Temperature-controllable cryogenic cooling device

A cooling device, low temperature technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment and other directions, can solve the problems of reducing the fatigue strength of parts, large deformation, and the cooling effect is difficult to meet the processing needs, to solve the milling problem , the cooling effect is significant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

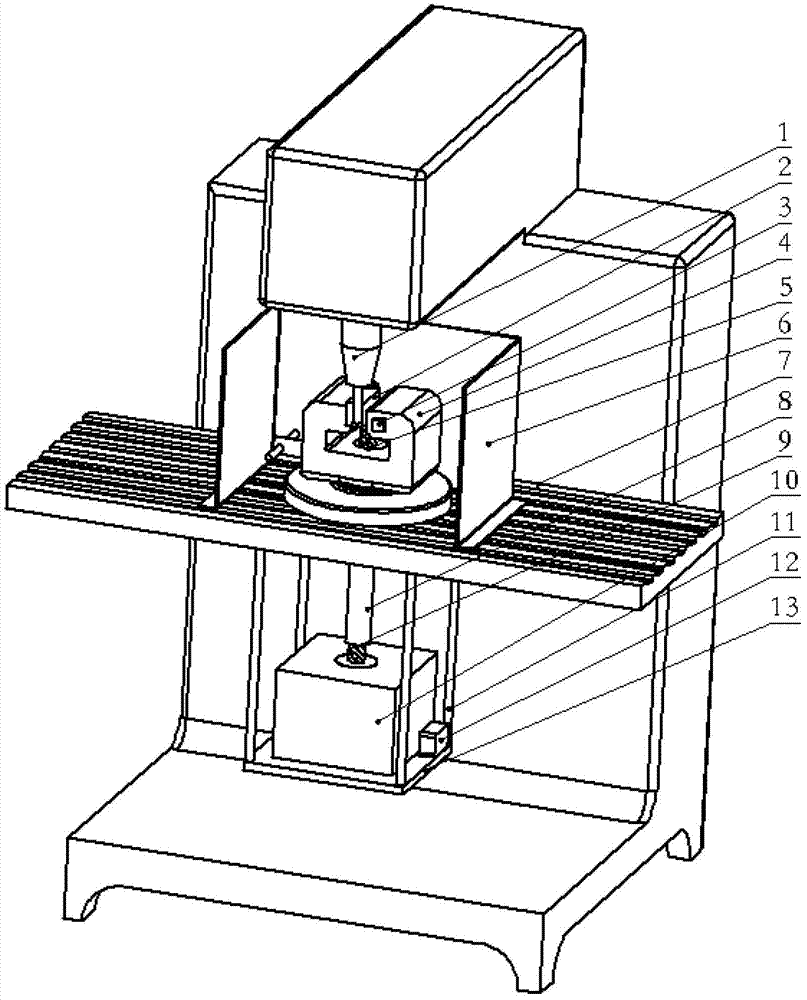

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0021] Such as figure 1 A temperature-controllable cryogenic cooling device shown includes a fixture 4, a heat transfer member connected to the fixture 4, and a liquid nitrogen container 10 connected to the heat transfer member; the fixture 4 is preferably made of a material with good thermal conductivity, such as a copper fixture , the specifications can be selected according to the actual clamping requirements, mainly used for good heat conduction while clamping the processed material 2; the liquid nitrogen in the liquid nitrogen container 10 is used to absorb a large amount of heat during vaporization, thereby cooling the heat transfer member, The thermal component cools the processed material 2 clamped by the fixture 4 through heat conduction, and at the same time takes away the heat generated during milling, which solv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com