar heat absorbing coating and a preparation method thereof.

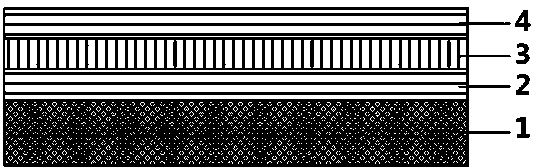

[0026] The solar heat absorbing coating consists of a substrate, an infrared reflective layer, an absorbing layer, and an antireflection layer from bottom to top. The absorbing layer is composed of an aluminum nitride film and a titanium film. The specific film composition is as follows:

[0027] Quartz sheet / Cu / Ti / AlN / Ti / AlN.

[0028] This embodiment takes magnetron sputtering equipment as an example, and its preparation method is as follows:

[0029] Firstly, the quartz wafer was used as the substrate, and the copper film was plated on the quartz wafer by DC magnetron sputtering. The target material used is a metal copper target, and the thickness of the copper film reaches 120 nm by sputtering for 240 seconds.

[0030] Then, DC magnetron sputtering is used to plate titanium film on the copper film. The target used is a metal titanium target. The thickness of the titanium film reaches 24 nanom...

Embodiment 2

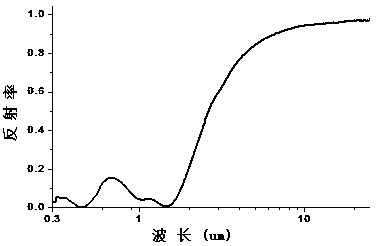

[0034] A yellow-green solar heat absorbing coating and a preparation method thereof.

[0035] The solar heat absorbing coating consists of a substrate, an infrared reflective layer, an absorbing layer, and an antireflection layer from bottom to top. The absorbing layer is composed of an aluminum nitride film and a titanium film. The specific film composition is as follows:

[0036] Quartz sheet / Cu / AlN / Ti / AlN / Ti / AlN.

[0037] This embodiment takes magnetron sputtering equipment as an example, and the preparation method of its absorbing coating is as follows:

[0038] Firstly, the quartz plate was used as the substrate, and the aluminum film was deposited on the quartz plate by DC magnetron sputtering. The target material used is a metal aluminum target, and the thickness of the aluminum film reaches 120 nanometers by sputtering for 240 seconds.

[0039] Then, using metal aluminum as the target material, nitrogen gas was introduced as the reaction gas to plate an aluminum nitr...

Embodiment 3

[0043] A blue solar heat absorbing coating and a preparation method thereof.

[0044] The solar heat absorbing coating consists of a substrate, an infrared reflective layer, an absorbing layer and an antireflection layer from bottom to top. The absorbing layer is composed of an aluminum oxide film and a titanium film. The specific film composition is as follows:

[0045] Aluminum flake / Ag / Al 2 o 3 / Ti / Al 2 o 3 / Ti / Al 2 o 3 .

[0046] This embodiment takes magnetron sputtering equipment as an example, and the preparation method of its absorbing coating is as follows:

[0047] Firstly, the quartz wafer was used as the substrate, and the silver film was plated on the quartz wafer by DC magnetron sputtering. The target used is a metal silver target, and the thickness of the silver film reaches 120 nanometers by sputtering for 150 seconds.

[0048] Then, using metal aluminum as the target material, oxygen was introduced as the reaction gas to coat the aluminum oxide film on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com