Source bottle applied to atomic layer deposition equipment

A technology of atomic layer deposition and source bottle, which is applied in the field of source bottle, can solve the problems of not being able to effectively increase the amount of saturated steam in the liquid source, and has no obvious effect, and achieve improved carrying efficiency, easy implementation, and good process stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

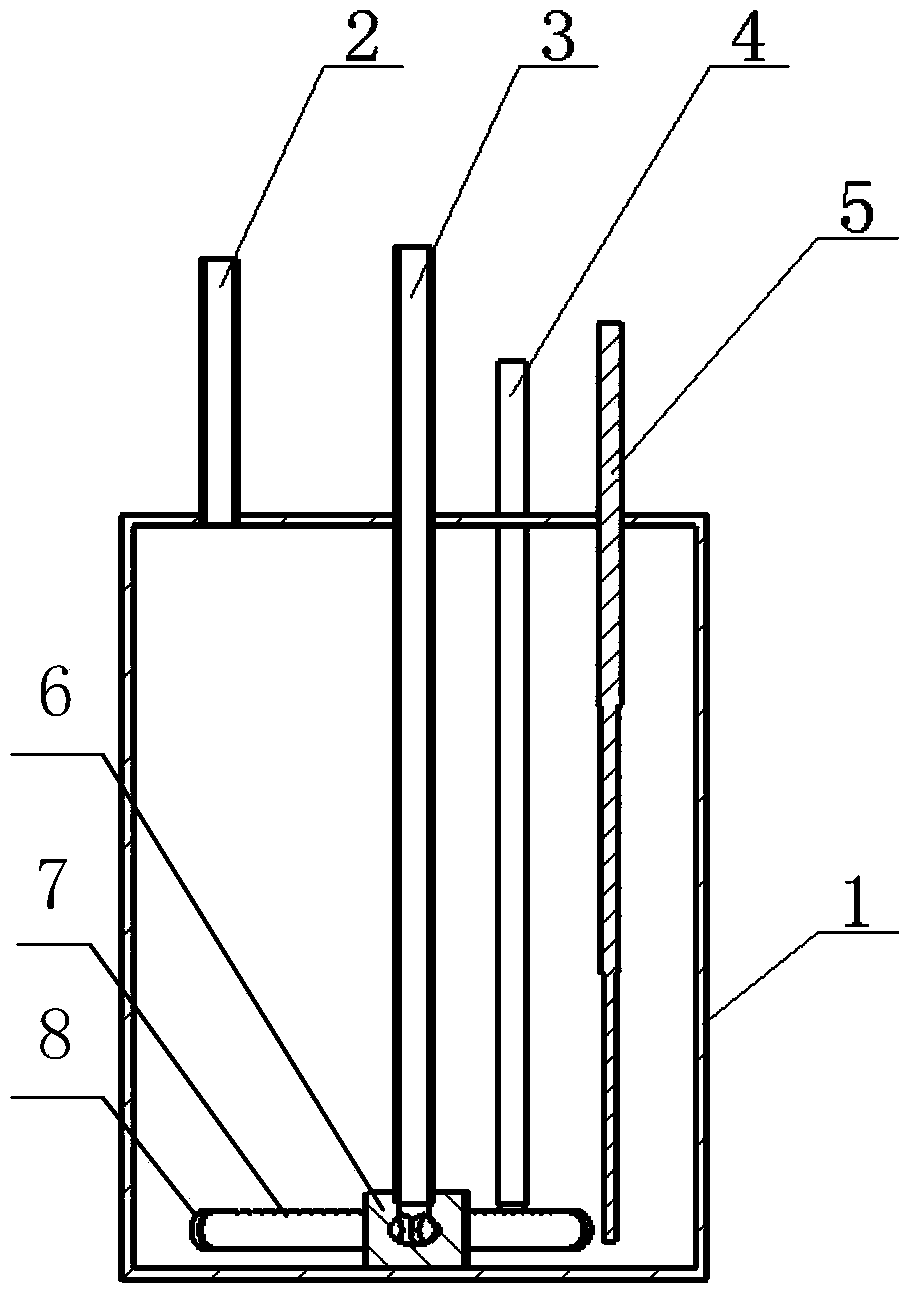

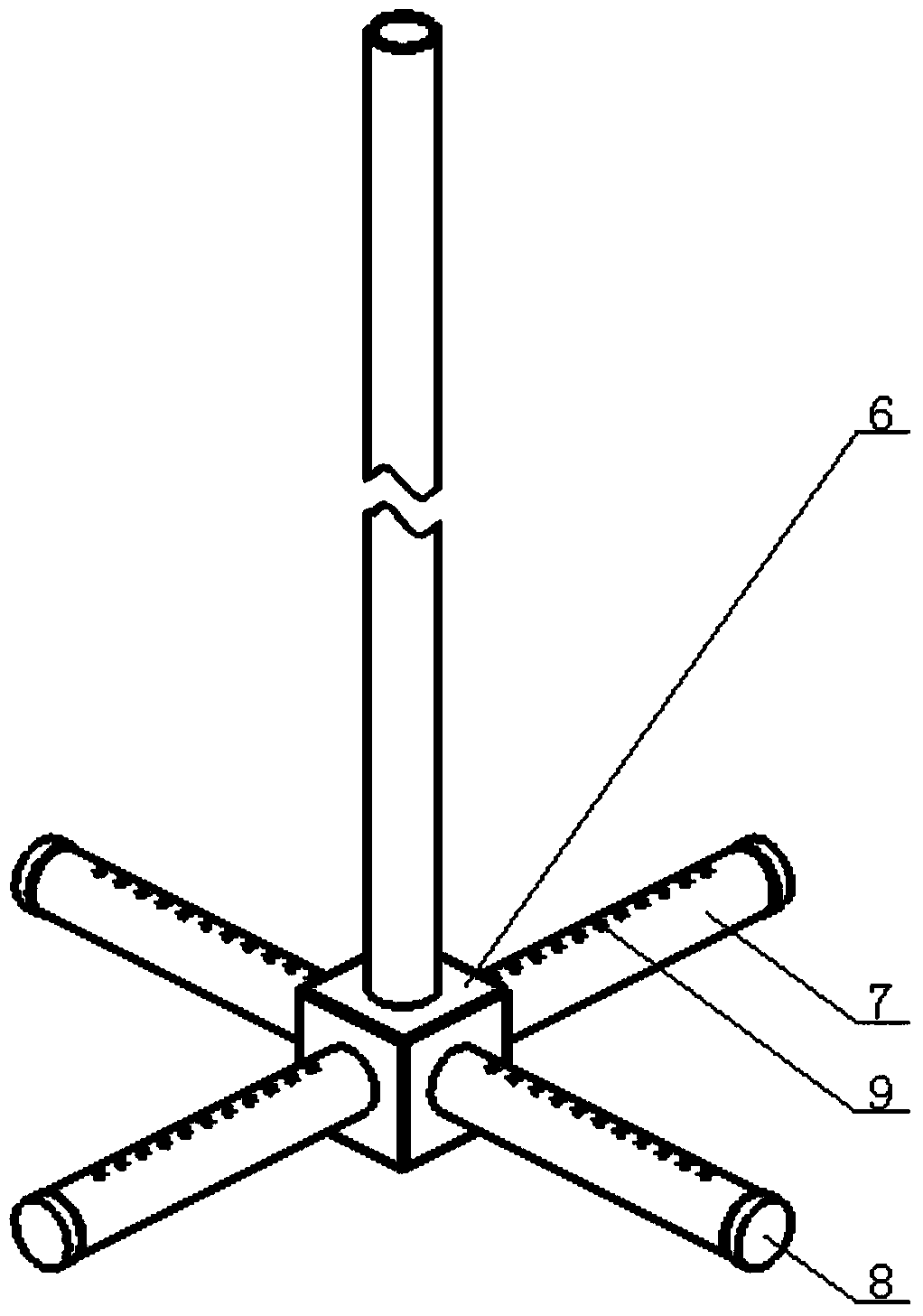

[0029] In this example, see figure 1 , figure 1 It is a schematic diagram of the cross-sectional structure of the source bottle of the present invention. As shown in the figure, the source bottle of the present invention includes a bottle body 1, and the top of the bottle body 1 is provided with an air inlet, an air outlet, a temperature sensor interface and a liquid level sensor interface through the inside and outside. The air inlet pipe 3 extends into the vicinity of the bottom of the bottle body 1 through the air inlet, and is sealed and welded together with the bottle body 1 at the top air inlet of the bottle body 1 . One end of the air inlet pipe 3 located outside the bottle body communicates with the carrier gas source, and the bottom end in the bottle body 1 is sealed and welded to the inlet of the five-way joint 6 . Four equal-length and equal-diameter bubbling tubes 7 with circular cross-sections are horizontally distributed in a cross shape, and one end is sealed ...

Embodiment 2

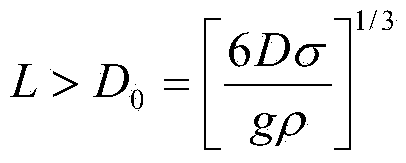

[0042] In this embodiment, the diameter of the air hole 9 on the bubbler tube 7 is set to be 1.0 mm, according to the relational formula between the air hole diameter D and the bubble diameter D0: The bubble diameter can be obtained as 3.54mm (wherein, the density of water at room temperature (21°C) ρ=1.0×10 3 kg / m 3 , the surface tension coefficient of water at room temperature (21°C) σ=7.266N / m, and the acceleration of gravity g=9.8m / s2). Therefore, the hole spacing between the adjacent air holes 9 on the bubbling tube 7 should be greater than 3.54mm, so it is rounded to 4.0mm. Other structural settings and conditions in this embodiment are the same as those in Embodiment 1, and will not be expanded here.

[0043] It should be noted that when the bubbles generated by the carrier gas are rising, the liquid source liquid will gradually spread to the inside of the bubbles and gradually reach saturation. Comparative analysis embodiment one and embodiment two, because the bub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com