Double-station edging machine

A kind of edge cutting machine, double station technology, applied in the direction of manufacturing tools, metal processing equipment, metal sawing equipment, etc., can solve the problems of equipment vibration amplitude and noise, unfavorable product processing, limit processing efficiency and other problems, to ensure the working time , the effect of reducing trouble and reducing lift time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

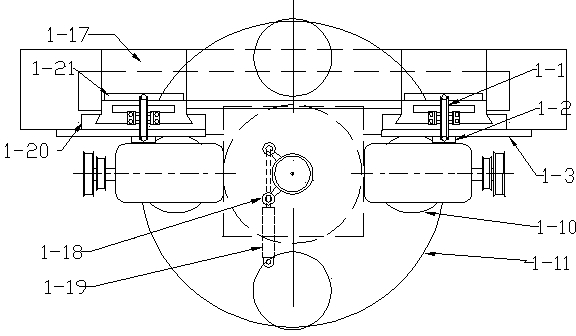

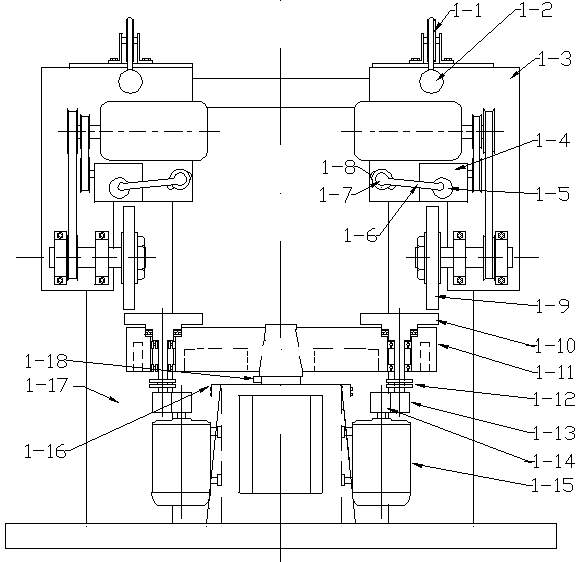

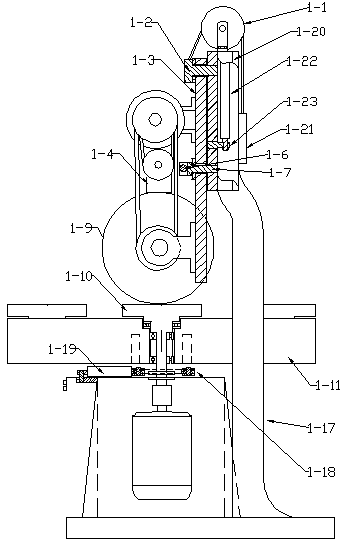

[0035] Specific implementation methods: such as figure 1 As shown, a double-station sharpening machine includes a square base, a main shaft is installed on the square base frame, and a circular workbench (1-11) is installed on the upper end of the main shaft. A circular workbench (1-11) is arranged on the frame, and four small turntables (1-10) are evenly distributed on the workbench (1-11), and the saw blades to be processed are on the small turntables 1-10. Each small turntable is a station, and the grinding wheel (1-9) for grinding the saw blade and the feed control device for driving the grinding wheel are arranged above the workbench (1-11), and the grinding wheel (1-9 ) is located on the grinding wheel support device and the lifting device, and the workbench (1-11) is provided with two processing stations and two waiting-to-be-processed stations. An electromagnet and a light touch switch (7-6) are installed on the small turntable (1-10), and the electromagnet passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com