Three-tube adaptive anti-roll shock absorber

An adaptive, anti-roll technology, applied in shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of difficult heat dissipation, ineffectiveness, poor heat dissipation effect, etc. Good damping and shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

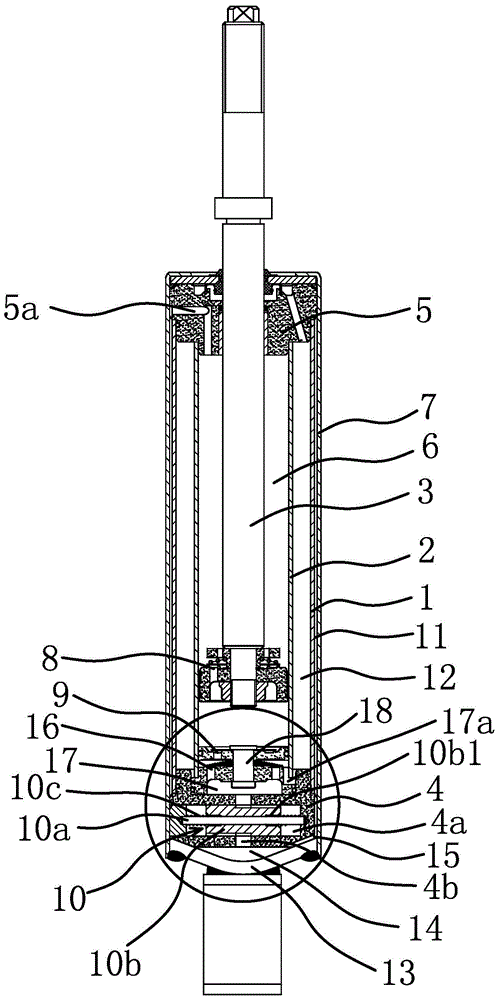

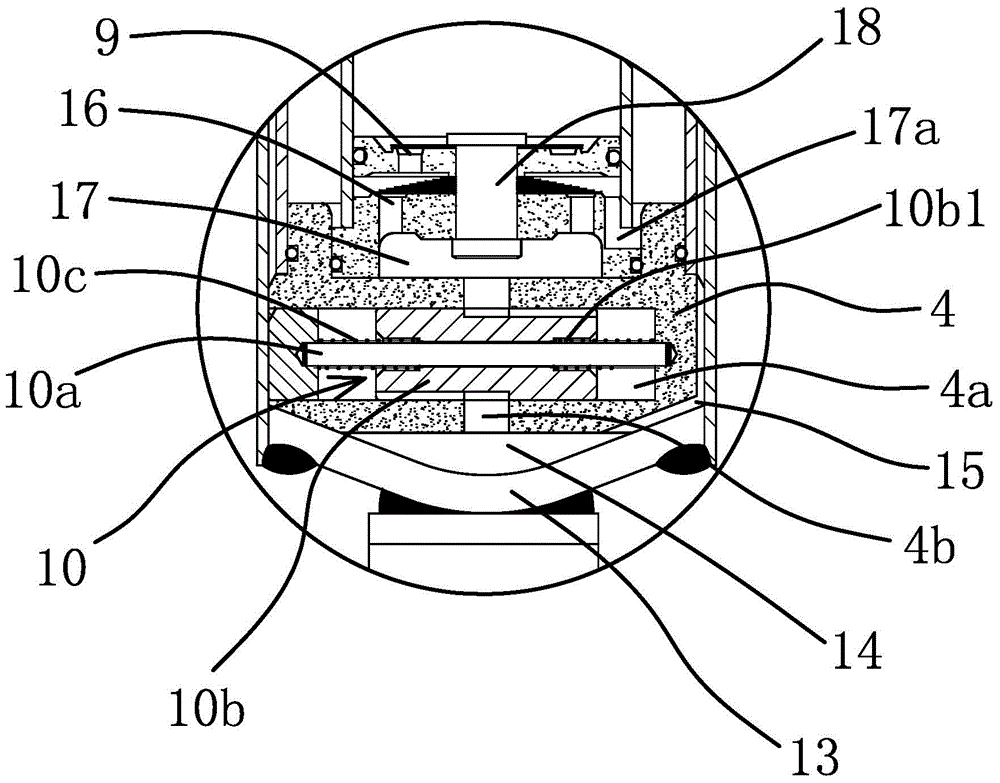

[0029] like figure 1 As shown, the three-tube adaptive anti-roll shock absorber includes oil storage cylinder 1, working cylinder 2, piston rod 3, base 4, guide 5, outer cylinder 7, one-way valve one 8, one-way valve two 9 , damping valve 16 and inertia valve 10.

[0030] Working cylinder 2 is arranged in oil storage cylinder 1, and oil storage cylinder 1 is arranged in outer cylinder 7, and outer cylinder 7 is also the shell of this shock absorber, and guider 5 is fixed on the top of working cylinder 2 and oil storage cylinder 1, and base 4 is fixed on the working The bottom end of the cylinder 2 and the oil storage cylinder 1, and the guide 5 and the base 4 all play a role in positioning the working cylinder 2 and the oil storage cylinder 1, and the circumferential outer walls of the guide 5 and the base 4 protrude slightly from the oil storage cylinder 1 The outer side wall of the outer cylinder 7 is sleeved on the oil storage cylinder 1, and the inner side of the top end ...

Embodiment 2

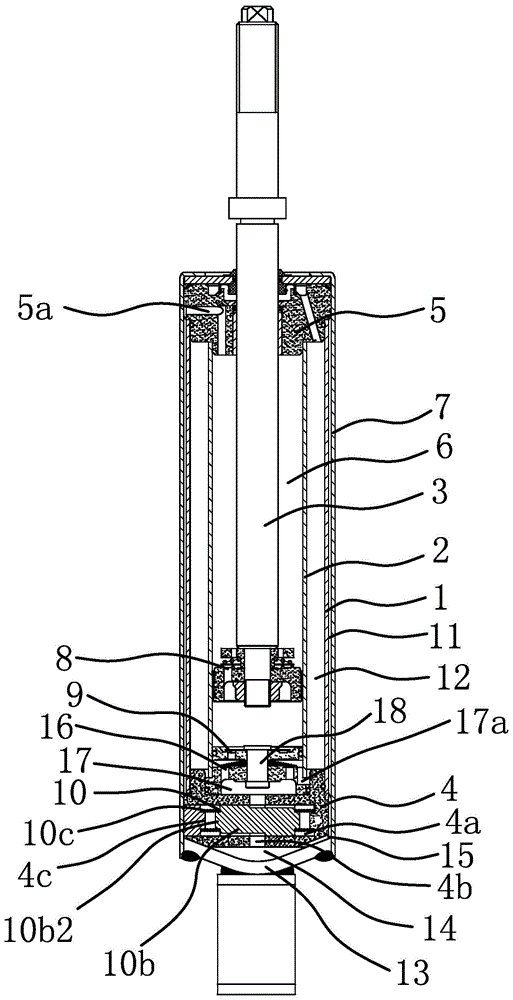

[0038] like image 3 As shown, the structure and principle of this embodiment and Embodiment 1 are basically the same, the difference is that in this embodiment, the inertia valve 10 includes a valve core 10b and a pair of springs 10c, and a pair of springs 10c are respectively located on the two sides of the valve core 10b. On both ends of the spool 10b, there are a pair of protruding positioning blocks 10b2, and the base 4 has a pair of protruding positioning blocks 4c. One end of the spring 10c is set on the positioning block 10b2, and the other end is set on the positioning block 10b2. On the second positioning block 4c, the first positioning block 10b2 and the second positioning block 4c play a role in positioning the spring 10c.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com