A kind of preparation method of natural mineral load type nanometer defluoride agent

A natural mineral and load-bearing technology, applied in the direction of chemical instruments and methods, silicon compounds, silicates, etc., can solve the problems of nano-material reunion and deactivation, secondary pollution of water bodies, etc., to avoid secondary pollution, prevent reunion, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) High-temperature activation treatment: 100 g of natural zeolite with a particle size of 1 mm was treated at a high temperature of 700 ° C for 8 hours;

[0043] (2) Acid activation treatment: add the zeolite after high temperature activation treatment to 200ml of 7% hydrochloric acid solution for acid activation treatment for 20 hours, then wash until the pH value is 6.5, then filter and dry;

[0044] (3) Alkali activation treatment: add the dried zeolite in (2) to 200ml of 10% sodium hydroxide solution for alkali activation treatment for 24 hours; then wash until the pH value is 7.5, then filter and dry;

[0045] (4) Metal salt reaction: add the dried zeolite in (3) to 150ml of aluminum chloride solution with a concentration of 4mol / L and react for 18 hours; then adjust the pH value of the solution to 5.5, then wash, filter, ℃ drying for 4.5 hours to obtain a natural mineral-supported nano-fluoride removal agent.

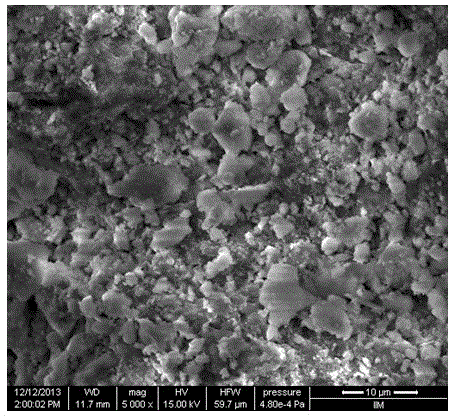

[0046] The scanning electron microscope picture of...

Embodiment 2

[0051] (1) High-temperature activation treatment: 100 g of natural zeolite with a particle size of 1.5 mm was treated at a high temperature of 400 ° C for 20 hours;

[0052] (2) Acid activation treatment: add the zeolite after high temperature activation treatment to 250ml of 2% hydrochloric acid solution for acid activation treatment for 48 hours, then wash until the pH value is 6, then filter and dry;

[0053] (3) Alkali activation treatment: add the dried zeolite in (2) to 150ml of 15% sodium hydroxide solution for alkali activation treatment for 12 hours; then wash until the pH value is 7, then filter and dry;

[0054] (4) Metal salt reaction: add the dried zeolite in (3) to 350ml of aluminum sulfate solution with a concentration of 0.3mol / L and react for 48 hours; then adjust the pH value of the solution to 6, then wash, filter, ℃ drying for 1 hour to obtain a natural mineral-loaded nano-fluoride removal agent.

Embodiment 3

[0056] (1) High-temperature activation treatment: 100 g of natural zeolite with a particle size of 3 mm was treated at a high temperature of 1000 ° C for 3 hours;

[0057] (2) Acid activation treatment: Add the zeolite after high temperature activation treatment to 100ml of 15% sulfuric acid solution for acid activation treatment for 6 hours, then wash until the pH value is 6.2, then filter and dry;

[0058] (3) Alkali activation treatment: add the dried zeolite in (2) to 100ml of 18% potassium hydroxide solution for alkali activation treatment for 12 hours; then wash until the pH value is 7, then filter and dry;

[0059] (4) Metal salt reaction: Add the dried zeolite in (3) to 105ml of aluminum nitrate solution with a concentration of 5mol / L and react for 12 hours; then adjust the pH value of the solution to 6, then wash, filter, and store Dry for 10 hours to obtain a natural mineral-loaded nano-fluoride removal agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com