Coating brushing machine for aluminum alloy rim

A kind of technology of aluminum alloy and coating machine, which is applied in the direction of coating and liquid coating device on the surface, which can solve the problems of inconsistent coating thickness, easy peeling off of coating, uneven application, etc., to achieve short time consumption and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

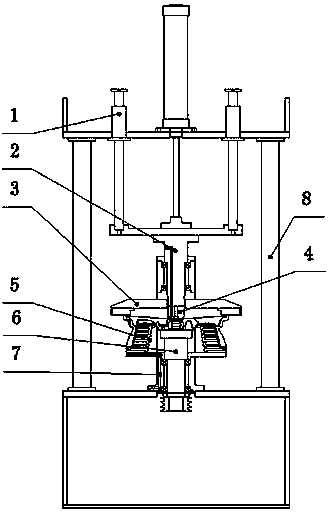

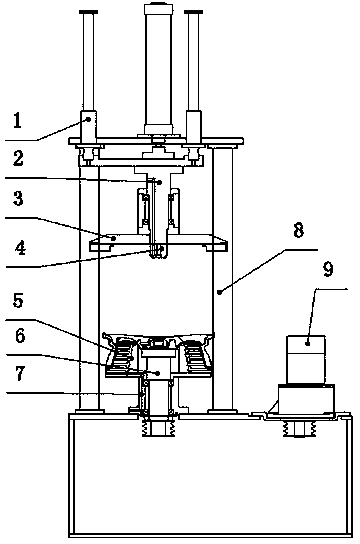

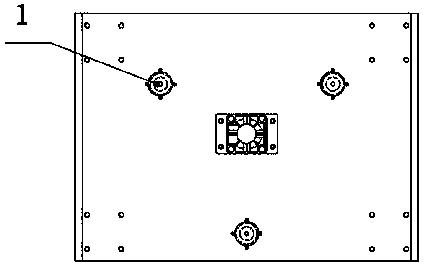

[0014] exist figure 1 Among them, the aluminum alloy rim brush coating machine is composed of a guiding mechanism 1, an upper spindle 2, a pressing mechanism 3, an upper brush 4, a lower brush 5, a lower spindle 6, a support seat 7, a base 8, and a motor 9. The guiding mechanism 1 is fixed on the base 8 and connected with the upper main shaft 2. The upper main shaft 2 is provided with an upper brush 4 and connected with the pressing mechanism 3. The pressing mechanism 3 can move up and down along the guide mechanism 1. The motor 9 and the supporting seat 7 is fixed on the base 8, the lower main shaft 6 is connected with the support base 7, the lower brush 5 is fixed on the lower main shaft 6, and the lower main shaft 6 is provided with a blank and rotates. When working, the pressing mechanism 3 presses down Tight, the paint flows into the upper and lower brushes respectively from the entrance of the support seat 7 and the upper spindle 2 through the diversion groove, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com