Automatic snow melting steel structure roof board

A panel, self-melting technology, applied to roofs, roof coverings, roofs using flat/curved panels, etc., can solve problems such as inability to melt snow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

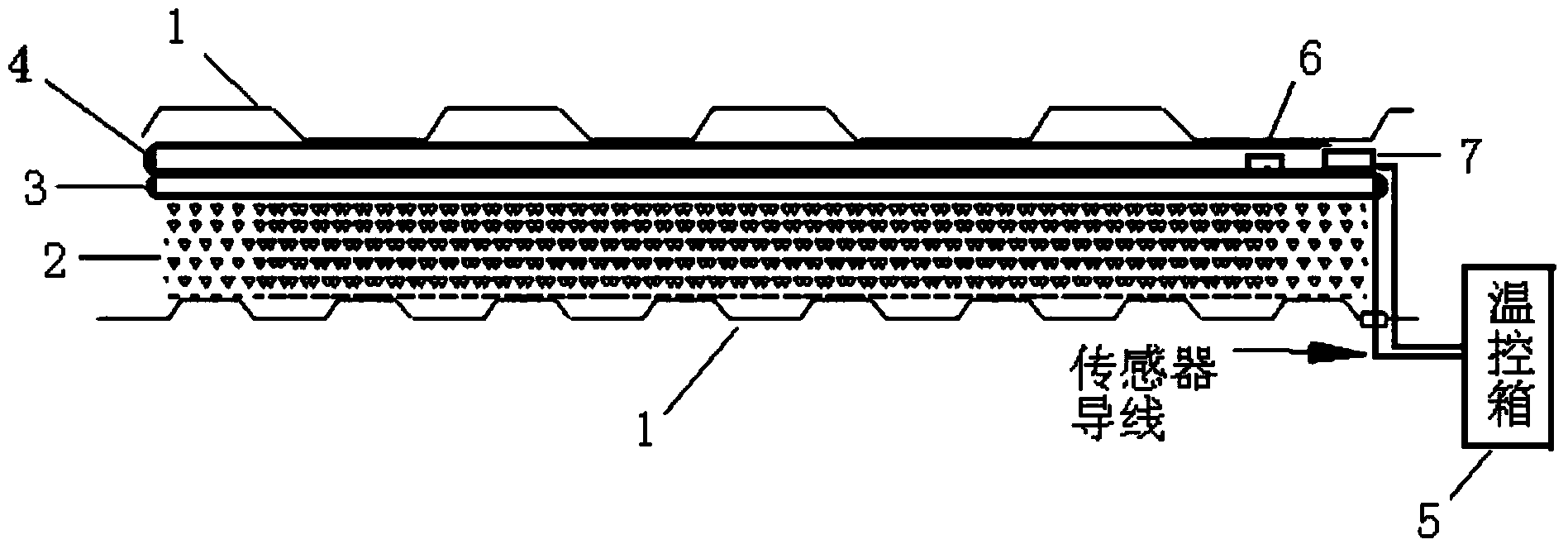

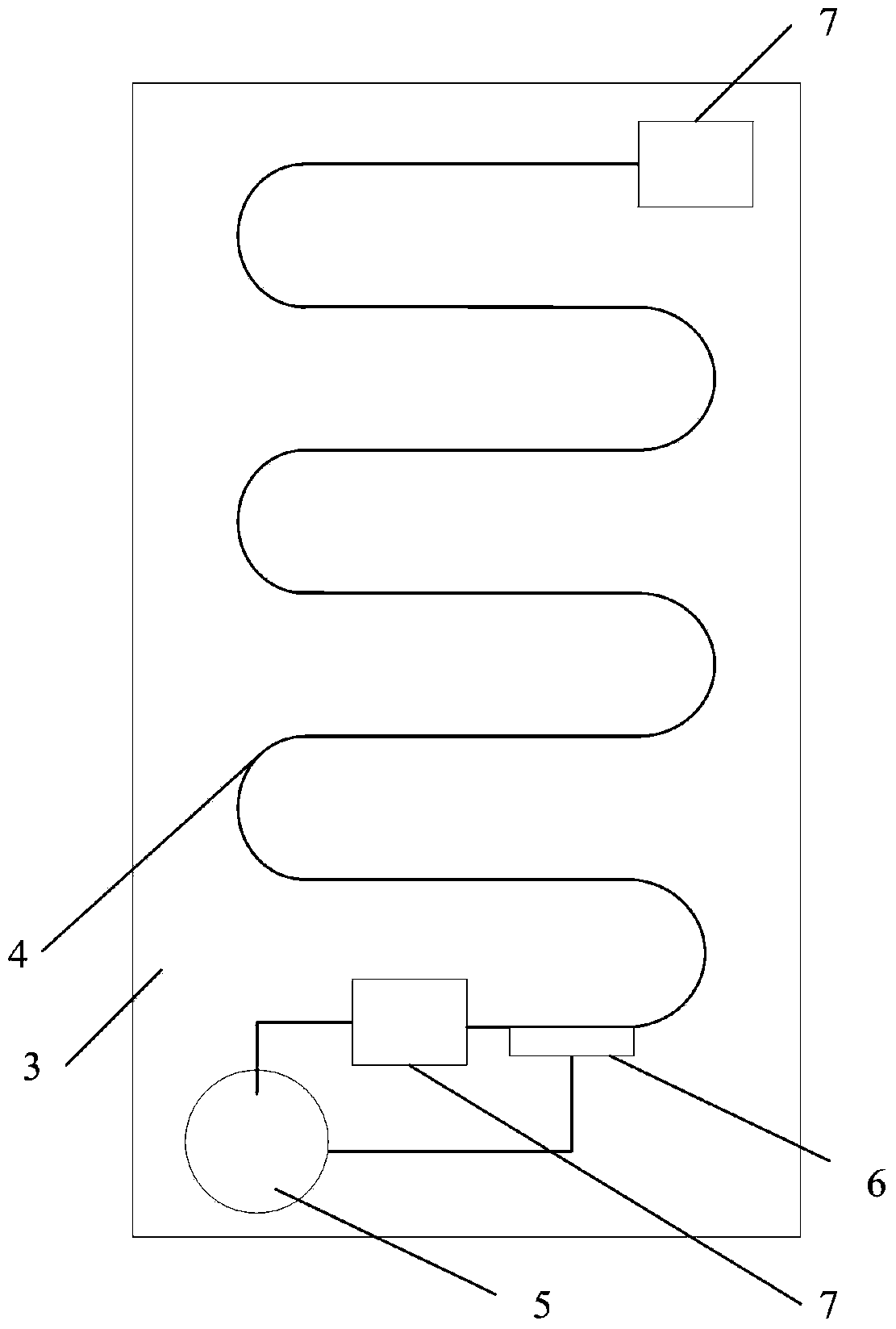

[0009] Specific implementation mode 1. Combination figure 1 with 2 Describe this embodiment, a self-melting snow steel structure roof panel, including a temperature control box 5, a temperature sensor 6 and two layers of protective layers, and also includes a thermal insulation layer 2 arranged in sequence from bottom to top in the two layers of protective layers 1, a metal heat conduction layer Layer 3 and snowmelt line 4; the temperature sensor 6 is connected to the temperature control box 5, and the snowmelt line 4 is connected to the power line through injection molded cold and hot joints 7; the temperature control box 5 is connected to the power box.

[0010] The material of the heat insulation layer described in this embodiment is any one of rock wool, rock wool board, extruded board, benzene board, glass wool board or glass wool felt; the material of the heat conduction layer can be heat conduction aluminum film, heat-conducting aluminum plate or heat-conducting copper...

specific Embodiment approach 2

[0013] Specific Embodiment 2. The self-melting snow steel structure roof panel described in this embodiment includes a power supply box and two layers of protective layers, and also includes a heat insulation layer, a metal heat conduction layer and an electrical insulation layer arranged in sequence from bottom to top in the two layers of protective layers. Heating cable; the electric heating cable is connected with the power box. Since the electric heat tracing has a self-limiting temperature function, the second method can be used without a thermostat and a temperature sensor. The snow melting control of the self-melting snow roof panel described in this embodiment can be performed in various ways, either manually or automatically, and can also be remotely controlled through the Internet and mobile phones.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com