Al-doped ZnO texture thermoelectric material manufacturing method

A thermoelectric material and texture technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, which can solve the problems of large grain size, reduced thermal conductivity, and unreported thermoelectric materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

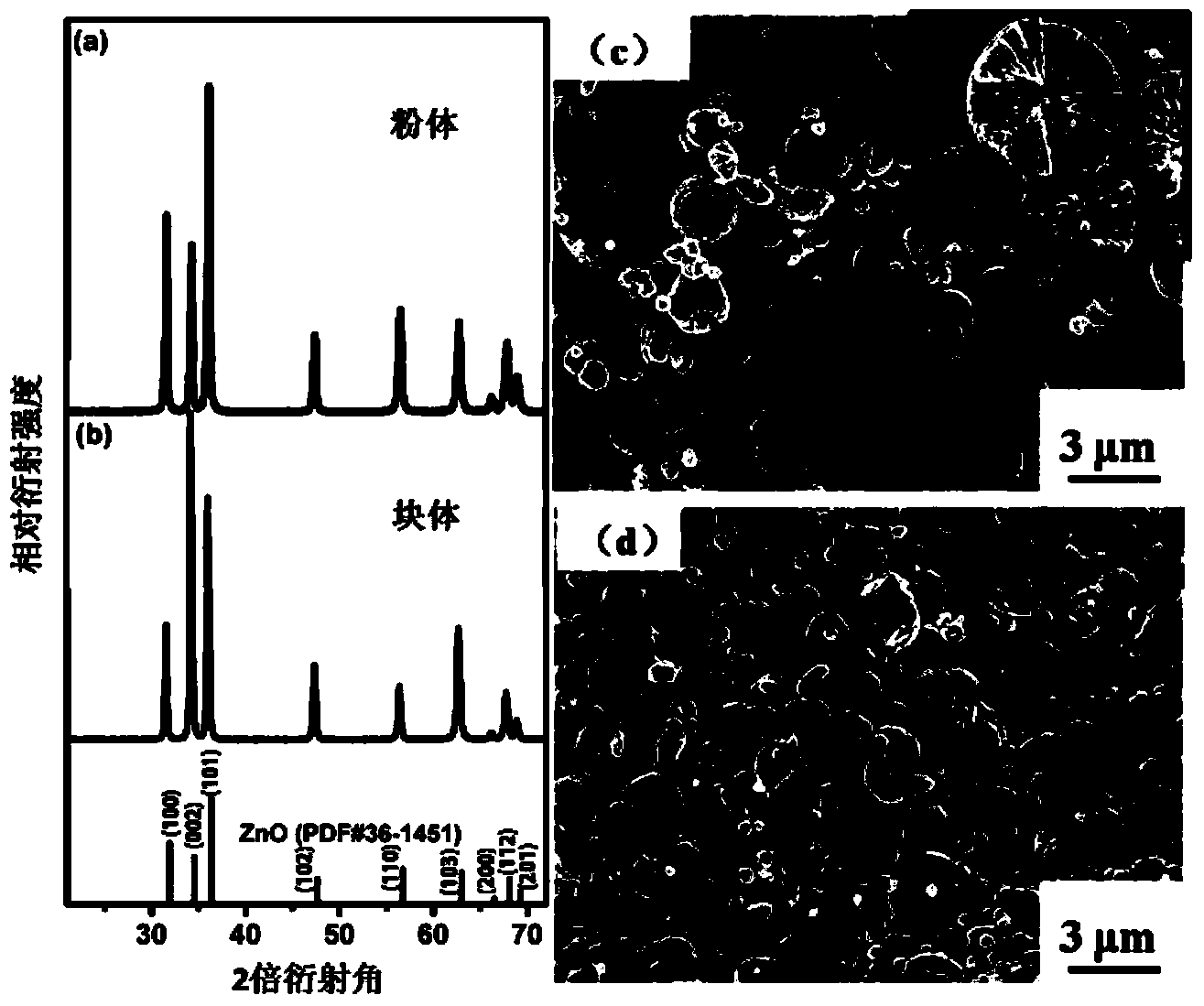

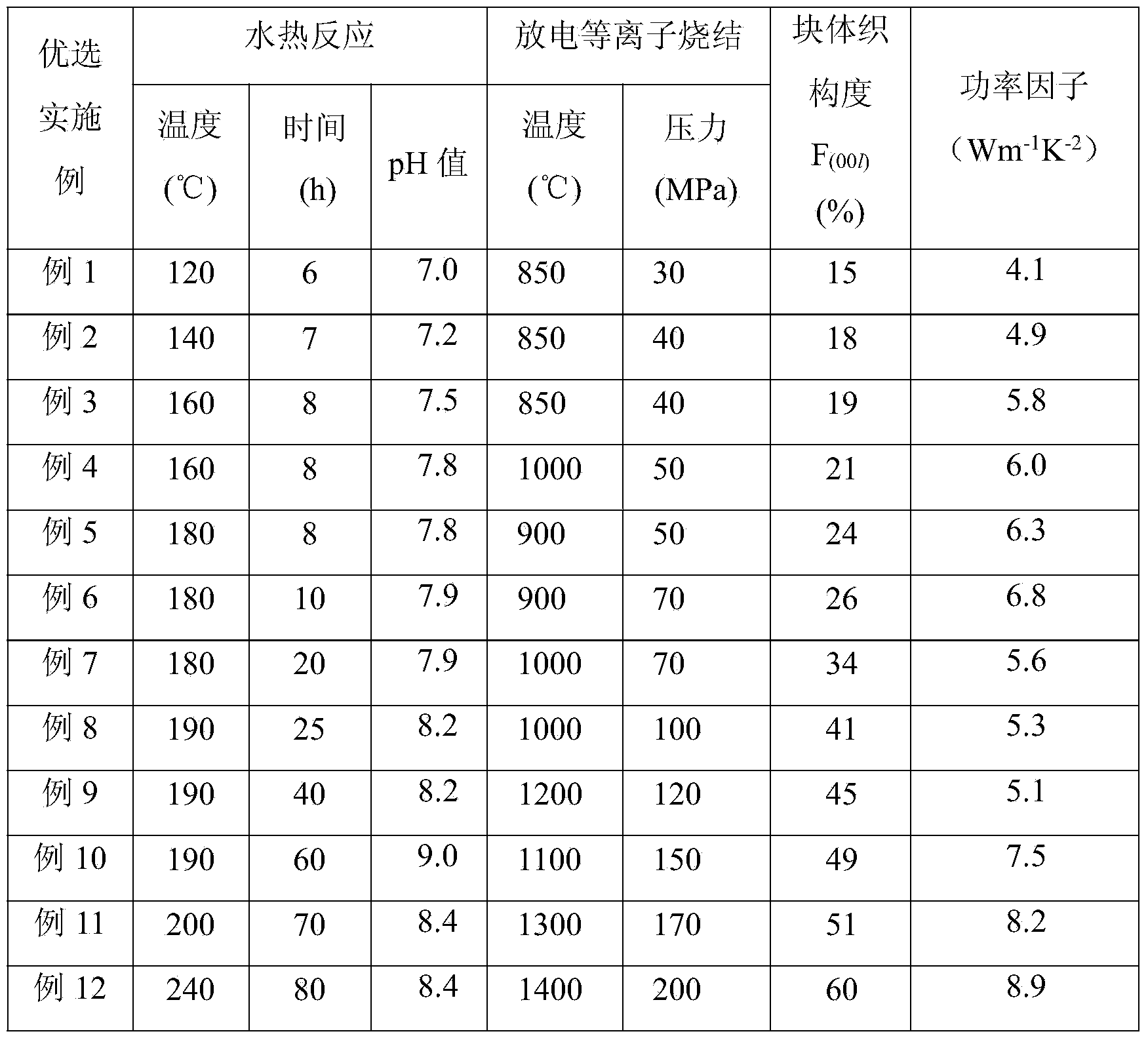

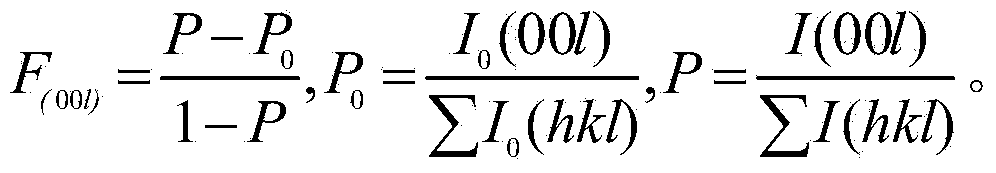

[0009] First, the Al-doped ZnO nanocomposite spherical precursor powder was prepared by hydrothermal method, and zinc acetate (Zn(CH 3 COO) 2 ·2H 2 O) (mass fraction greater than 99%) and aluminum nitrate (Al(NO 3 ) 3 ·9H 2 O) (mass fraction greater than 99%) as the raw material, according to the general chemical formula Zn 1-x Al x O(0.001≤x≤0.5mol) configuration, triethanolamine ((HOCH 2 CH 2 ) 3 N) As a surfactant, deionized water is used as a solvent to prepare Al-doped ZnO nanocomposite spherical precursor powder in a hydrothermal kettle. The nanocomposite spherical structure is characterized by the self-assembly of 10-800nm nanoparticles The diameter of the nano-composite sphere is 1-10 μm, and the (00l) axis of the nano-particles are arranged radially along the diameter direction of the micro-sphere. The nano-micro composite spherical precursor powder is subjected to spark plasma sintering to obtain an Al-doped ZnO bulk material with a grain size of 100-900 nm and a text...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com