Efficient measurement element, device and method for integrated gear errors

An overall error, measuring element technology, applied in the fields of mechanical transmission, precision testing technology and instruments, can solve the problems of small measuring range, non-uniform end face tooth profile, manufacturing difficulty of measuring worm, etc., so as to overcome manufacturing difficulties and shorten measuring time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing, present embodiment is described further:

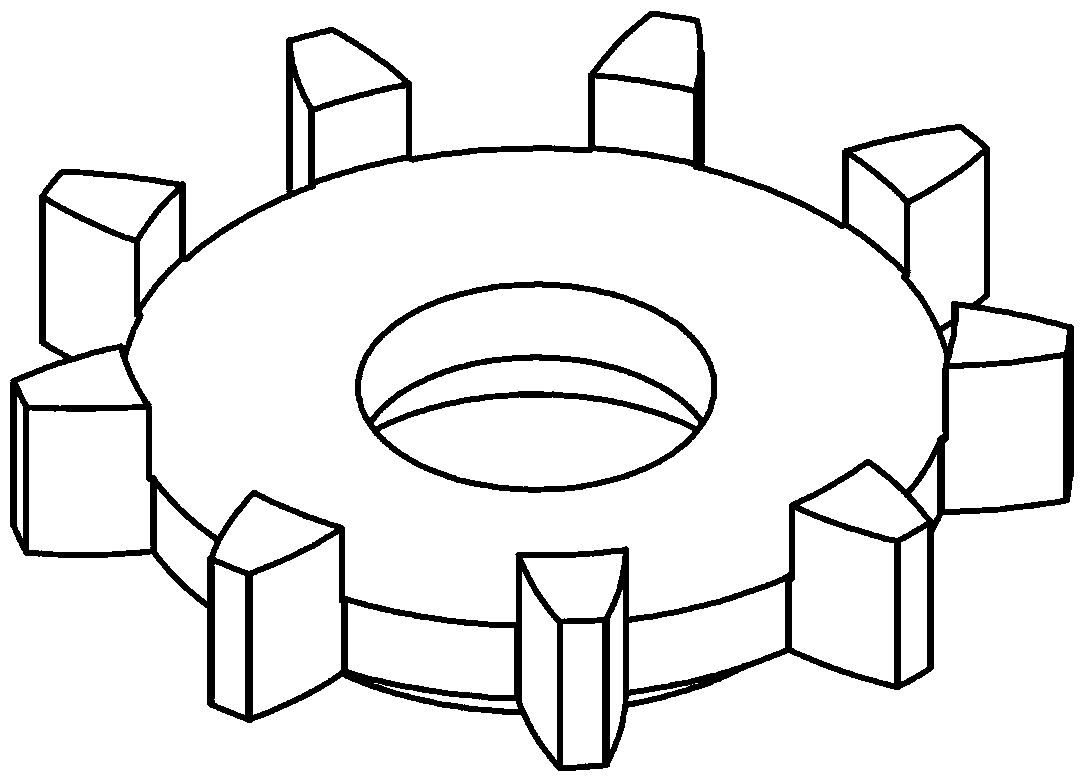

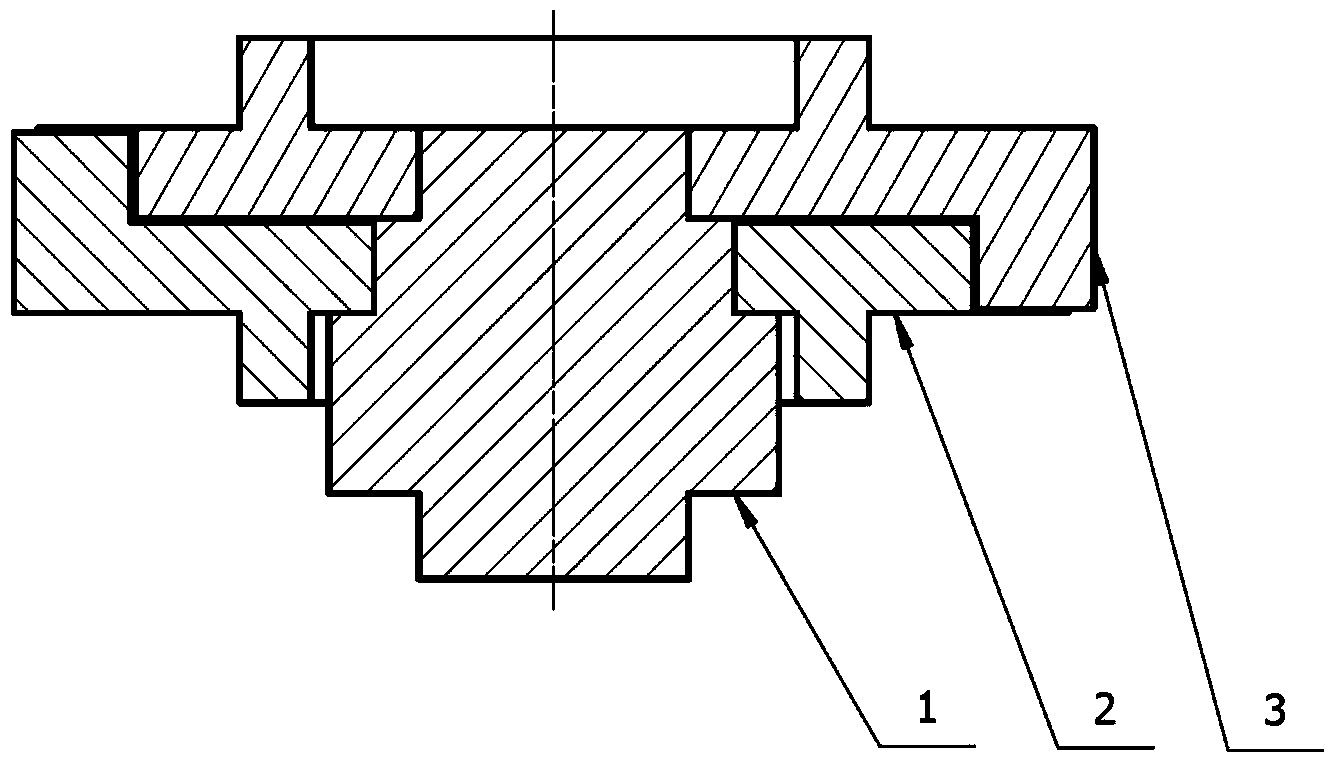

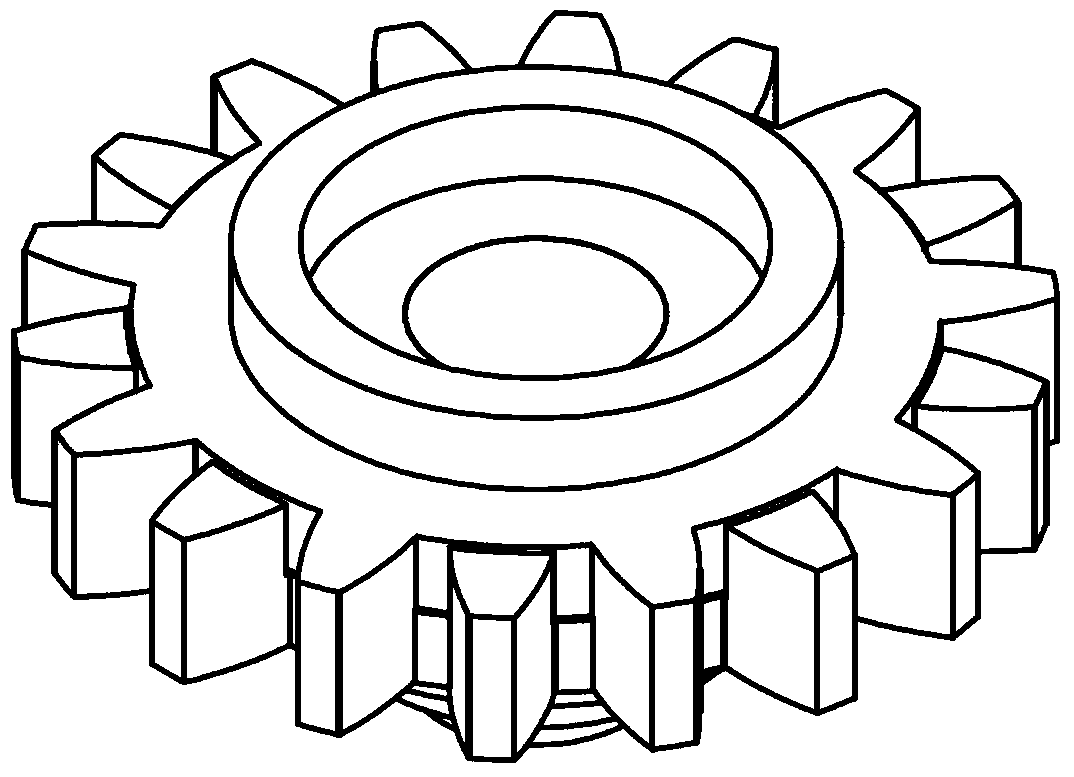

[0042] This embodiment designs and manufactures a combined measuring element composed of two half gears and a high-efficiency overall error measuring device using the combined measuring element, and illustrates the measurement method using the high-efficiency overall error measuring device. In this embodiment, the rolling point scanning measurement of all the teeth of the gear under test is realized by combining the measuring elements, and the angular displacement signal generated by the combined measuring element and the gear under test during the transmission process is converted into an electrical signal through a circular grating, and the data is collected The circuit is input into the computer, and after analysis and calculation and data processing, the overall error, individual error and comprehensive error of the tested gear can be obtained according to the international and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com