A fire-resistant setting method for automobile combustion in long-span suspension bridges

A suspension bridge and long-span technology, applied in suspension bridges, bridge construction, bridges, etc., can solve the problems of casualties, tensile ultimate bearing capacity and elastic modulus decline, and increase the difficulty of bridge repair, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

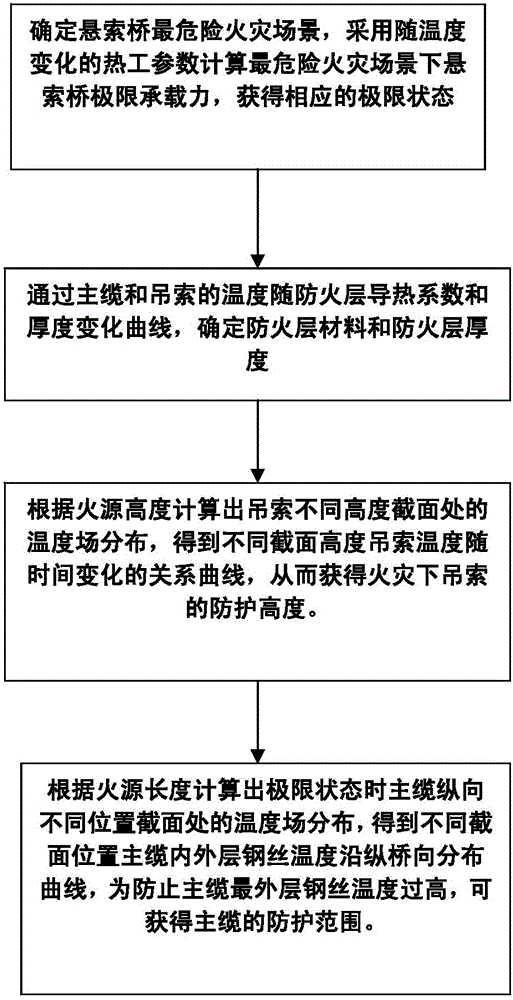

Method used

Image

Examples

Embodiment 1

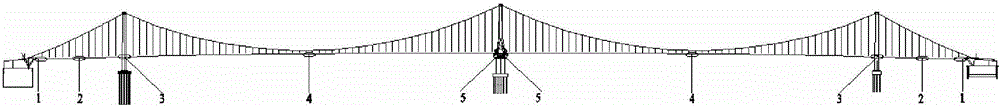

[0054] Embodiment 1, a fire-resistant setting method for a three-tower and four-span suspension bridge.

[0055] The span of the main bridge of a three-tower four-span suspension bridge is 200+2×850+200=2100m, the tensile strength of the main cable and sling at room temperature is 1770MPa, the diameter of the main cable is 70cm, and the diameter of the sling is 6.2cm. The tower is a herringbone steel tower, the side tower is a concrete tower, the main girder is made of q370QD, and the concrete slab is made of C60 concrete.

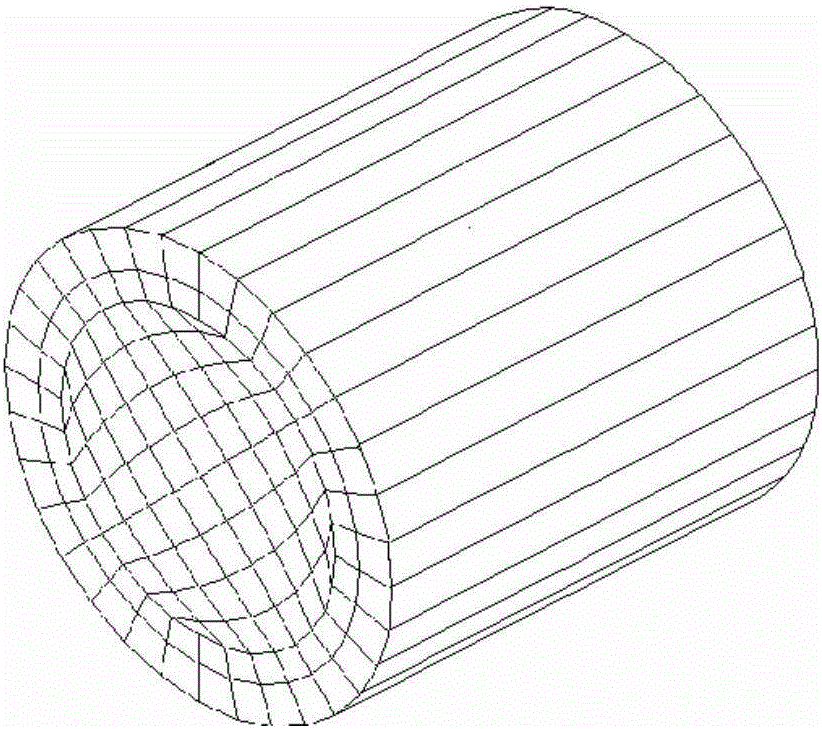

[0056] (1) The finite element software ANSYS is used to establish a three-dimensional space thermal-structural coupling refined finite element model of the three-tower four-span suspension bridge, as shown in figure 2 . The total length of the bridge is 200+850+850+200=2100 meters, with a total of 143 sections. The main girder is a hybrid model of space beam unit + space plate shell unit. There are 14 refined segments of space shell unit in the main gir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com