Method for detecting abnormality of at least one function of infusion assembly

A technology with abnormal functions and components, applied in pressure infusion, pump testing, and devices introduced into the body, etc., can solve problems such as pump program rearrangement, pressure sensor insensitivity, and patient danger, and achieve the effect of accurate blockage control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] micro pump

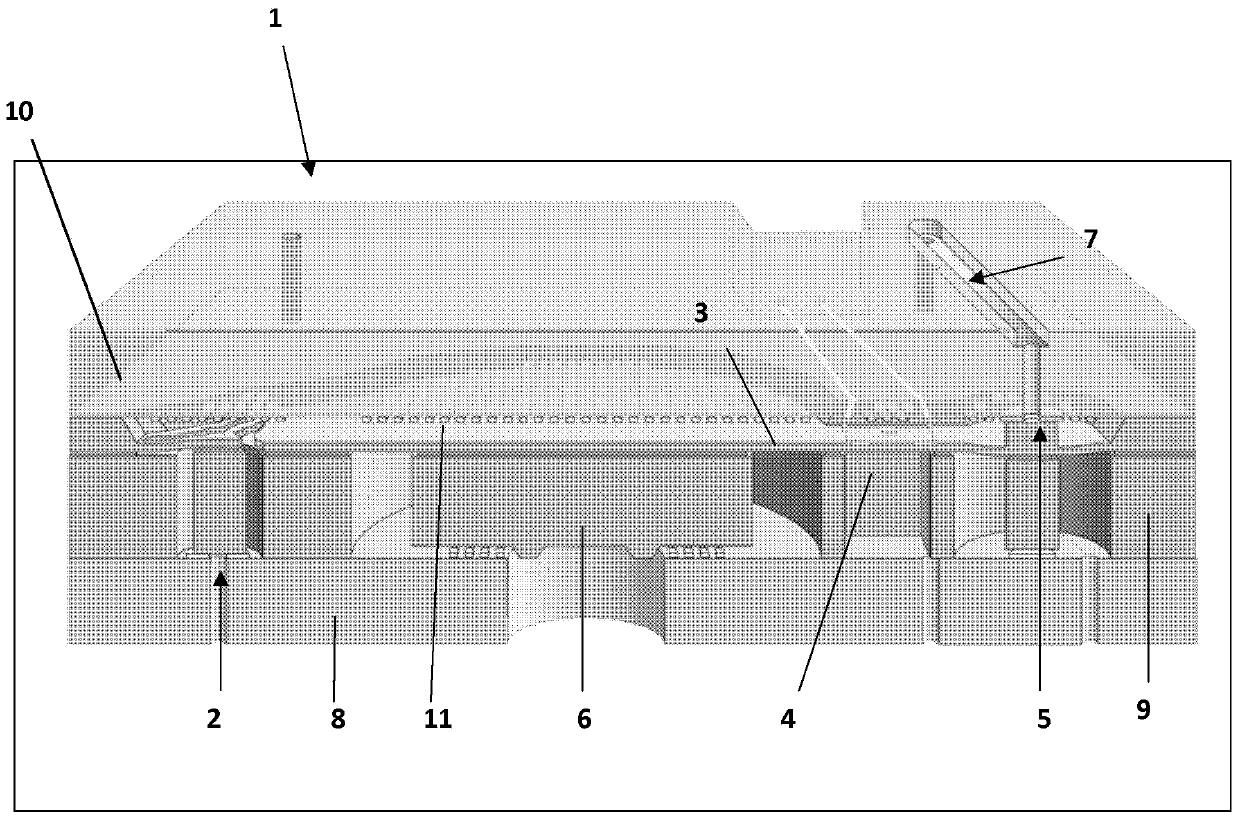

[0037] like figure 1 The micropump 1 shown in is a highly miniaturized and reciprocating diaphragm pumping mechanism. It is manufactured from silicon and glass using a technology known as MEMS (Micro Electro Mechanical Systems). It contains the inlet control element, here the inlet valve 2 , the pumping diaphragm 3 , the function detector 4 allowing the detection of various faults in the system and the outlet valve 5 . The principle of such a micropump is known from the prior art, eg from US5759014.

[0038] figure 1 The pump is shown with a glass layer (blue) as substrate 8, a silicon layer (purple) as second plate 9 affixed to substrate 8 and a second glass layer 10 as top plate affixed to silicon plate 9 ( blue), thus defining a pumping chamber 11 with a volume.

[0039] An actuator (not shown here) connected to a bench top transistor 6 enables controlled displacement of the pumping diaphragm 3, there is also a slot 7 to connect the outlet control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com