Structural maintenance method and system for concrete floors

A maintenance system and concrete technology, which is applied in building structure, building material processing, construction, etc., can solve the problems of unattended care, large manpower consumption, and high intensity of manual watering, so as to achieve high-efficiency floor structure cracks, prevent The effect of cracks in the floor structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to facilitate the understanding of the structure of the present invention, the following description will be made in conjunction with the accompanying drawings and embodiments.

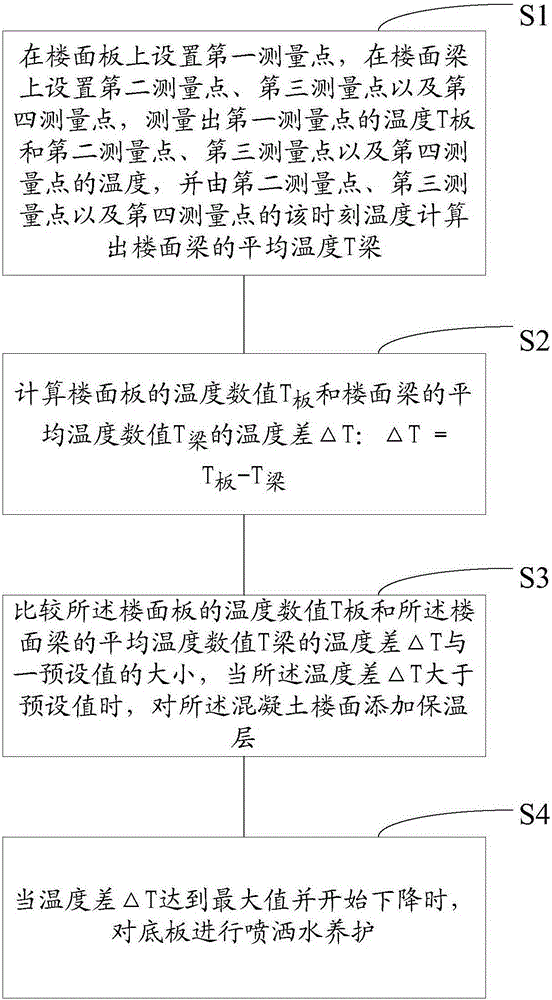

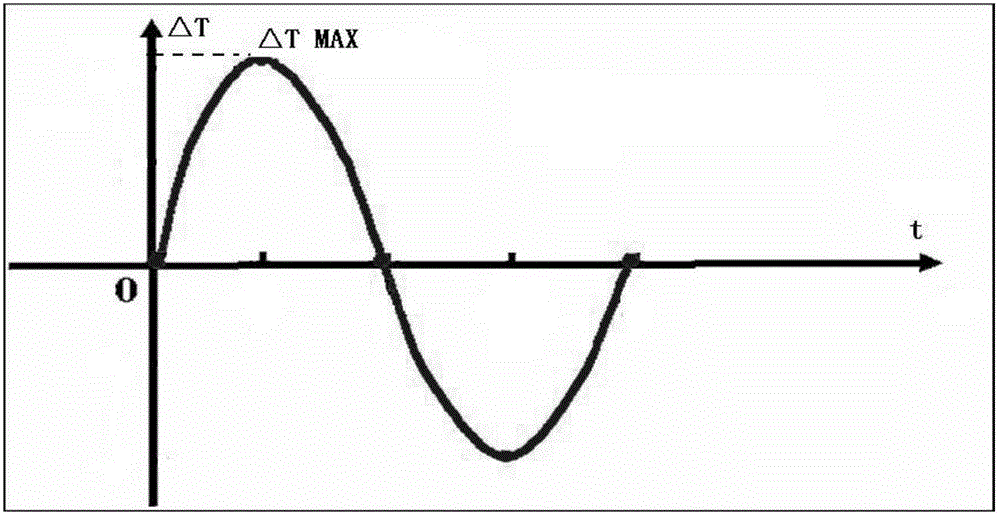

[0028] figure 1 It is a schematic diagram of the measurement positions of concrete floor beams and floor slabs in the concrete floor structure maintenance method, figure 2 It is a flow chart of the concrete floor structure maintenance method.

[0029] combine figure 1 and figure 2 As shown, in the first embodiment, the present invention provides a method for maintaining the structure of a concrete floor, comprising the following steps:

[0030] pouring a concrete floor comprising floor slabs and floor beams fixedly connected beneath said floor slabs,

[0031] S1. In this embodiment, a measurement point is set on the floor slab, marked as: the first measurement point 1, and the first measurement point 1 is set at any point on the cross-section of the middle point of the height of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com