Rotating shaft sealing device

A technology of sealing device and rotating shaft, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of limited use, uncompensated shaft eccentricity, polluting the environment, etc., to reduce contact wear, work stably and reliably, Effective sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

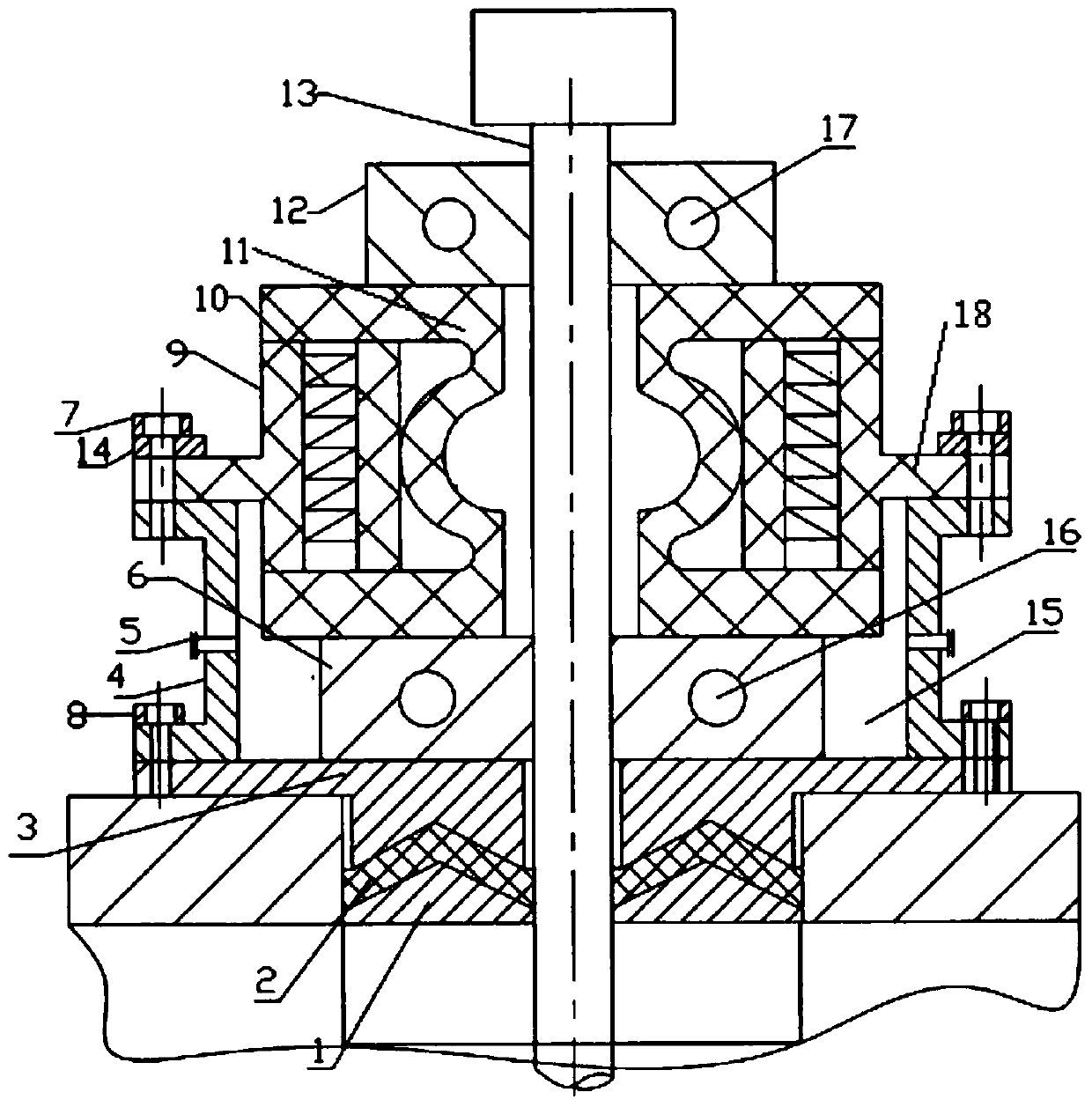

[0011] Such as figure 1 As shown, a rotating shaft sealing device includes a rotating shaft 13, a split branch ring 1 is sleeved on the bottom end of the rotating shaft 13, and a V-shaped sealing packing 2 is installed above the split branch ring 1. The outer side of the upper rotating shaft 13 of the V-shaped sealing packing 2 is covered with a gland 3 with a pressure ring, and a split moving ring-6 is set above the gland 3. On the split surface of the split moving ring-6 Coat the contact surface with the rotating shaft 13 with sealant, and tighten the bolt 16 to make the split moving ring 6 and the rotating shaft 13 rotate fixedly, and a split sealing shell 4 is arranged on the outer side of the rotating shaft 13 above the gland 3 , the upper and lower ends of the split-type sealed casing 4 are respectively bent outwards, and the lower end of the split-type sealed casing 4 is fixedly connected with the gland 3 through bolts 2 8, and the split-type moving ring 1 6 and the spl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com