Split type girder moving crane

A crane and split technology, which is applied in the field of split beam-moving cranes, can solve problems such as limiting the hoisting range of the crane, and achieve the effects of increasing the hoisting range, reducing the overall weight, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

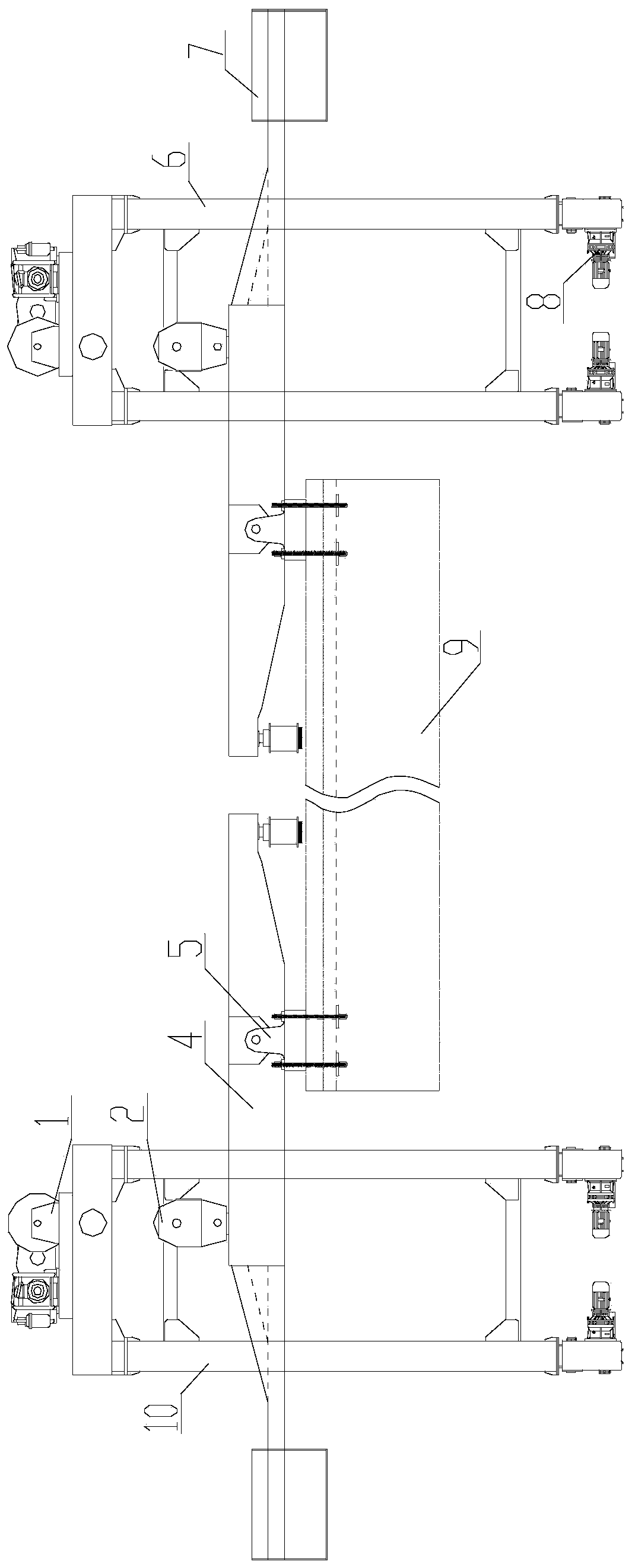

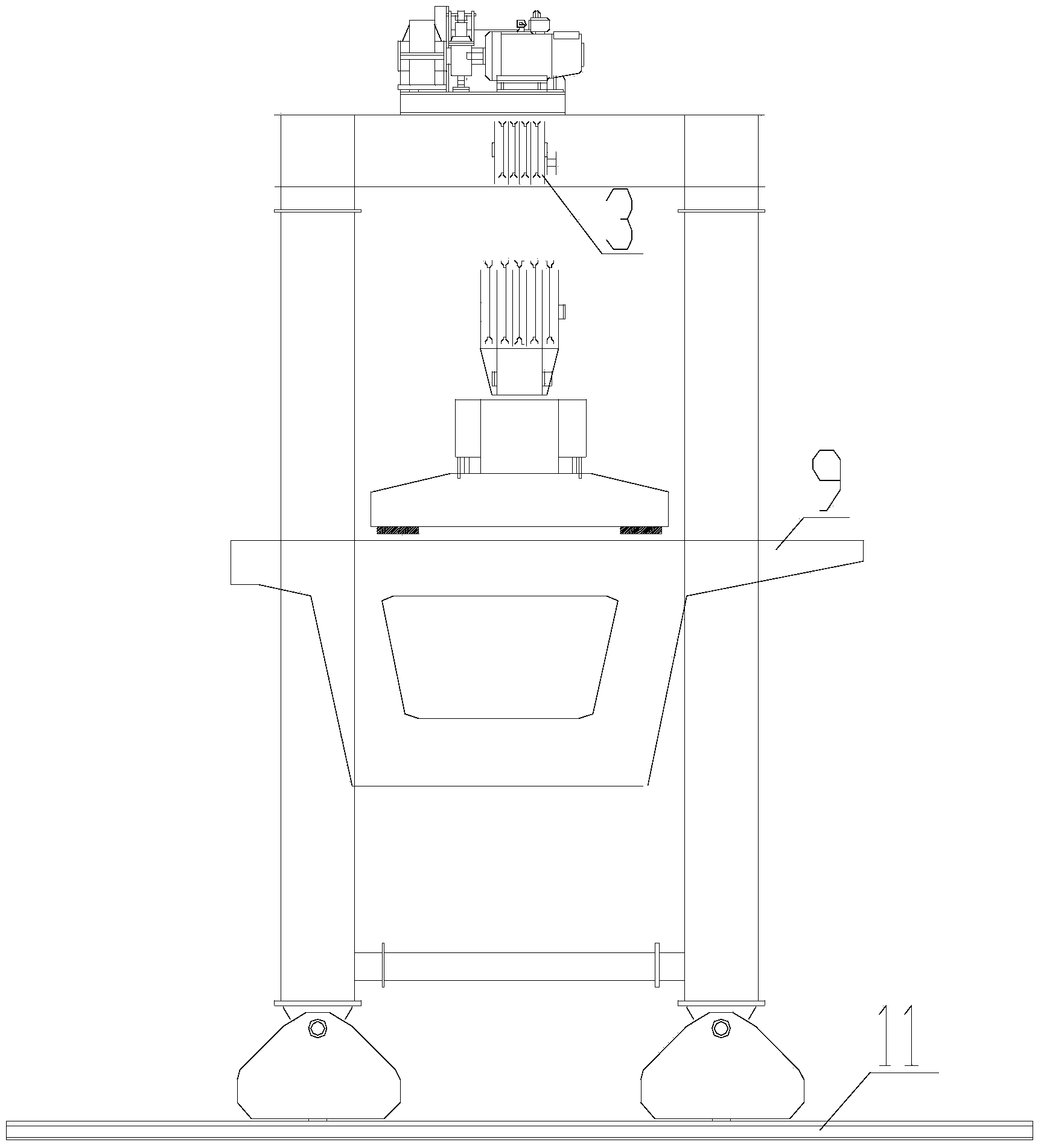

[0013] Embodiment: split type beam moving crane, such as figure 1 with figure 2 As shown, it includes a left crane frame and a right crane frame, and the top of the left crane frame and the right crane frame is provided with a winch, and a fixed pulley block is arranged on the winch, and the fixed pulley block is connected with the movable pulley block, and the movable pulley block It is connected with the pole of the hanging beam; the bottom of the frame of the left crane and the frame of the right crane is equipped with a traveling mechanism to control the movement of the split beam moving crane along the track; the pole of the hanging beam is equipped with a counterweight for balancing the hanging beam A shoulder pole; a spreader is arranged on the pole of the hanging beam.

[0014] When working, the bridge components are first fixed on the suspension girder shoulder pole by the spreader, and after the bridge components are anchored, the winches on the left crane frame an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com