Vacuum evaporation equipment for organic material

An organic material and evaporation technology, which is applied in the field of organic material vacuum evaporation equipment, can solve the problems of automatic control, low precision, slow organic material vacuum evaporation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

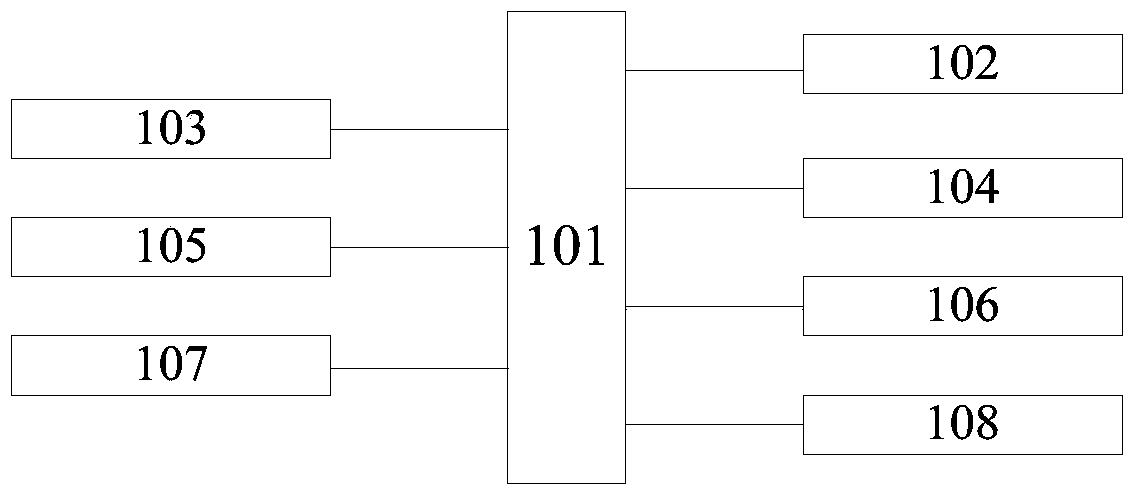

[0039] The invention provides a vacuum evaporation equipment for organic materials, including a vacuum evaporation chamber and an automatic control system;

[0040] Wherein, the vacuum evaporation chamber includes:

[0041] cavity;

[0042] Vacuuming equipment communicated with the cavity;

[0043] A resistance heating beam source furnace arranged in the cavity for heating the evaporation source, a first baffle is arranged above the resistance heating beam source furnace;

[0044] a substrate platform corresponding to the resistance heating beam source furnace, and a second baffle is arranged on the substrate platform;

[0045] a mask storage bin arranged in the cavity;

[0046] A reticle docking system connected to the reticle storage bin for transporting the reticle and docking or separating the reticle from the substrate;

[0047] a mechanical transfer system communicating with the chamber for transferring substrates and connecting or separating the substrates from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com