Reaction rectification reactor

A reactive distillation and reactor technology, which is applied in the fields of fractionation, chemical methods for reacting liquid and gaseous medium, chemical instruments and methods, etc. The problems of large scope and large diameter of gas transmission pipeline can achieve the effect of uniform air intake, avoiding difficult connection and easy liquid level control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

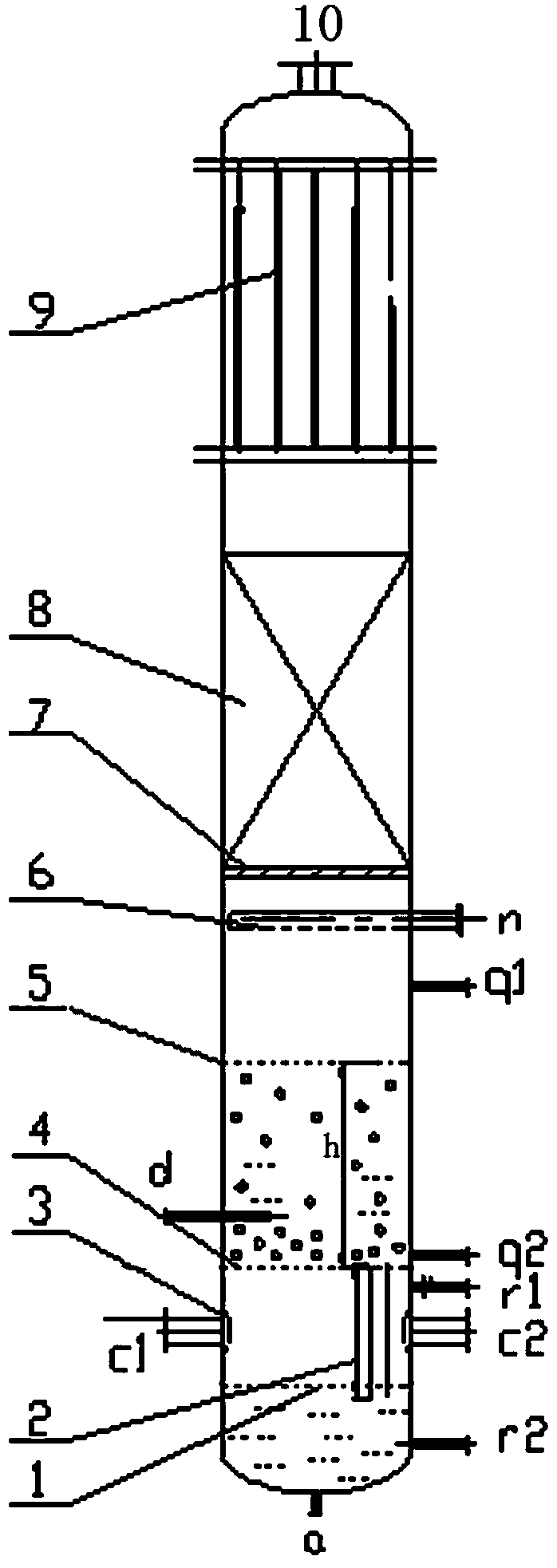

[0031] Such as figure 1 Shown is a schematic diagram of the reactor structure of this embodiment. From top to bottom, the reactor mainly includes three sections, which are respectively a reflux condensation section, a rectification section and a reaction section, wherein the reflux condensation section includes a condenser 10 and a heat exchange tube 9. The condenser 10 is directly installed on the top of the reactor, and the heat exchange tube 9 is installed inside the reactor. Below the heat exchange tube is the rectification section. The reactor adopts the form of a packed tower for rectification, that is, the Below the tube is packing 8 and a packing support plate 7 for supporting the packing, a liquid distributor 6 is arranged below the packing support plate 7, and a liquid inlet n connected to the liquid distributor 6 is arranged on the side wall of the reactor, The liquid inlet is also provided with an anti-shock plate 3, the reaction section is below the liquid distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com