Preparation method for Ga-doped ZnO texture thermoelectric material

A thermoelectric material and texture technology, which is applied in the ion sintering process to prepare Ga-doped ZnO textured thermoelectric materials, can solve the problems of large grain size and reduced thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

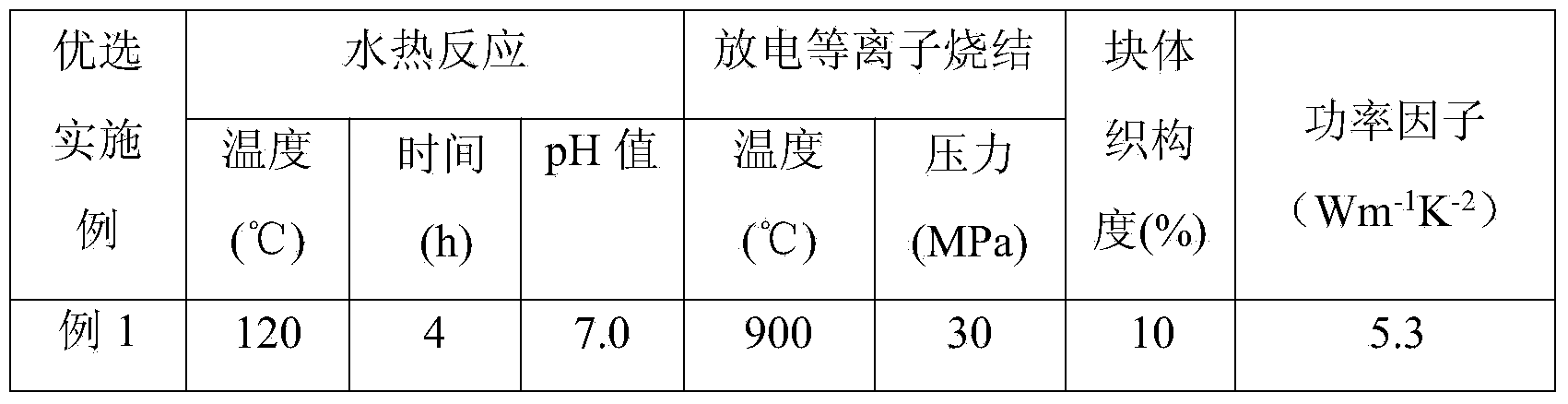

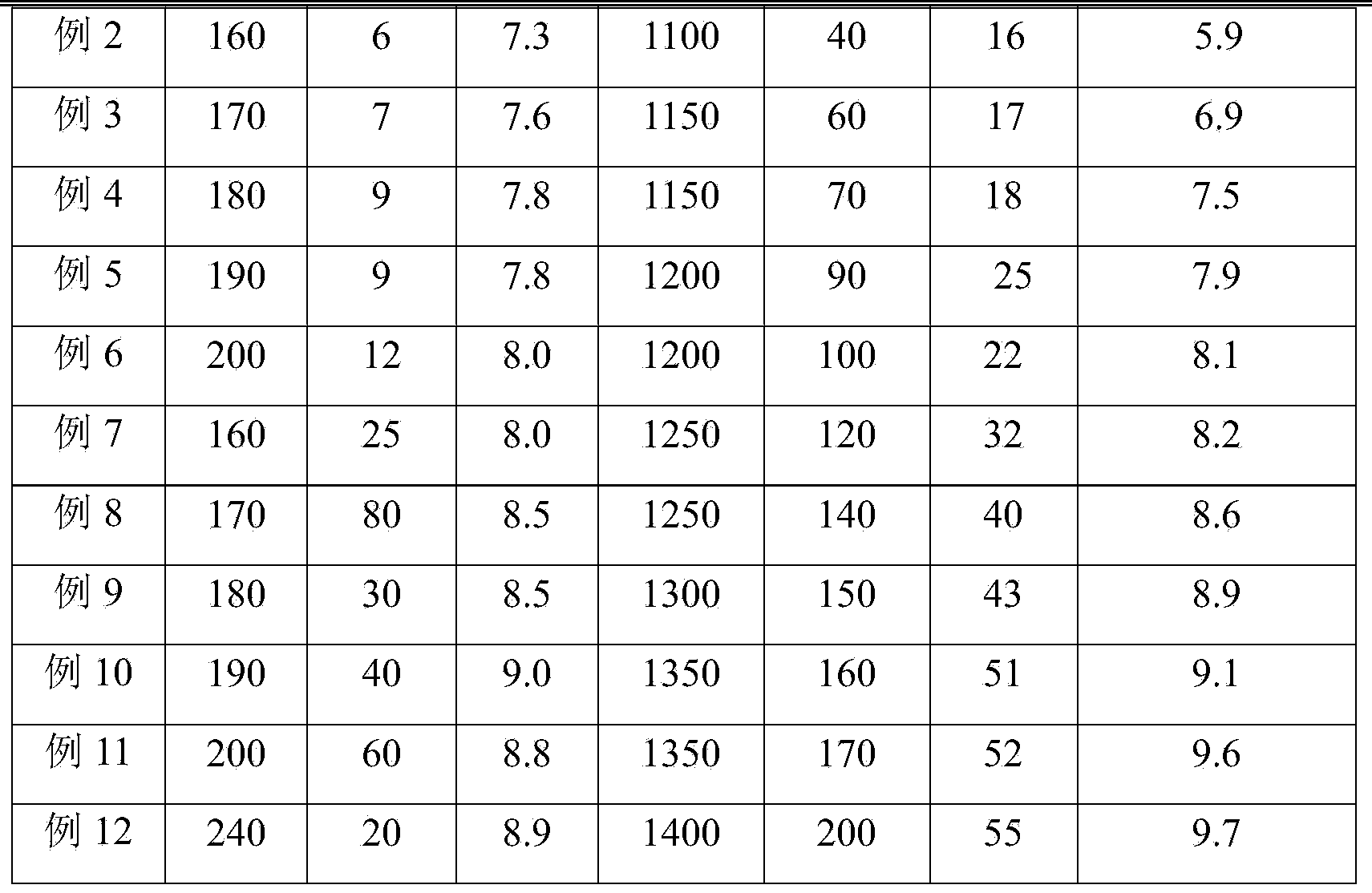

[0010] First, the Ga-doped ZnO nano-microcomposite spherical precursor powder was prepared by hydrothermal method, and zinc acetate (Zn(CH3 COO) 2 ·2H 2 O) (mass fraction greater than 99%) and gallium nitrate (Ga(NO 3 ) 3 ·xH 2 O) (mass fraction greater than 99%) is the raw material, according to the general chemical formula Zn 1-x Ga x O(0.001≤x≤0.5mol) configuration, triethanolamine ((HOCH 2 CH 2 ) 3 N) As a surfactant and deionized water as a solvent, a Ga-doped ZnO nano-micro composite spherical precursor powder was prepared in a hydrothermal kettle. The formed nano-micro composite spheres have a diameter of 1-10 μm, and the (00l) axes of the nanoparticles are radially arranged along the diameter direction of the microspheres. The nano-micro composite spherical precursor powder is subjected to spark plasma sintering to obtain a Ga-doped ZnO bulk material with a grain size of 100-900nm and a texture degree of 10-55%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com