Turnover lifting mechanism

A technology of turning up and down and flipping boards, which is applied in hoisting devices, metal processing, hoisting devices, etc., and can solve problems such as large errors, increased production costs, and affected product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

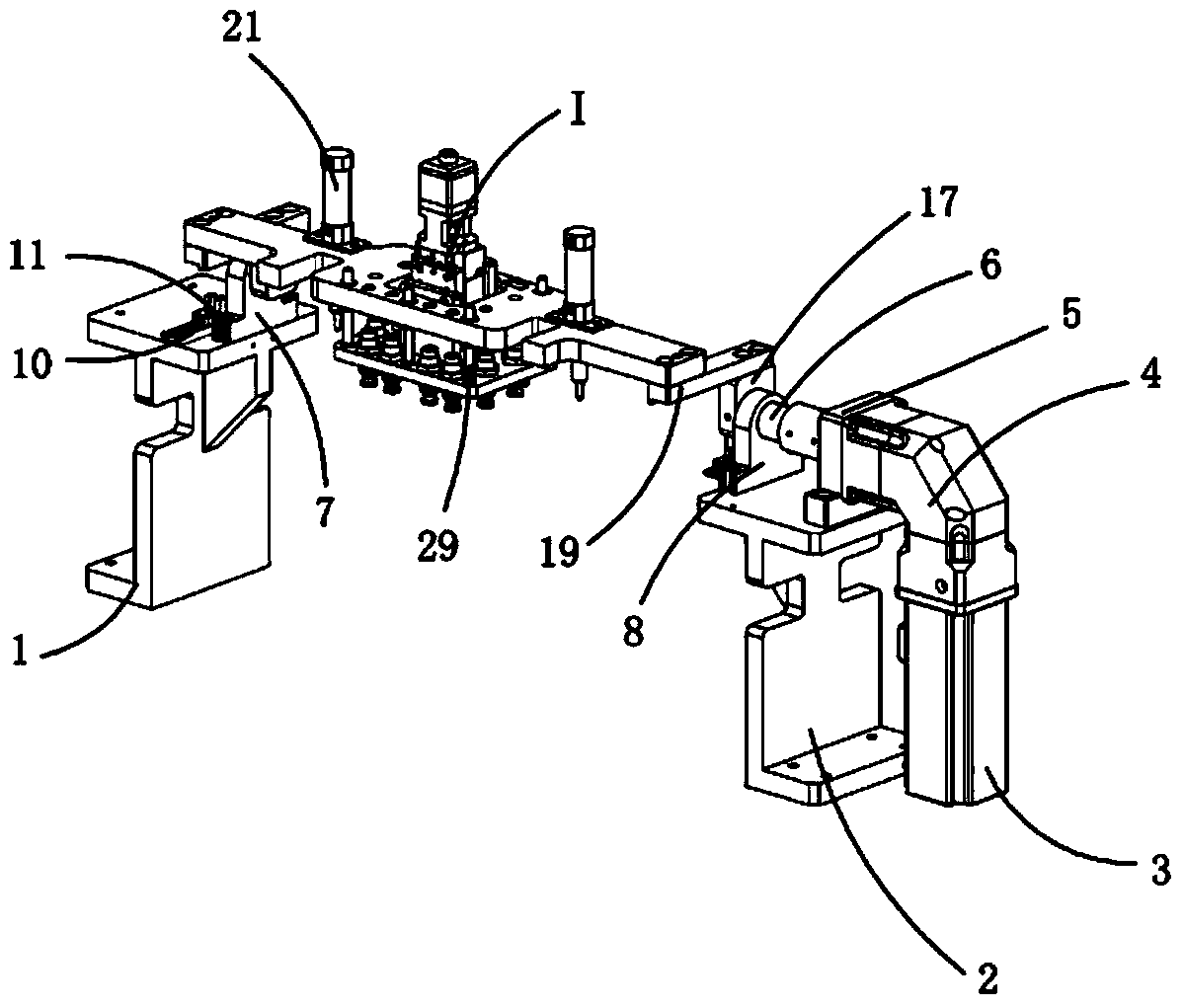

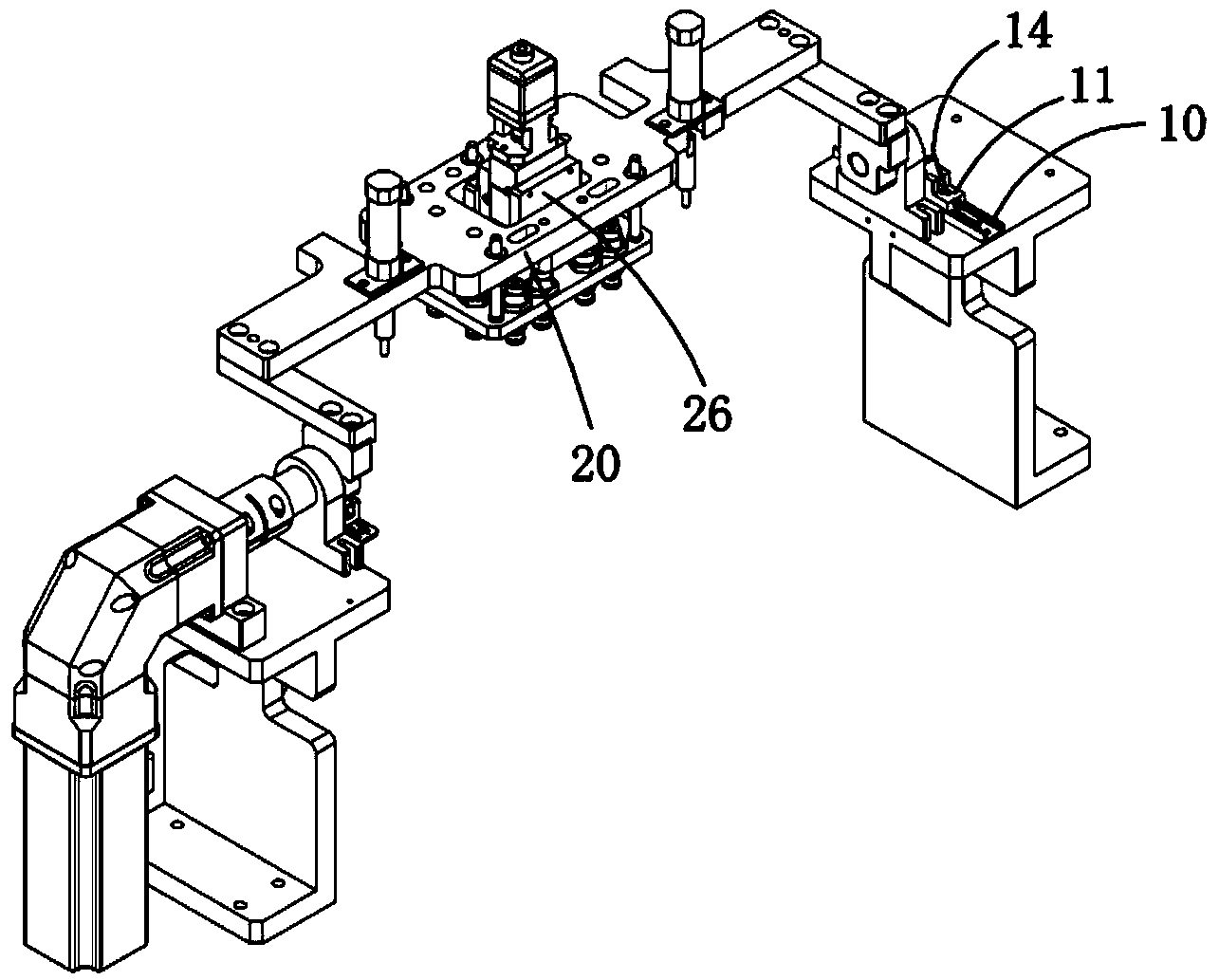

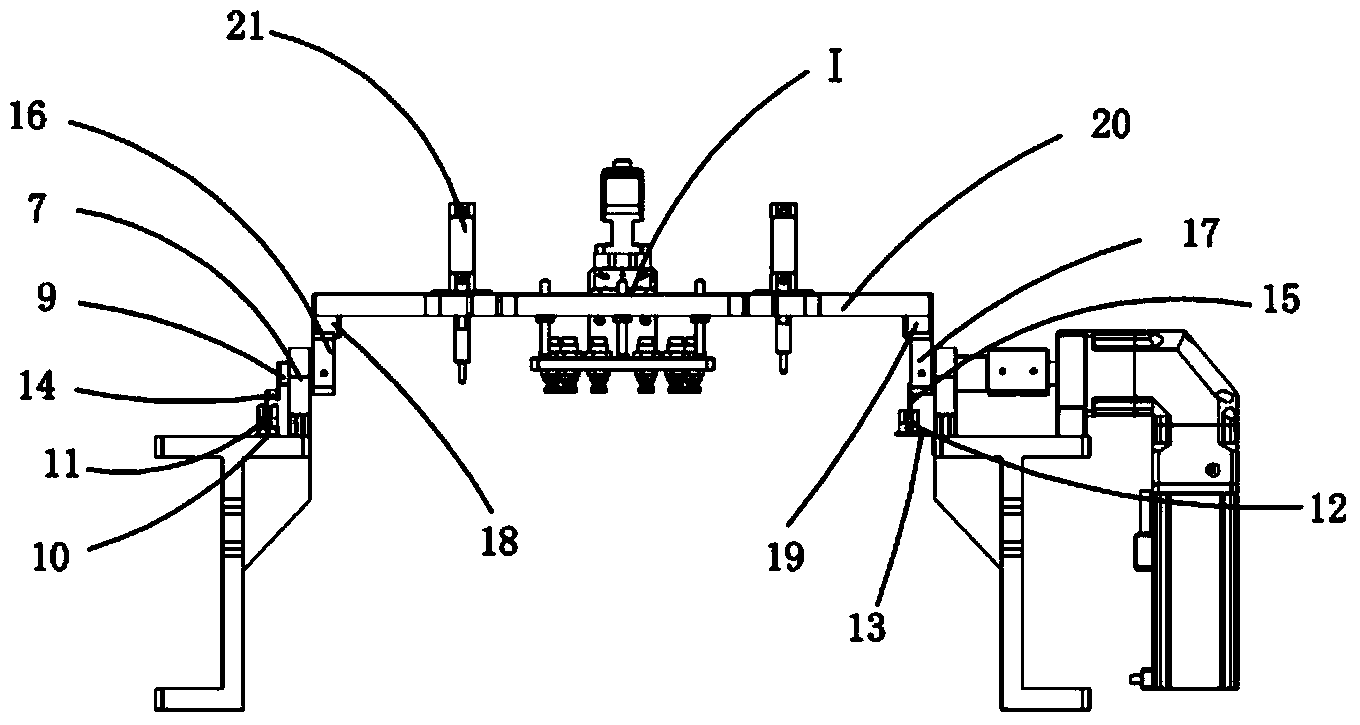

[0022] Examples, see attached Figure 1~4 , a flip lifting mechanism, which includes a left mounting seat 1, a right mounting seat 2, a driving motor 3, a right-angle reducer 4, a reducer fixing seat 5, a rotating shaft 6, a left rotating shaft supporting seat 7, and a right rotating shaft supporting seat 8 , rotating shaft 9, mounting strip 10, left photoelectric sensor 11, right photoelectric sensor 12, right photoelectric sensor fixing seat 13, left sensing sheet 14, right sensing sheet 15, left rotating block 16, right rotating block 17, left connecting plate 18, The right connecting plate 19, the turning plate 20, the unlocking cylinder 21 and the turning assembly I, the mounting bar and the left rotating shaft support seat are fixedly installed on the left mounting seat, the rotating shaft is installed on the left rotating shaft supporting seat, and the rotating shaft is connected with the left rotating block Together, the left connecting plate is fixedly installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com