A fault detection device and method for an exhaust gas recirculation engine

A technology of exhaust gas recirculation and fault detection, applied in the direction of engine testing, measurement devices, engine components, etc., can solve problems such as reducing engine power, affecting engine power performance, affecting normal engine operation, etc., to eliminate interference and ensure normal operation. Running, avoiding the effect of limiting torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

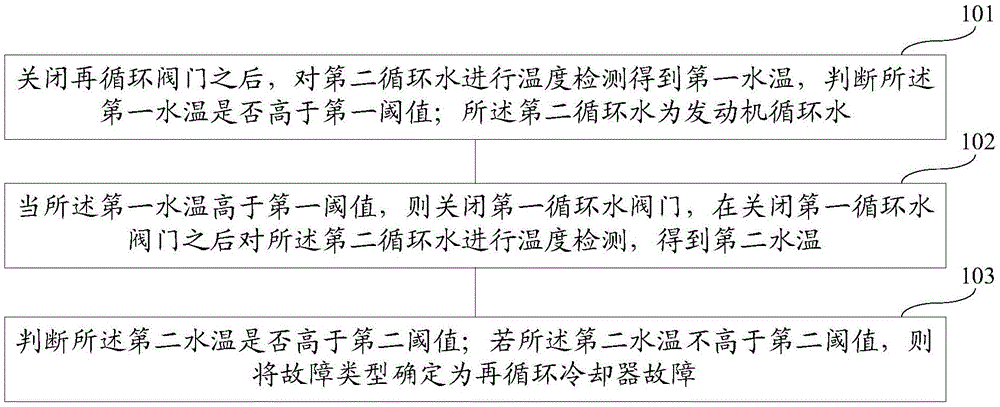

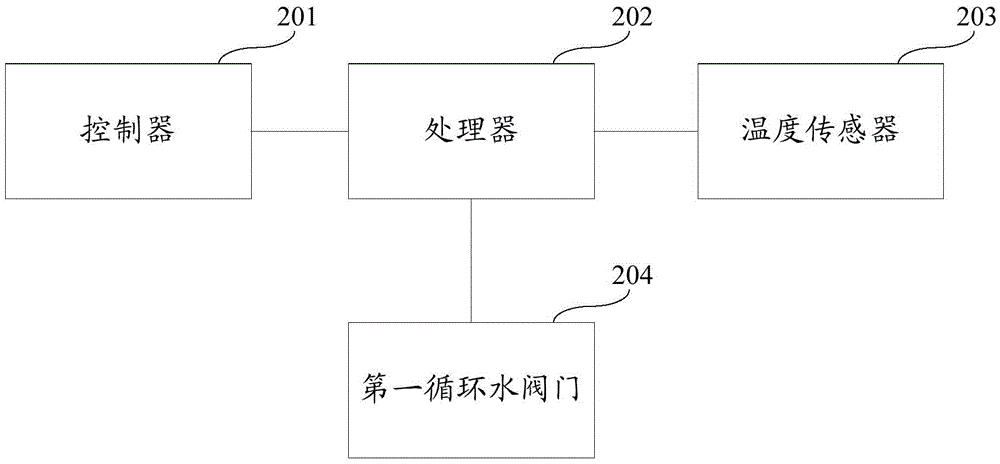

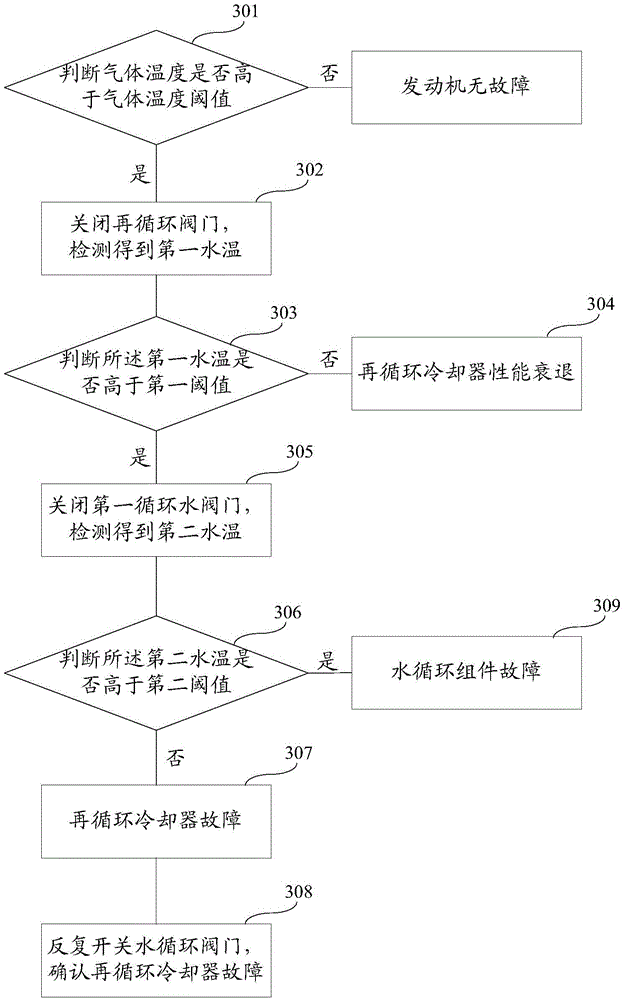

[0044] In the present invention, there are mainly three kinds of fault types aimed at by the fault detection:

[0045] One is the EGRC failure. The so-called EGRC failure is mainly due to the leakage of the EGRC's gas path. The recirculated engine exhaust gas enters the EGRC's water cycle, resulting in a decrease in cooling efficiency and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com